Microfluidics is the study of fluid flow within structures at the sub-millimeter scale. This field has been extensively researched over the past few decades and has applications across a range of disciplines, including biology, medicine, chemistry, engineering, and environmental science

1. Microfluidic devices are typically fabricated using soft lithography, a process that involves creating polydimethylsiloxane (PDMS) structures from SU-8 molds via photolithography. While this method offers high precision and optical clarity, it requires clean-room environments and specialized equipment, making it expensive and time-consuming, especially for educational institutions without access to such facilities. As a result, developing simple and affordable non-lithographic techniques for microfluidics is essential, particularly since the costs of traditional methods create financial barriers for many K-12 schools and higher education institutions. Xurography, craft cutting, or razor writing, was introduced as a microfabrication method by Bartholomeusz et al. in 2005

2. This low-cost technique does not require cleanroom facilities or specialized staff

3. Desktop cutting plotters from companies like Silhouette and Cricut, starting at ~$200 are commonly used, and offer performance comparable to more expensive equipment

4. The materials used in xurography are also more affordable than those for soft lithography; for instance, silicon wafers typically cost $6–$20 each, while the plastics and adhesives used in xurography cost approximately $5 and $2 per square foot, respectively

5. Consequently, microdevices fabricated with Xurography are less expensive; for example, six tape-bonded microchips can be produced for under $2

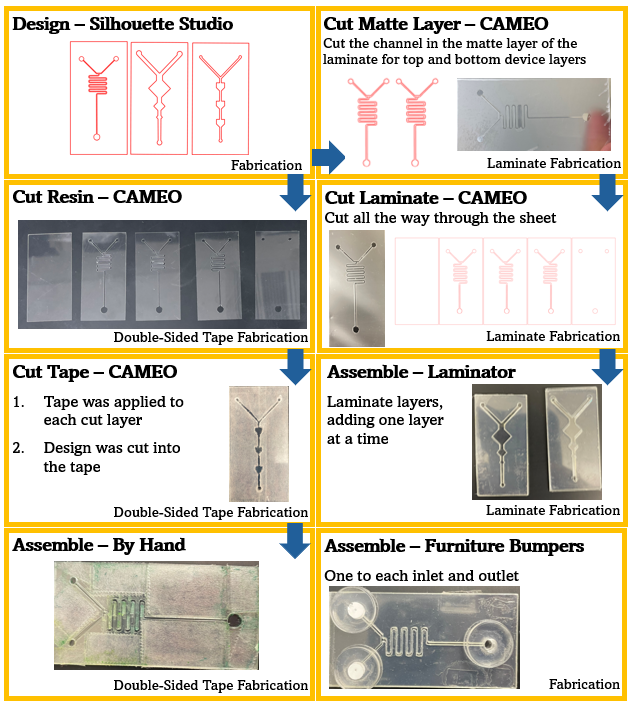

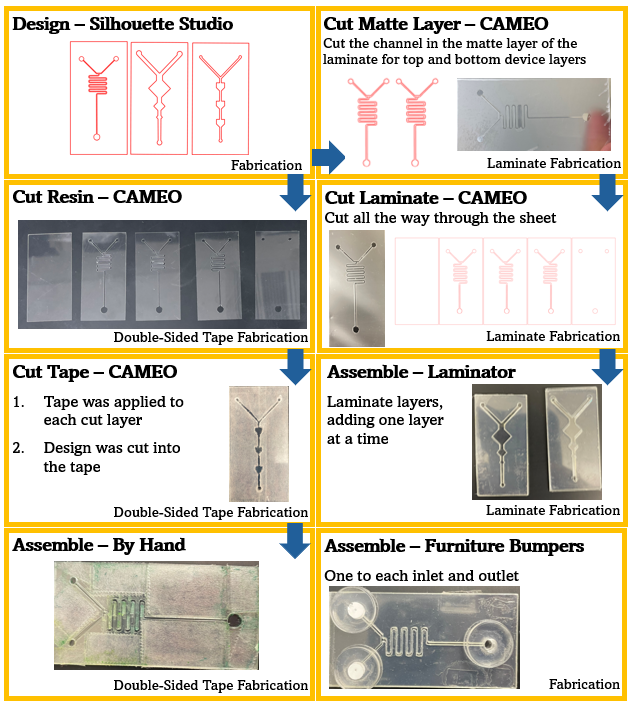

6. Attached Figure illustrates the process of creating a microfluidic device. Angular channel geometries were fabricated using laminate sheets and electrodes to study bioparticle movement under direct current. A non-uniform electric field was applied via electrodes to enable bioparticle manipulation within the microchannels. Various channel modifications, to create non-unifority in the electric field, were tested to achieve precise control over particle motion. Advances in low-cost microdevice fabrication through Xurography hold great promise for expanding research and enabling affordable electrokinetic separation of bioparticles. This innovative method can equip researchers and healthcare professionals with accessible diagnostic tools, ultimately improving public health outcomes.

References

(1) Faustino, V.; Catarino, S. O.; Lima, R.; Minas, G. Biomedical microfluidic devices by using low-cost fabrication techniques: A review. Journal of biomechanics 2016, 49 (11), 2280-2292.

(2) Bartholomeusz, D. A.; Boutte, R. W.; Andrade, J. D. Xurography: rapid prototyping of microstructures using a cutting plotter. Journal of Microelectromechanical Systems 2005, 14 (6), 1364-1374. DOI: 10.1109/JMEMS.2005.859087.

(3) Damodara, S.; Shahriari, S.; Wu, W.-I.; Rezai, P.; Hsu, H.-H.; Selvaganapathy, R. 1 - Materials and methods for microfabrication of microfluidic devices. In Microfluidic Devices for Biomedical Applications (Second Edition), Li, X., Zhou, Y. Eds.; Woodhead Publishing, 2021; pp 1-78.

(4) Martínez-López, J. I.; Betancourt, H. A.; García-López, E.; Rodriguez, C. A.; Siller, H. R. Rapid Fabrication of Disposable Micromixing Arrays Using Xurography and Laser Ablation. LID - 144. (2072-666X (Electronic)). From 2017 May.

(5) Walsh, D. I.; Kong, D. S.; Murthy, S. K.; Carr, P. A. Enabling Microfluidics: from Clean Rooms to Makerspaces. Trends in Biotechnology 2017, 35 (5), 383-392. DOI: https://doi.org/10.1016/j.tibtech.2017.01.001.

(6) Greer, J.; Sundberg, S. O.; Wittwer, C. T.; Gale, B. K. Comparison of glass etching to xurography prototyping of microfluidic channels for DNA melting analysis. Journal of Micromechanics and Microengineering 2007, 17 (12), 2407. DOI: 10.1088/0960-1317/17/12/003.