2025 AIChE Annual Meeting

(579d) Numerical Study of Protonic Ceramic Fuel Cells for Methane Flare Mitigation Via Power and Benzene Cogeneration

Authors

Jaden Norman - Presenter, University of Oklahoma

Abu Yousuf - Presenter, University of Oklahoma

Pejman Kazempoor - Presenter, University of Oklahoma

Chuancheng Duan, Colorado School of Mines

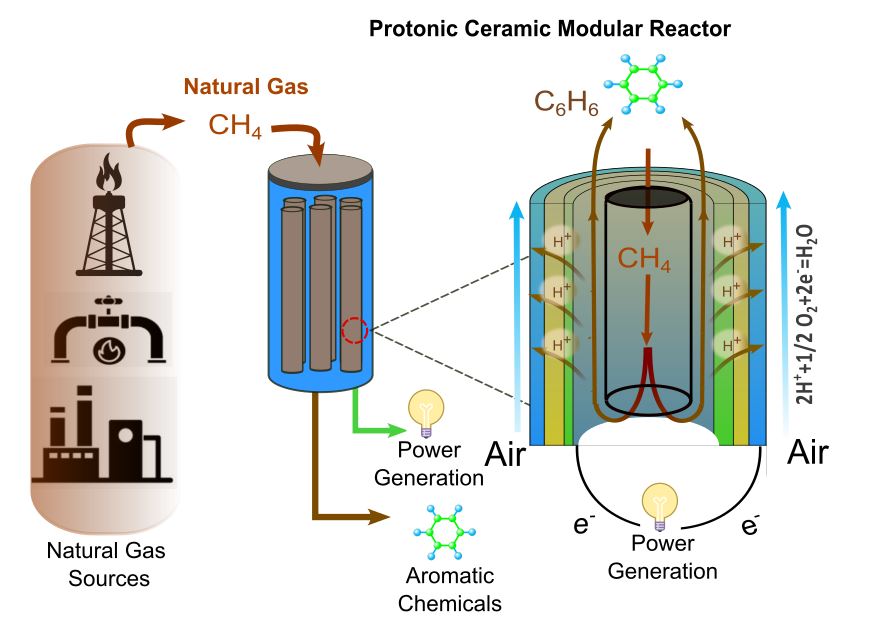

Protonic Ceramic Fuel Cells (PCFCs) offer a promising solution for mitigating methane emissions by converting flare gas into electricity, hydrogen, and value-added aromatics. Despite their potential, PCFCs face challenges such as low power density and catalyst deactivation, limiting their commercial viability. This study develops a numerical model of a methane-fed PCFC system, integrating mass/energy balances, electrochemical reactions, and methane dehydroaromatization (MDA) kinetics to assess performance. The model employs a tubular PCFC geometry and is solved using Engineering Equation Solver (EES). Results show a modest power density (~0.01 W/cm²) due to slow MDA kinetics but highlight economic potential if manufacturing costs are reduced by 65%. Additionally, the study presents a Protonic Ceramic Electrochemical Reactor (PCER) model, evaluating oxidative and non-oxidative MDA pathways for benzene production. Validated against experimental data, the model achieves 18% methane conversion and 70% benzene selectivity while accurately predicting power generation. Parametric analyses optimize temperature, pressure, and flow rates, suggesting that 90% emissions reduction and 50% aromatic selectivity are feasible under ideal conditions. Although challenges remain, this work demonstrates PCFC technology’s potential to transform waste methane into sustainable energy and chemicals, advancing hydrogen-based energy solutions.