2025 AIChE Annual Meeting

(430h) Water-Based Drilling Fluid Containing ZIF-8@Graphene Composite for Effective Hydrogen Sulfide Scavenging

Authors

Metal–organic frameworks (MOFs) have emerged as promising H₂S scavengers due to their high surface area and tunable surface chemistry. In particular, zeolitic imidazolate frameworks (ZIFs) offer abundant metal site and nitrogen-rich linkers that can bind or react with H₂S [4]. Recent work demonstrated that adding 1 wt% ZIF-8 nanoparticles to a WBM prolonged H₂S breakthrough time dramatically while also enhancing the mud’s rheological profile (increasing plastic and apparent viscosity, yield point, and gel strength) without compromising fluid loss control . Such findings highlight MOFs’ potential as dual-function drilling fluid additives [1]. However, MOF particles in isolation may agglomerate or be difficult to disperse in the drilling fluid. To address this, we explore graphene-supported MOF composite (i.e., graphene@ZIF-8), leveraging graphene’s high surface area and stability to anchor MOF crystals. Graphene-based nanomaterials are known to improve drilling fluid rheology and filtration traits , and prior studies have successfully synthesized MOF/graphene hybrids [5]. However, to the best of our knowledge, there is no published study to date that reports the inclusion of any material comprising MOF and graphene in drilling fluids while examining its H₂S scavenging performance. Accordingly, the key motivation of this study is to synthesize a ZIF-8@graphene composite, formulate a water-based drilling fluid containing this composite, and investigate its H₂S scavenging performance and fluid flow behavior.

Graphene@ZIF-8 was synthesized via an in-situ growth method adapted from literature [6] . In a typical procedure, Zn(NO₃)₂·6H₂O is dissolved in water and mixed with graphene. After graphene dispersion (using stirring and ultrasonication), an organic linker solution (2-methylimidazole in concentrated ammonia) is rapidly added under stirring. The MOF crystallization is allowed to proceed for ~1 h, forming ZIF-8 frameworks nucleated on the graphene sheets. The composite particles are recovered by repeated centrifugation/washing and dried to yield a fine powder of graphene@ZIF-8. This synthesis yields nano- to microscale ZIF crystals anchored on conductive graphene networks.

A baseline WBM was prepared with 4–5% w/v bentonite in water and typical additives (polymeric viscosifier and starch-based fluid loss reducer, with KOH for pH control) [1] . To test the impact of ZIF-8@graphene on H₂S scavenging and fluid flow behavior, a mud formulation containing 0.25 wt.% of this composite was prepared by dispersing it into the base mud. The mixture was stirred vigorously to ensure uniform distribution of the composite particles in the drilling fluid. For comparison, the base fluid without the addition of the ZIF-8@graphene composite was also tested. For each formulation, the H₂S scavenging performance was evaluated using a dynamic absorption test where H₂S gas was continuously bubbled through a mud sample in a sealed cell, and the outlet gas was monitored in real-time with an H₂S detector. The total H₂S uptake was estimated from the integrated H₂S flow [1]. Additionally, the shear stress-shear rate test was conducted using standard API rheological measurements .

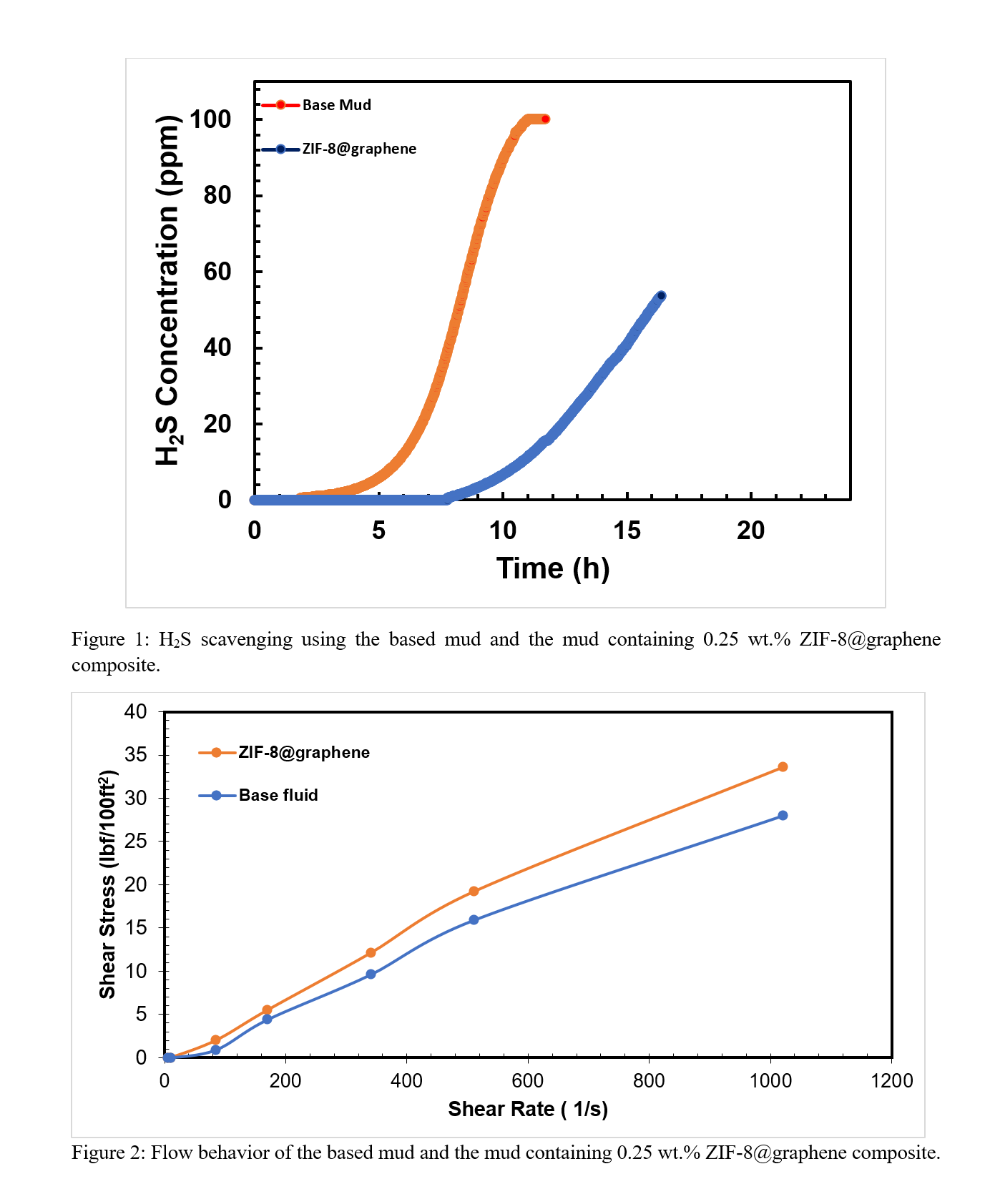

As shown in Figure 1, ZIF-8@graphene composite greatly outperformed the base mud in H₂S capture. The ZIF-8@graphene additive extended the H₂S breakthrough time substantially; no H₂S was detected in the gas outlet up to 7.5 h. This indicates a higher H₂S scavenging capacity for the WBM containing the composite. Quantitatively, the H₂S amount captured by the ZIF-8@graphene mud is about 5 times greater than that of base mud. This finding is consistent with the stronger affinity of ZIFs for H₂S reported in literature [1] . The graphene support did not hinder gas uptake; instead, its likely improved particle dispersion, allowing better utilization of active sites [7].

In terms of fluid flow behavior, the incorporation of ZIF-8@graphene did not significantly alter the shear stress-shear rate data, indicating minimal impact on the mud rheology, and, thus, fluid flow (see Figure 2). The non-Newtonian flow behavior shown in Figure 2 is typical for drilling fluids. No signs of severe flocculation or gelation were observed – the muds remained pumpable and stable. These findings align with prior studies where nanoparticle additives did not significantly alter drilling fluid viscosity and gel structure [3,5] .

This research provides strong experimental evidence that ZIF-8@graphene composite significantly enhance H₂S scavenging performance in water-based drilling fluids, with superior capacity and longer breakthrough time. Additionally, the shear stress-shear rate result suggest that the composite maintained key rheological properties, indicating its dual functionality as an H₂S scavenger and rheology maintainer/enhancer. These findings are significant as they introduce ZIF-8@graphene composite as novel, multifunctional additive to drilling fluid design and demonstrate, for the first time, the practical integration of MOF/graphene hybrids in this application. This work advances the current state of knowledge by bridging materials science and drilling engineering, paving the way for more efficient, safer, and environmentally friendly drilling operations.

References

[1] M. Iddrisu and S. A. Onaizi, “H2S scavenging performance and rheological properties of water-based drilling fluids comprising ZIF-67,” Geoenergy Science and Engineering, vol. 228, p. 212007, Jun. 2023, doi: 10.1016/j.geoen.2023.212007.

[2] A. Ahmed, S. A. Onaizi, and S. Elkatatny, “Improvement of hydrogen sulfide scavenging via the addition of monoethanolamine to Water-Based drilling fluids,” ACS Omega, vol. 7, no. 32, pp. 28361–28368, Aug. 2022, doi: 10.1021/acsomega.2c02890.

[3] S. A. Onaizi, M. A. Gawish, M. Murtaza, I. Gomaa, Z. Tariq, and M. Mahmoud, “H2S scavenging capacity and rheological properties of Water-Based Drilling muds,” ACS Omega, vol. 5, no. 47, pp. 30729–30739, Nov. 2020, doi: 10.1021/acsomega.0c04953.

[4] M. Iddrisu et al., “Harnessing zeolitic imidazolate framework-8 (ZIF-8) nanoparticles for enhancing H2S scavenging capacity of waste vegetable oil-based drilling fluids,” Emergent Materials, vol. 7, no. 2, pp. 591–602, Aug. 2023, doi: 10.1007/s42247-023-00535-7.

[5] A. H. Arain, S. Ridha, S. U. Ilyas, M. E. Mohyaldinn, and R. R. Suppiah, “Evaluating the influence of graphene nanoplatelets on the performance of invert emulsion drilling fluid in high-temperature wells,” Journal of Petroleum Exploration and Production Technology, vol. 12, no. 9, pp. 2467–2491, Apr. 2022, doi: 10.1007/s13202-022-01501-5.

[6] W. Sun, X. Zhai, and L. Zhao, “Synthesis of ZIF-8 and ZIF-67 nanocrystals with well-controllable size distribution through reverse microemulsions,” Chemical Engineering Journal, vol. 289, pp. 59–64, Dec. 2015, doi: 10.1016/j.cej.2015.12.076.

[7] W. Cao et al., “Synthesis of zeolitic imidazolate framework-67 nanocube wrapped by graphene oxide and its application for supercapacitors,” Journal of Solid State Electrochemistry, vol. 23, no. 1, pp. 325–334, Nov. 2018, doi: 10.1007/s10008-018-4138-1.