2025 AIChE Annual Meeting

(305f) Design, Modelling, and Laboratory Testing of a Multi-Tubular Reactor for Green Thermochemical Hydrogen Production

Authors

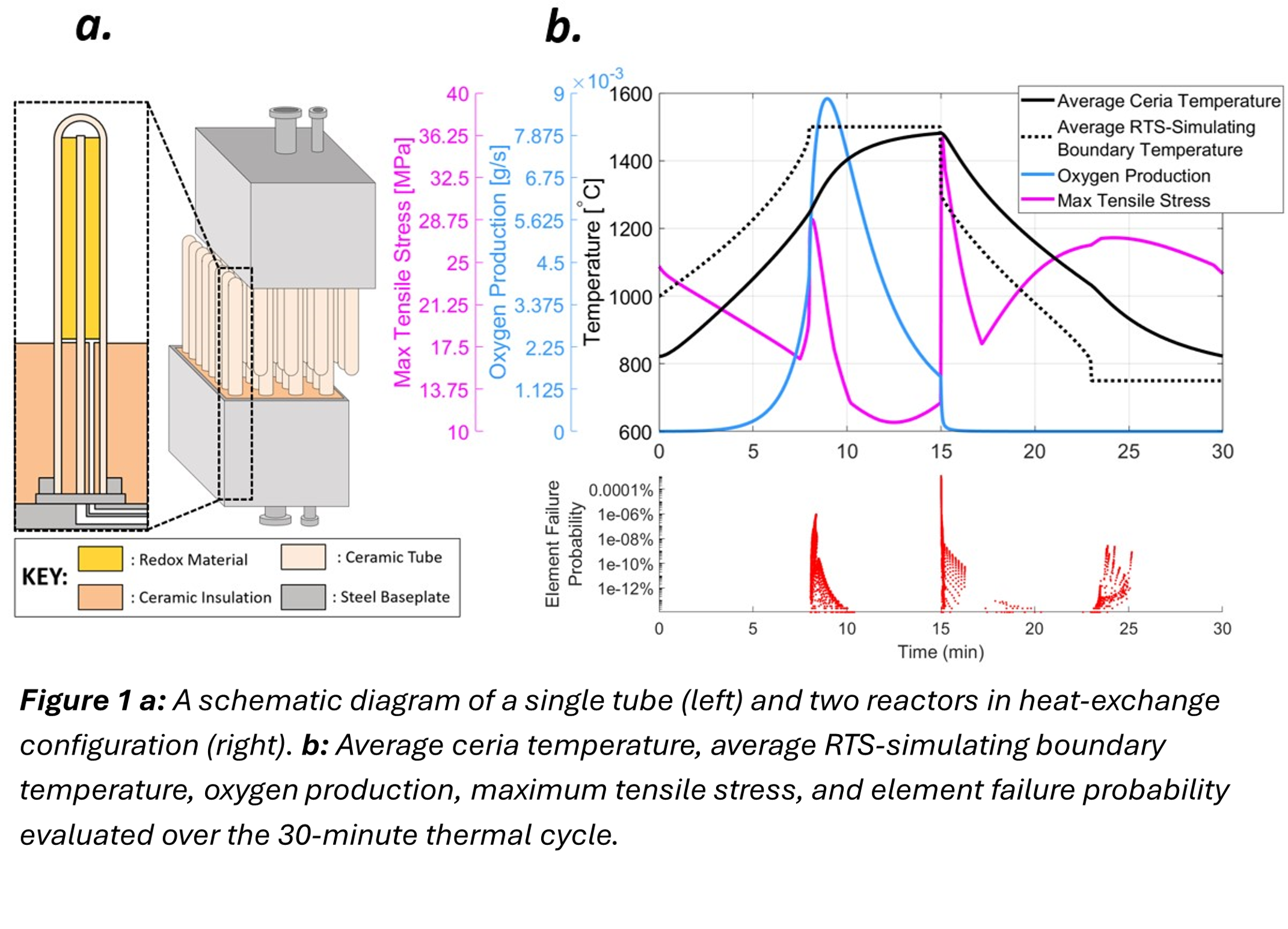

The envisioned reactor, pictured in figure 1a, features multiple rows of alumina tubes filled with redox material which intermesh with rows of heating/cooling elements or the tube rows of identical, opposing reactors during reduction/oxidation and regenerative heat transfer, respectively. Thermomechanical modeling in COMSOL Multiphysics was performed to assess key performance metrics such as productivity and efficiency and to assess the mechanical performance of the alumina tubes. We devised modeling techniques that allow us to simulate the conditions of a multi reactor RTS using only a 2D axisymmetric model of a single unit tube. The reduction reaction physics were modeled using a thermodynamic equilibrium expression as the redox material chosen for study, ceria, has fast reduction kinetics. A detailed temperature and stress dependent failure probability model was employed to gain further insight into the mechanical response of the alumina tubes to the heating/cooling cycle.

The base-case configuration, featuring 25cm exposed length of a 5cm diameter tube undergoing a 30-minute cycle, had a heat recovery effectiveness between oxidation and reduction of 60.3%, a productivity of 0.59 g/hr/tube (0.62 g/hr/kg ceria), and a heat-to-hydrogen efficiency of 12.8%. The maximum tensile stress observed in the tube was 36 MPa, corresponding to a thermomechanical failure probability of 0.17%. Figure 1b shows the temperature profiles of the ceria and the RTS-simulating boundary over the whole cycle, as well as oxygen production and maximum tensile stress in the tube. The tensile stress corresponds to element failure probability, shown at the bottom of figure 1b. We present results of parametric studies on tube diameter, tube thickness, heat recovery zone residence time, and insulation thickness, revealing design tradeoffs between efficiency, productivity, and failure probability. Some key findings are that thinner tubes are beneficial both thermally and mechanically, and that increasing the heat exchange phase time results in higher efficiency, lower productivity, and lower thermomechanical failure probability. Modeling results showed promise for the continued development of this reactor design for use in the RTS.

We also present results from early-stage testing of a single reactor tube, using a prototype reactor built around off-the-shelf components that will be subjected to thermal cycling in a 1500°C rated tube furnace. On top of running redox cycles using a stationary tube, actuators will be used to move the tube between a hot and an intermediate temperature zone to induce higher thermal stresses and de-risk the reactor for operation under simulated thermal cycling conditions. The thermochemical models will be validated using results from these benchtop-scale tests. Future work will involve building a larger prototype featuring multiple tubes, as envisioned for the final design.

References:

[1] J. T. Tran, K. J. Warren, S. A. Wilson, C. L. Muhich, C. B. Musgrave, and A. W. Weimer, “An updated review and perspective on efficient hydrogen generation via solar thermal water splitting,” WIREs Energy Environ., vol. 13, no. 4, p. e528, Jul. 2024, doi: 10.1002/wene.528.

[2] A. S. Patankar, X.-Y. Wu, W. Choi, H. L. Tuller, and A. F. Ghoniem, “A Reactor Train System for Efficient Solar Thermochemical Fuel Production,” in Volume 8B: Energy, Virtual, Online: American Society of Mechanical Engineers, Nov. 2021, p. V08BT08A024. doi: 10.1115/IMECE2021-69716.

[3] P. Scott, A. Patankar, Z. Wu, H. Haussmann, and A. Ghoniem, “High-Fidelity Thermomechanical Modeling of a Novel Indirectly Irradiated Reactor for Solar Thermochemical Fuel Production,” in ASME 2024 18th International Conference on Energy Sustainability, Anaheim, California, USA: American Society of Mechanical Engineers, Jul. 2024, p. V001T08A001. doi: 10.1115/ES2024-130505.