2025 AIChE Annual Meeting

(631e) Integrated Process Development and Evaluation for Biomass-Derived Platform Chemicals: Economic and Environmental Assessment

This study proposes a novel, stand-alone process for the production of HMF from white birch biomass, integrating solvent self-sufficiency, multi-stream valorization, and robust environmental and economic assessment. The design focuses on maximizing biomass utilization efficiency while minimizing external resource input, thereby enhancing both cost-effectiveness and sustainability.

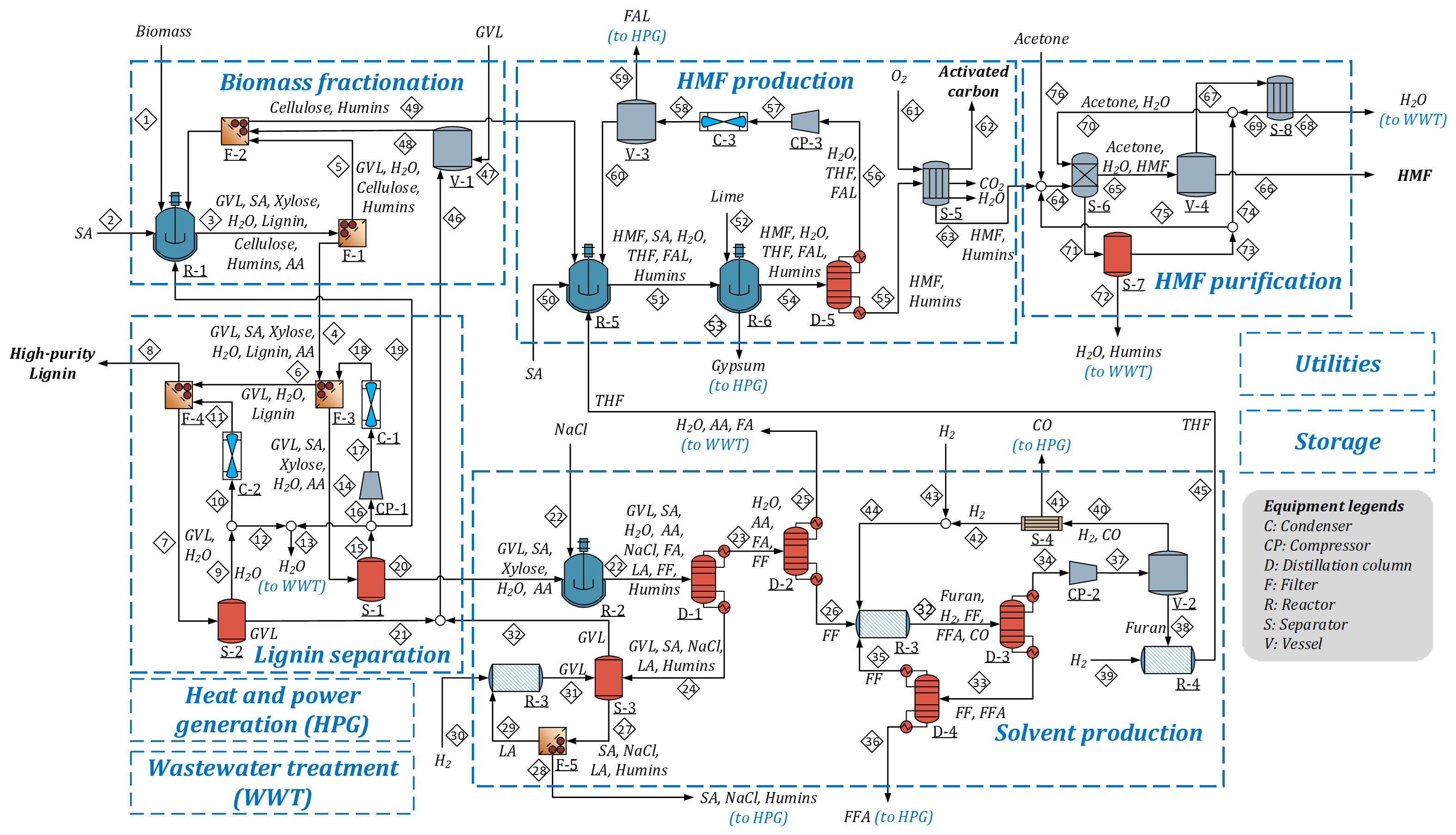

White birch was selected as the lignocellulosic feedstock owing to its balanced composition of cellulose (~40–45 wt%), hemicellulose (~25–30 wt%), and lignin (~20–25 wt%). The process initiates with a mild acid-catalyzed fractionation of the biomass using a gamma-valerolactone (GVL)/H₂O solvent mixture (mass ratio 70:30) and 0.1 M H₂SO₄ catalyst under 398 K and 3.4 atm. This reaction enables the separation of cellulose with >95% purity while converting the hemicellulose fraction into C5 sugars and dissolving the lignin into the solvent. Importantly, the integrity of all three biomass components is preserved due to the mild operating conditions, which facilitates their further valorization. The cellulose fraction is subjected to direct acid-catalyzed dehydration to HMF in a THF/H₂O solvent system (90:10 w/w) using 20 mM H₂SO₄ at 483 K and 68 atm. Under these conditions, an HMF yield of 42.0% is achieved, with the remaining carbon distributed across various byproducts including furfural (3.2%), levoglucosenone (2.0%), levulinic acid and formic acid (1.9%), glucose (1.0%), and humins (49.8%). Tetrahydrofuran (THF) is used as the solvent due to its capacity to selectively solubilize HMF while facilitating cost-effective downstream separation due to its low boiling point (339 K), compared to HMF (565 K).

To minimize external chemical dependencies, the process innovatively utilizes the hemicellulose-derived furfural as a dual-purpose stream. A defined portion of the furfural is catalytically converted to tetrahydrofuran (THF) via a two-step hydrogenation process. In the first step, furfural is selectively reduced to furan using molecular hydrogen under atmospheric pressure (1 bar) at 280°C, achieving a conversion rate of 93.1%. Subsequently, the furan intermediate undergoes complete hydrogenation to THF at 100°C under 22.5 bar H₂ pressure, with a reported 100% conversion efficiency. This sequential conversion route not only delivers high yields of THF but also offers favorable operating conditions that are well-suited for integration into a continuous processing environment. The in-situ generation of THF eliminates the need for external procurement and creates a closed-loop solvent cycle that significantly improves the autonomy and cost efficiency of the process. The surplus furfural, which is not used for THF production, is purified and sold externally, adding a high-value revenue stream to the process and reinforcing its economic viability.

Simultaneously, the lignin fraction is upgraded through biological processing into adipic acid using a bioreactor system. Adipic acid is a high-value commodity chemical widely used in the production of nylon-6,6 and plasticizers. Its incorporation into the product portfolio of this process introduces significant economic value and enhances the competitiveness of bio-based HMF production. An alternative utilization scenario is also considered, where lignin is directed to a combined heat and power (CHP) subsystem, supplying process energy through combustion in a boiler-turbine setup. This approach, while foregoing the high-value adipic acid stream, improves process energy self-sufficiency and decreases dependence on fossil-based electricity and natural gas. Humins formed during HMF production are recovered and thermally processed at 600°C in the presence of oxygen to generate activated carbon (AC), a valuable sorbent material. The conversion efficiency of carbon in humins to AC is assumed to be 57.2%, based on empirical data. This valorization not only diverts waste from disposal but also contributes to circularity and carbon storage within the process system.

Techno-economic analysis (TEA) was carried out under pioneer plant assumptions, reflecting the cost inflation and performance risk associated with first-of-a-kind commercial facilities. The scale of the process was set at 2,000 dry ton of biomass input per day, in accordance with U.S. DOE and NREL recommendations for economic viability. The analysis, conducted using Aspen Plus, Aspen Economic Analyzer, and discounted cash flow modeling, yielded a minimum selling price (MSP) of HMF at $1,374.9/ton. This figure compares favorably to conventional estimates and demonstrates that internal solvent generation and co-product integration can substantially improve process economics. Sensitivity analysis was performed to evaluate the influence of key parameters, including feedstock price, THF recovery efficiency, catalyst lifetime, lignin utilization path, and adipic acid market price. Among these, the furfural-to-THF conversion efficiency and the route of lignin valorization emerged as dominant factors affecting profitability. The results suggest that under favorable market conditions for adipic acid and furfural, the proposed process could outperform existing HMF production pathways by a significant margin.

A cradle-to-gate life-cycle assessment (LCA) was also conducted to quantify the environmental performance of the process. The functional unit was defined as the production of 1 kg of HMF. Environmental impact was assessed using the ReCiPe Midpoint (H) method within SimaPro 9.1, with background data from the EcoInvent 3.6 database. Notably, a system expansion approach was applied to allocate environmental benefits from co-products, diverging from the more conservative mass allocation used in previous studies. Under the best-case scenario—where lignin is upgraded to adipic acid and humins are converted to AC—the net global warming potential (GWP) was calculated to be −10.4 kg CO₂-eq per kg of HMF produced. This negative carbon footprint is primarily due to the displacement of fossil-based adipic acid and the carbon sequestration effect of activated carbon. The analysis further evaluated the role of electricity sourcing by comparing eight alternative power generation profiles, including natural gas, coal, hydroelectric, nuclear, wind, biomass, and industrial by-product gases. Renewable electricity sources, particularly hydro and nuclear, yielded the lowest overall GWP and fossil depletion values, while coal-based power significantly increased environmental burdens. These findings underscore the importance of integrating energy and material recovery strategies into bio-based chemical processes. Moreover, the ability to configure the process flexibly—with options for product diversification (furfural, THF, adipic acid, AC) and energy self-reliance—positions it well for commercial adaptation across diverse market conditions.

In conclusion, the process design presented in this study delivers a compelling model for sustainable HMF production. By leveraging the full potential of lignocellulosic biomass and implementing co-product valorization with internal solvent recycling, the process achieves both economic competitiveness and exceptional environmental performance. This integrated system provides a scalable, resilient, and low-carbon pathway for the development of HMF and downstream products such as FDCA and PEF, offering a meaningful step toward fossil-free polymer production and circular bioeconomy strategies.