2025 AIChE Annual Meeting

(83d) Methylammonium Lead Iodide Photovoltaic Devices Constructed on Plastic Substrates with a Flexible Back Contact Microgroove Architecture

Authors

Christina Al Tawil, The University of Texas at Austin

Nathan Balaich, The University of Texas at Austin

Brian A. Korgel, The University of Texas at Austin

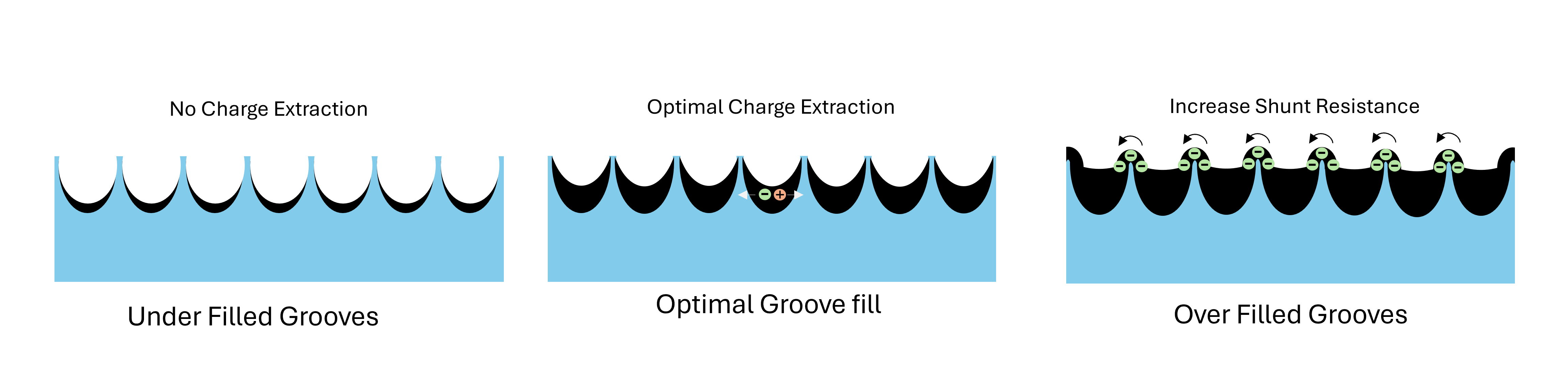

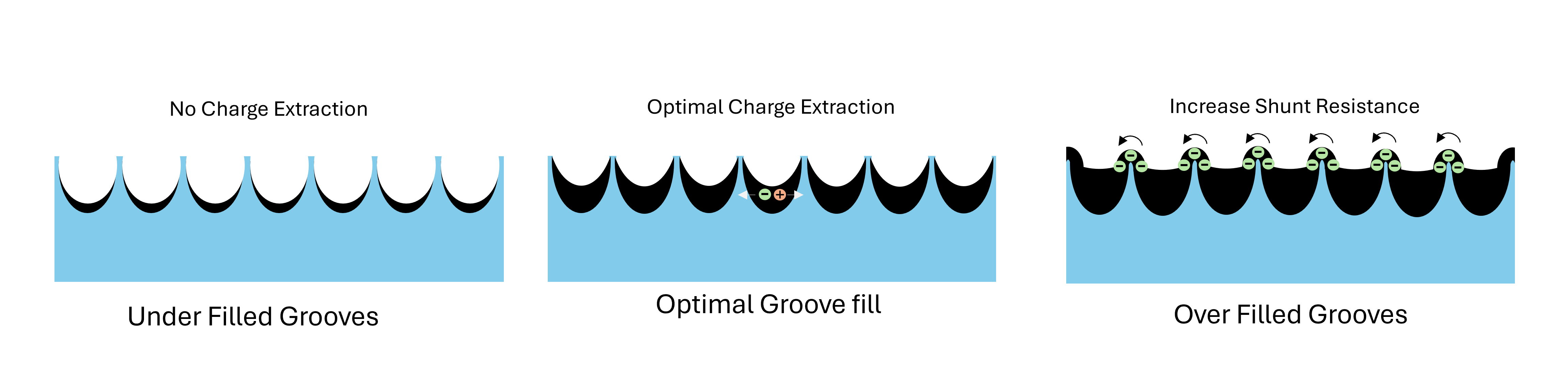

Photovoltaic devices (PVs) were fabricated using an innovative back contact architecture on plastic substrates that features a cascade of parallel microgrooves, each spanning 1.5 µm in width. This is a promising way to produce mechanically flexible PV modules using roll-to-roll manufacturing processes in which the electron and hole transport layers are added to opposing groove sidewalls by shadow deposition and the light absorbing material is deposited within the grooves by solvent or spray-based methods. Metal halide perovskites, such as methyl ammonium lead iodide ((CH3NH3)PbI3, MAPI), are particularly suitable light-absorber materials for this architecture because they can be deposited at low temperature from solvents and achieve high device efficiencies. However, MAPI and other perovskites are generally deposited from relatively toxic solvents, like dimethyl formamide (DMF). DMF is effective since it is a coordinating solvent with low volatility, but in many jurisdictions, DMF and other similar solvents cannot be used for large-scale manufacturing. This creates a challenge of finding a “greener” solvent that enables high performance, while also providing for effective groove filling. We have been exploring several solvent alternatives for MAPI deposition on plastic microgroove PV substrates using blade-coating. Processing parameters like blade height and speed were explored using DMF as a benchmark for comparison. We found that the combination of methylamine (MA) in acetonitrile can provide an effective, less toxic alternative to DMF. This is interesting since acetonitrile is relatively volatile and is a non-coordinating solvent. The promising green solvent alternative, gamma-valerolactone (GVL), which is a coordinating solvent with comparable volatility to DMF was also tested. It provided reasonable performance, similar to DMF, but MA in acetonitrile provided the highest performance of all of the solvent systems tested. Under the appropriate blade-coating conditions, it mitigates both underfilling and overfilling of grooves—as verified through scanning electron microscopy (SEM) images of cross-sectioned devices—while also providing for a high-quality absorber layer. Solvent properties play a significant role in the quality of the fabricated devices. Perovskite deposition modeled using Washburn’s equations for capillary and pore filling shows that the quality of groove filling depends on solvent viscosity, solvent surface tension, and interfacial energy, as experimentally observed. This work shows that it is possible to fabricate high performing perovskite PVs using solvents that are significantly less toxic than those typically used and reported in the literature.