2025 AIChE Annual Meeting

(23d) Enhancing Lipid Production in Yarrowia Lipolytica through CO2-Derived Substrate Co-Feeding and Continuous Fermentation

Authors

Elif Kurt - Presenter, Umass Lowell

Evelyn Anjo, University of Massachusetts Lowell

Dongming Xie, University of Massachusetts-Lowell

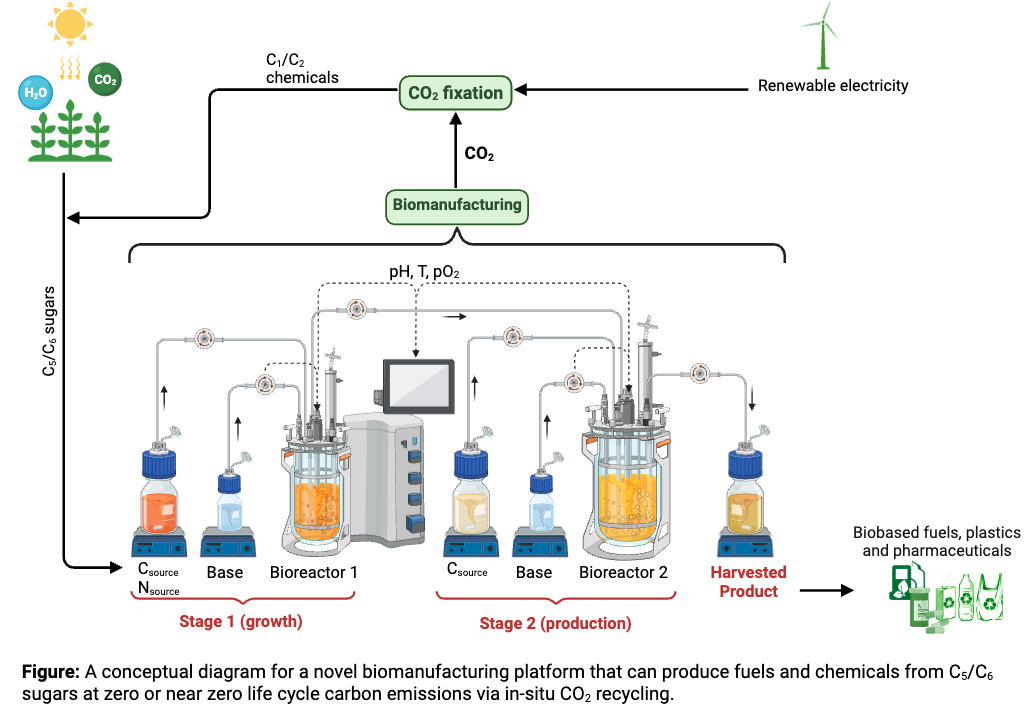

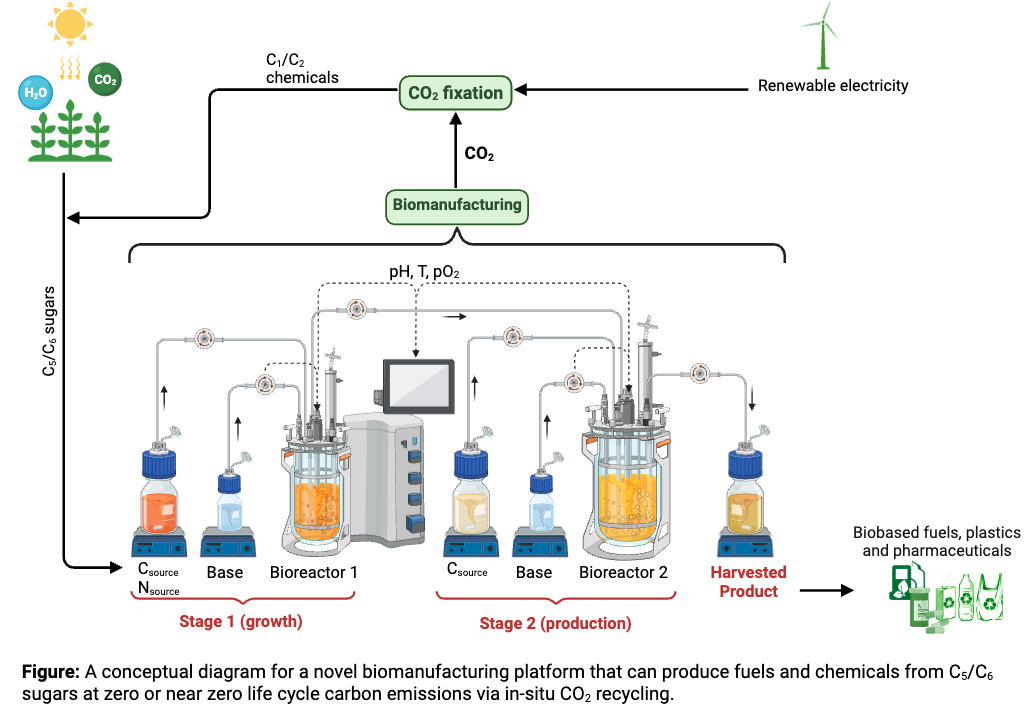

Microbial biomanufacturing offers a sustainable way for producing biofuels and high-value chemicals, yet carbon loss as CO2 during fermentation undermines yield and environmental benefits. This research introduces an innovative approach to enhance lipid production in the oleaginous yeast Yarrowia lipolytica by integrating CO2-derived C1/C2 chemicals (formate and acetate) with glucose co-feeding and optimizing continuous fermentation processes. Addressing the challenge of low lipid yields from traditional glucose-based batch fermentation, we demonstrate that co-feeding acetate with glucose reduces carbon loss by 40-50%, achieving a lipid titer of 35.6 g/L and a lipid-to-cell dry weight (CDW) ratio of 71% in fed-batch trials with the wild type and engineered Y. lipolytica. To overcome labor-intensive optimization, predictive kinetic modeling was developed, forecasting optimal single-stage continuous fermentation conditions, yielding a simulated lipid productivity of 1.832 g/L/h and biomass exceeding 113 g/L. Experimental validation in the single-stage continuous fermentation confirmed enhanced biomass (up to 120 g/L) and lipid titers, with adaptive laboratory evolution (ALE) further improving lipid/CDW to 76% in screened mutants. These advancements signify a shift toward zero-carbon-release biomanufacturing, leveraging CO2 recycling and continuous processing to boost efficiency. The methodology, grounded in metabolic engineering and process simulation, advances the state of knowledge in chemical engineering by offering a scalable, eco-friendly framework for lipid production. Ongoing work will refine two-stage continuous systems and downstream recovery, positioning this platform as a transformative solution for sustainable biofuel and chemical synthesis.