2023 AIChE Annual Meeting

(27h) Simulation-Based Evaluation of the Pre-Treatment of Acid Raw Materials in Biodiesel Production

Authors

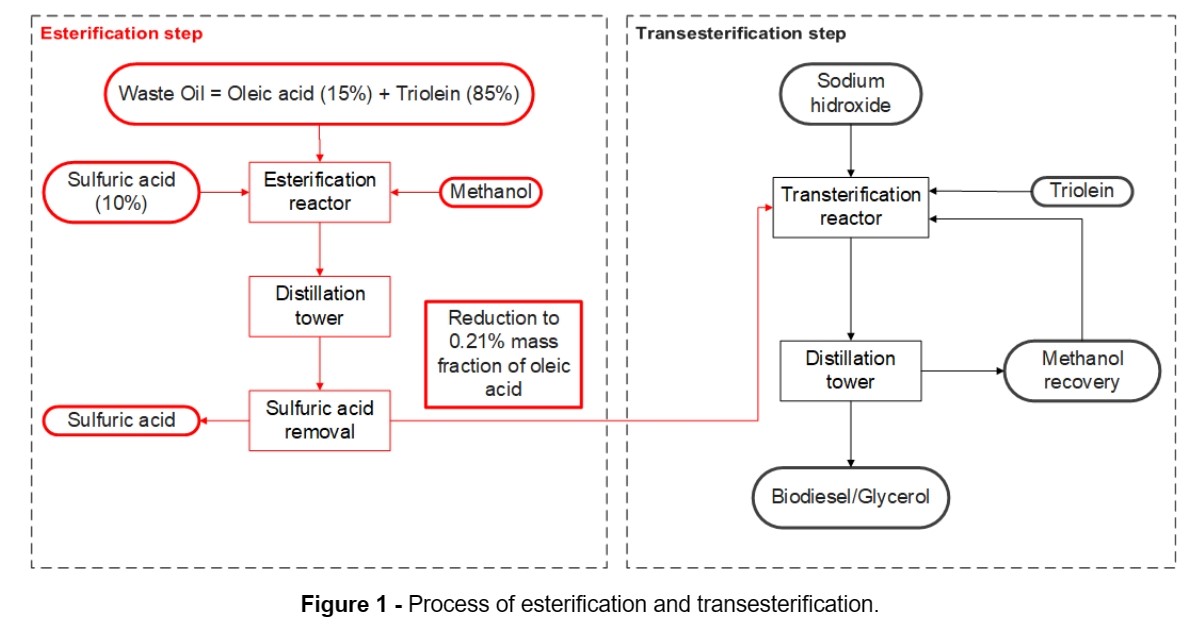

The process modeling was carried out in the AVEVA Process Simulation (APS) platform, based on the "B3 - Biodiesel Process" example3, where triolein was used to represent low acidity refined oil under alkaline homogeneous catalysis (NaOH) reacting with excess methanol. This process extends beyond the transesterification reaction, also encompassing purification, washing, and drying of biodiesel. The refined oil was included in the stream to ensure a variety and availability of locally easily produced raw materials in Brazilian urban centers, such as residual oils and fats (a byproduct of cooking vegetable oil in food, which undergoes a series of physical and chemical transformations in its composition)4. The simulation was able to convert 97.6% of the oleic acid, which corresponds to a reduction in the value of free fatty acids, indicating a reduction in the acidity of residual oils and fats per mass from 15% to 0.21%. The model results presented a satisfactory conversion of oleic acid into triolein in the pre-treatment stage to be used in the alkaline-catalyzed transesterification reactor section.

Keywords: Modeling; Simulation; Esterification; Free Fatty Acids; Biodiesel.

References

1 CIOLKOSZ, D. (2020), Whatâs so different about biodiesel fuel? Bioenergy, 739â744.

2 YANG, Y. J.; CHAI, M.; TU, Q.; LU, M. (2014) Esterification pretreatment of free fatty acid in biodiesel production, from laboratory to industry. Fuel processing technology, 125, 106-113.

3 AVEVA (2022). AVEVA Process Simulation. B3 - Biodiesel Process. Undocumented examples.

4 CARNEIRO, F. L. (2022), Modeling and simulation of biodiesel production from oil and residual fat from the city of Quixadá-CE. Available at: biblioteca.ifce.edu.br/index.asp?codigo_sophia=105952.