2025 AIChE Annual Meeting

(191au) Enhancing Digital Twin Development through Human-Machine Collaboration: Insights from a Pan-Coating Scale-up Case Study

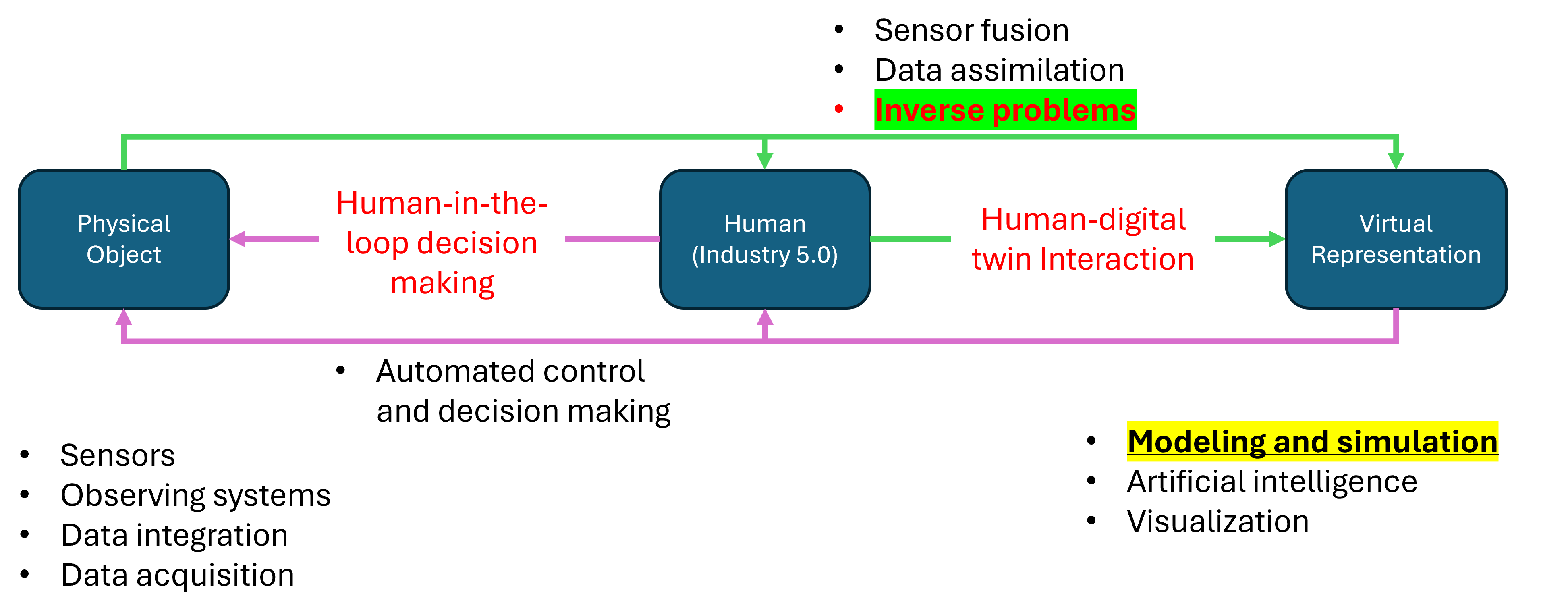

A general approach to solving inverse problems by means of digital twins is presented and demonstrated for a specific case: the scale-up of a tablet film coating process using generic coating pans. A digital twin that can function autonomously and/or with human interaction was developed. The development required rearranging the governing process equations by making Key Performance Indicators (KPIs) the input variables and replacing complex process equations with special fit-for-purpose mathematical models.

Exploring the impact of pan load revealed that, contrary to prevailing views, optimal process capacity does not necessarily occur at maximum pan load. The digital twin automatically found the optimal pan load. It is shown that the need to minimize physical experiments and better understanding the capabilities of digital twins led to improved scale-up approaches. It is also shown that the use of digital twins can significantly reduce the number of exploratory, optimization, and process-ranging experiments thereby resulting in major time and cost savings.

Our work suggests that, as the potential of digital twins becomes clearer, thinking must evolve to challenge traditional methods of process design, operation, and modification. This evolution will, in turn, lead to more effective digital twins.