2025 AIChE Annual Meeting

(372b) Renewable Methanol Production Via Solid Oxide Electrolysis-Integrated Processes

Authors

Robert Braun - Presenter, Colorado School of Mines

Hassan Khan, Colorado School of Mines

Shane Conley, Colorado School of Mines

John Bogild Hansen, BogildConsulting

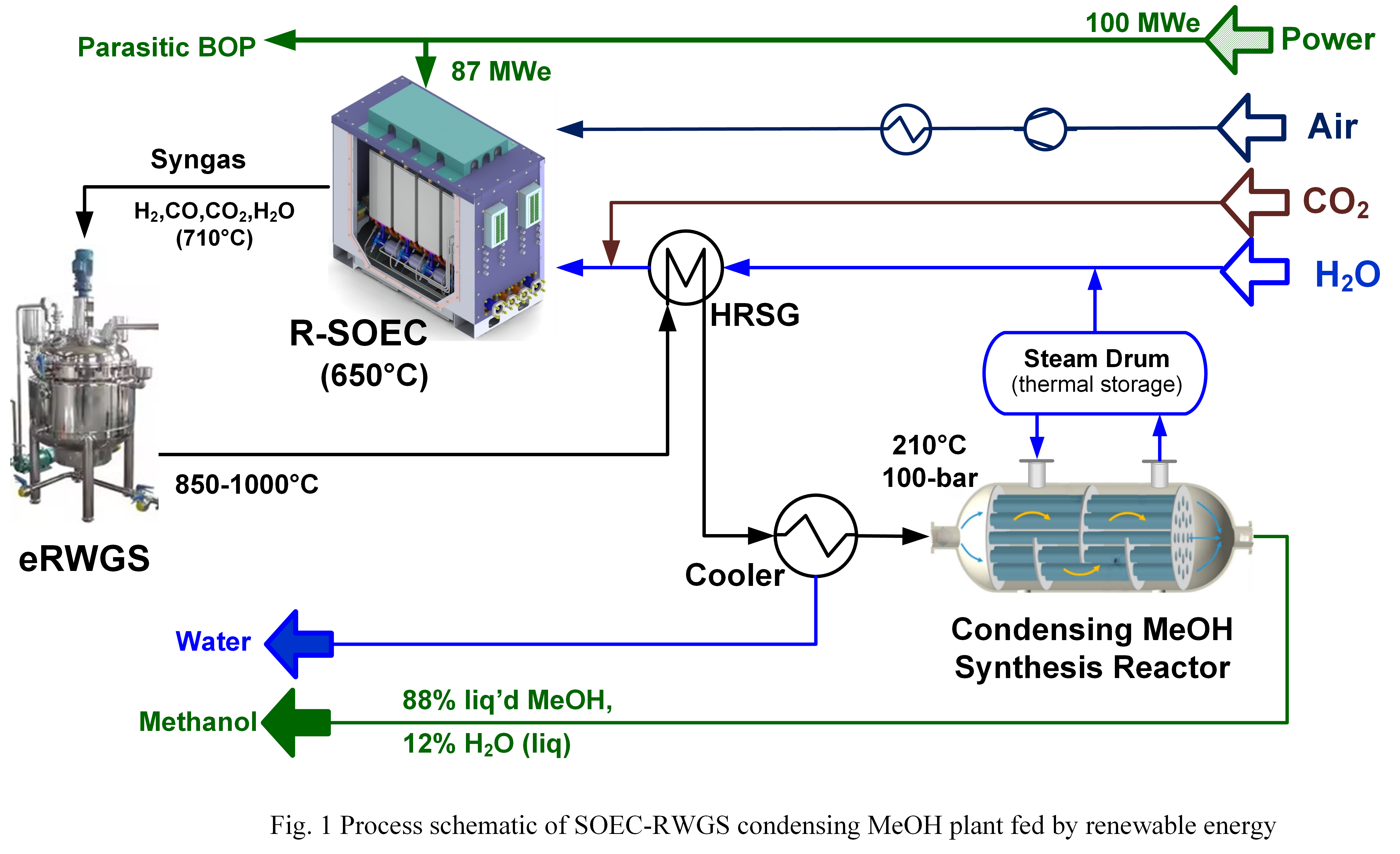

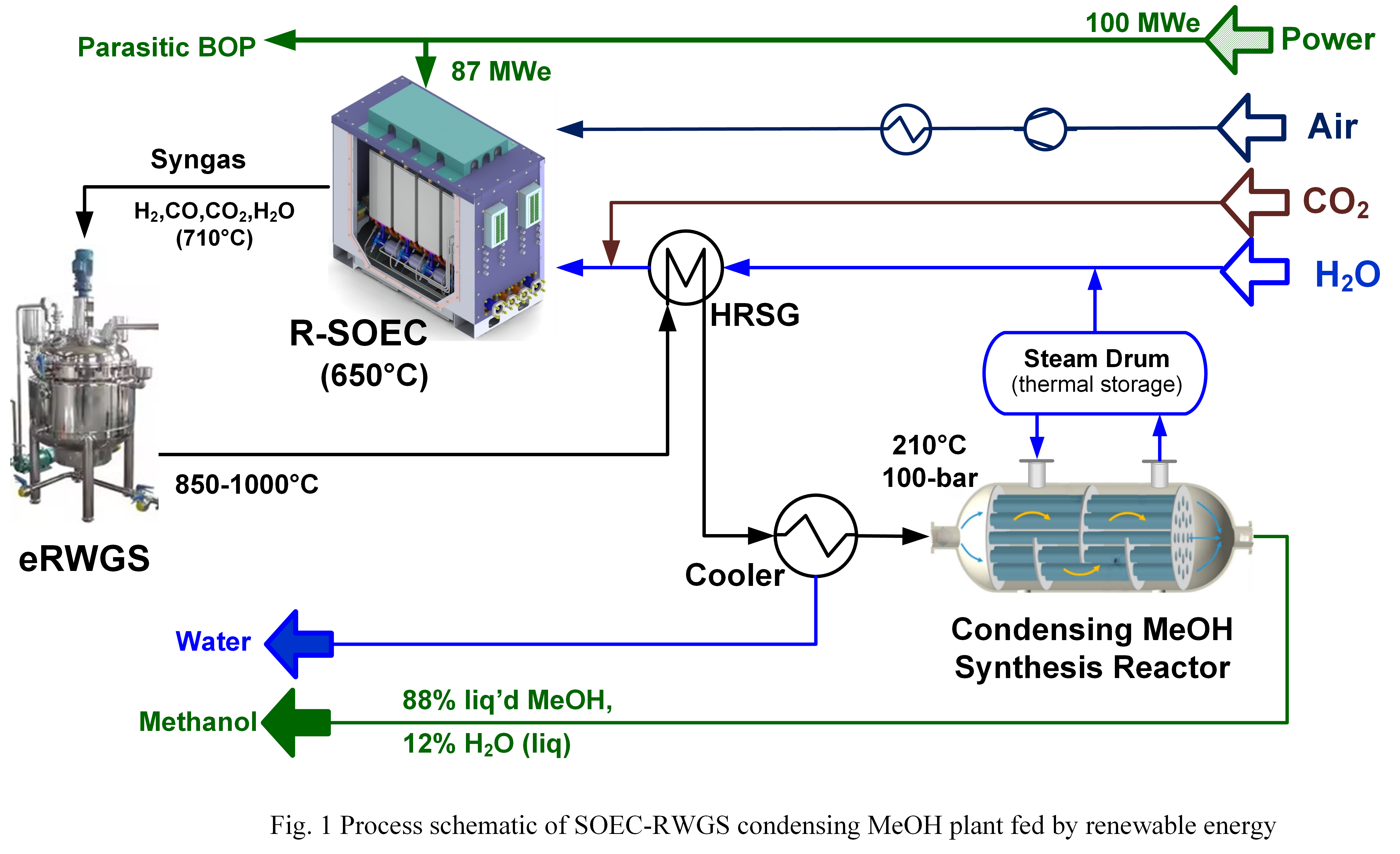

Renewable methanol (MeOH) production is essential for decarbonizing fuels and chemical feedstocks, but its economic competitiveness remains challenging. This work investigates high temperature solid oxide electrolysis cells (SOECs) as a potentially superior alternative to conventional syngas production routes within Power to Fuel systems. SOECs were selected due to their theoretical advantages, including high electrical efficiency specifically for syngas (H₂/CO) production and their unique capability for direct co-electrolysis. This feature enables the generation of tailored syngas ratios, simplifying downstream processes compared to methods requiring separate hydrogen production, and conditioning. The techno-economic feasibility of a novel 100 MWe SOEC-integrated process plant that couples SOEC co electrolysis (operating at 5 bar) with an electrically heated reverse water gas shift (eRWGS) reactor and a high conversion condensing methanol reactor was designed (See Fig. 1) and evaluated. The overall electrical to methanol efficiency and minimum selling fuel price (MSFP) for the conceptual plant were employed as primary performance metrics. Process simulations, using gPROMS for the SOEC unit and Aspen Plus for balance-of-plant modeling, were combined with a techno-economic analysis based on the DOE H2A framework. The integrated process demonstrated technical viability, achieving a simulated overall electric-to-methanol efficiency approaching 60% (LHV) in the base case. However, the estimated MSFP (approximately 1.5 $/kg) of the base case significantly exceeds current fossil-based methanol prices (0.4-0.5 $/kg) when supplied with wind-generated electrical energy at 25 $/MWh. Sensitivity analyses identified SOEC capital cost, reactor carbon conversion (which affects efficiency), target carbon intensity of MeOH production, electricity price, and plant capacity factor as the most critical economic drivers influencing MSFP. In this presentation, energetic heat balance, plant configurations, and techno-economic sensitivity analyses are provided. Comparisons are made with other green hydrogen-based MeOH production routes. Although the SOEC-based pathway leverages inherent efficiency advantages for syngas production, achieving economic competitiveness of all alternative routes will certainly benefit from reductions in electrolyzer capital costs, lifetime enhancement, lower renewable electricity prices, and carbon intensity requirements that are supported by low-carbon policies.