2025 AIChE Annual Meeting

(546f) Sustainable Aviation Fuels Production: A Comparative Techno-Economic Study of Methanol-to-Jet, Fischer-Tropsch, and Novel Methanol-Based Fischer-Tropsch Processes

Authors

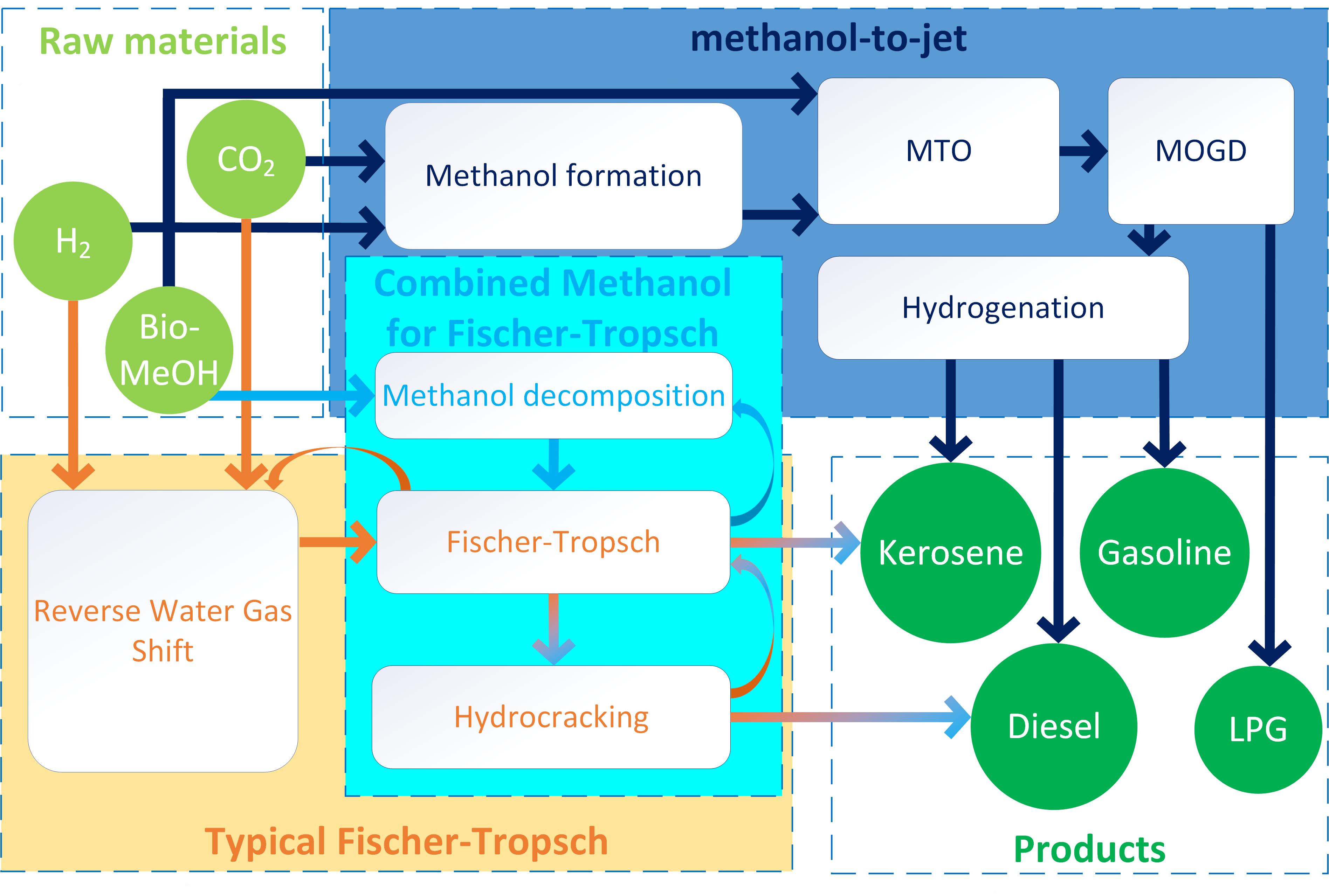

This work provides a techno-economic comparison of 3 different PtL SAF production processes presented in figure 1: i) from H2 and CO2 through Fischer-Tropsch production of hydrocarbons, ii) from H2 and CO2 to methanol followed by methanol-to-jet (MtJ) synthesis, and iii) methanol synthesis from biogas followed by Fischer-Tropsch production of hydrocarbons using methanol as the feed. The three processes are modeled and optimized using Aveva Process Simulation, while the economic assessment is performed with a Discounted Cash Flow Rate (DCFR) model in Python.

The Fischer-Tropsch process is modeled by feeding H2 from green electrolysis and CO2 from carbon capture to a Reverse Water Gas Shift (RWGS) reactor to obtain a stream with a H2:CO molar ratio of 2:1, further sent to the Fischer-Tropsch reactor. Olefins and paraffins are produced and transferred to distillation followed by hydrocracking to obtain C8 to C16 hydrocarbons.

Green H2 is also used as a feedstock for SAF production using the MtJ route. E-methanol is first produced (i.e., from green H2 and CO2) and sent to Methanol-To-Olefins (MTO) reactor to produce to C6 olefins. Longer olefins are further produced through the Mobil Olefins to Gasoline and Distillate (MOGD) process and finally hydrogenated to form kerosene.

Co-products, such as Liquefied Petroleum Gas (C3-C4 hydrocarbons), and diesel (C17+ hydrocarbons), are formed by both processes and gasoline (C4-C12 hydrocarbons) by the methanol-to-jet process only.

The DCFR model is applied by running a Monte-Carlo simulation with 1000 iterations accounting for the uncertainty of inputs as detailed by G. Sin [1]. The DCFR model gives a Levelized Cost of Operations (LCO) of $8.17±5.25/kg using the methanol-to-jet process and $5.10±2.51/kg using the Fischer-Tropsch process, lacking competitiveness with the current price of fossil jet fuel in Denmark ($0.68/kg). Sensitivity analyses highlight the substantial impact of H2 price (assumed $7.04±3.90/kg based on current European prices) on SAF costs, which necessitates exploring alternative renewable feedstocks for SAF. Our results show that substituting bio-methanol (i.e., from biomass-derived feedstock) to e-methanol, based on the average price from the Methanol Institute ($0.55/kg) [2], the LCO of SAF using MtJ process becomes $0.72/kg.

A third process is modelled, by using methanol as a feed to a Fischer-Tropsch synthesis process, as described in Figure 1, decreasing the number of processing steps. This pathway was described by Paterson and Sunley in their patent [3]. Methanol, assumed from biomass, is decomposed into H2 and CO in a 2:1 ratio at 300°C (against 940°C for the RWGS), which are then transferred to the Fischer-Trospch reactor.

By guiding feedstock choices for aviation’s net-zero goals, our study offers a viable path for SAF production and challenges e-methanol’s H2 dependency with two alternatives: the methanol-to-jet process using bio-methanol and the promising bio-methanol+Fischer-Tropsch process.

[1] Sin, G., Gernaey, K. V., Neumann, M. B., van Loosdrecht, M. C., & Gujer, W.. Global sensitivity analysis in wastewater treatment plant model applications: prioritizing sources of uncertainty. Water research, 45(2), 639-651; 2011.

[2] Innovation Outlook Renewable Methanol, Methanol Institute, Irena 2021. https://www.irena.org/publications/2021/Jan/Innovation-Outlook-Renewable-Methanol

[3] Alexander Jamers Paterson, Glenn Sunley, Fischer-Tropsch production of hydrocarbons from methanol. European Patent Office, https://patents.google.com/patent/EP4321597A1/en; 2024.