2025 AIChE Annual Meeting

(418a) Valorization of Millet Agro-Residues through Pyrolysis for Biochar Production: A Sustainable Solution for Circular Agriculture

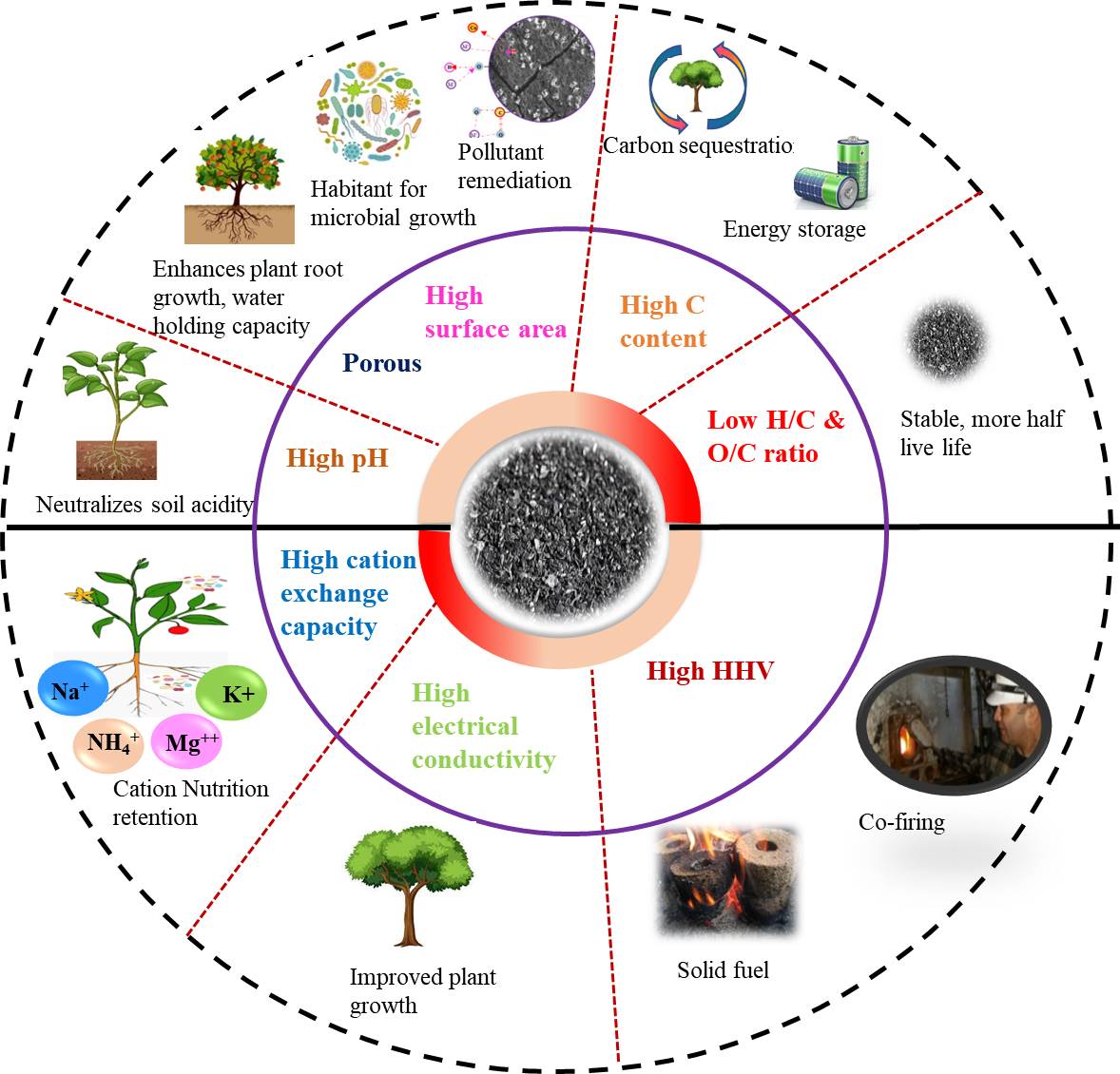

The results of the study reveal that pyrolysis temperature plays a pivotal role in influencing both the yield and the properties of biochar for both SMS and PMS. As the pyrolysis temperature increased, biochar yield decreased for both feedstocks. Specifically, the biochar yield for SMS decreased from 53% to 29%, while for PMS, it decreased from 49% to 21% as the pyrolysis temperature increased from 300°C to 600°C. Despite the reduction in yield, biochar produced at higher temperatures exhibited enhanced physicochemical properties, including a significantly higher fixed carbon content. The fixed carbon content of biochar produced at 600°C was found to be 71.58% for SMS and 75.34% for PMS, indicating the potential of these high-temperature biochars for carbon sequestration. Moreover, both biochars exhibited carbon proportions exceeding 75%, further enhancing their suitability for long-term carbon storage.

Another important finding from this study is the increase in the alkalinity of the biochar as pyrolysis temperature rose. The pH values of biochar produced from SMS and PMS at 600°C were 10.78 and 11.26, respectively. The elevated alkalinity of high-temperature biochar suggests its potential to neutralize soil acidity, making it a valuable soil amendment, especially in acidic soils. This finding aligns with the growing interest in biochar as a tool for improving soil quality in sustainable agriculture. Additionally, the biochar produced at elevated temperatures showed a reduction in the O/C and H/C ratios, indicative of increased carbon stability. These changes in the elemental composition of biochar result in a more stable product with a longer half-life, which is a desirable characteristic for long-term carbon sequestration.

Further characterization of the biochar showed that it had significant improvements in surface area and porosity when produced at higher temperatures. The surface area of biochar derived from SMS at 600°C was measured at 224.56 m²/g, and the porosity was found to be 63.86%. These characteristics are vital for applications that require the adsorption of nutrients or contaminants, such as wastewater treatment. The high surface area and porosity suggest that biochar from SMS and PMS produced at higher pyrolysis temperatures can be effective as adsorbents for organic and inorganic contaminants in wastewater. Additionally, the biochar’s porous structure can provide a habitat for soil microorganisms, thereby contributing to soil health.

The study also highlighted the properties of biochar produced at lower pyrolysis temperatures (e.g., 300°C). While the yield was higher at this temperature, the biochar produced exhibited a high cation exchange capacity (CEC), which is a crucial property for nutrient retention and soil fertility enhancement. This makes biochar from lower-temperature pyrolysis ideal for applications where nutrient retention is a priority, such as in soil amendment for improving crop yields.

In conclusion, this study underscores the potential of biochar derived from SMS and PMS as a sustainable and versatile resource with numerous applications in agriculture and environmental management. The results indicate that biochar produced from these agro-residues can serve as an effective soil amendment, improve soil health, and aid in carbon sequestration. High-temperature biochar, with its increased carbon content, stability, and surface area, offers significant promise for environmental applications such as wastewater treatment and carbon capture. On the other hand, low-temperature biochar, with its high cation exchange capacity, provides valuable potential for enhancing soil fertility and nutrient retention. This research demonstrates that both SMS and PMS are promising feedstocks for biochar production, contributing to sustainable agriculture and waste management practices.

In future work, the integration of these biochars into real-world agricultural systems and further optimization of the pyrolysis conditions, particularly the heating rate and residence time, can help to refine biochar properties for specific applications. The results presented in this study pave the way for utilizing millet agro-residues as a renewable resource for biochar production, promoting circular economy practices and contributing to environmental sustainability.