2025 AIChE Annual Meeting

(77e) Use of Co-Solvent on the Financial Viability Ofbio-Crude Production By HTL.

Authors

This innovation made it possible to obtain the first patent in the Department of Chemical Engineering and the second international patent in the Faculty of Engineering of the University of Antioquia, obtained from the hand of Cementos Argos in the United States "SOLVOTHERMAL LIQUEFACTION PROCESS FROM BIOMASS FOR BIOCRUDE PRODUCTION US 11,814,586 B2" [2] This patent establishes not only the technical but also the financial and environmental conditions that minimize production costs in obtaining a biocrude with estimated production costs of 45 – 50 USD/BBL, with characteristics similar to crude oil, from renewable sources such as biomass.

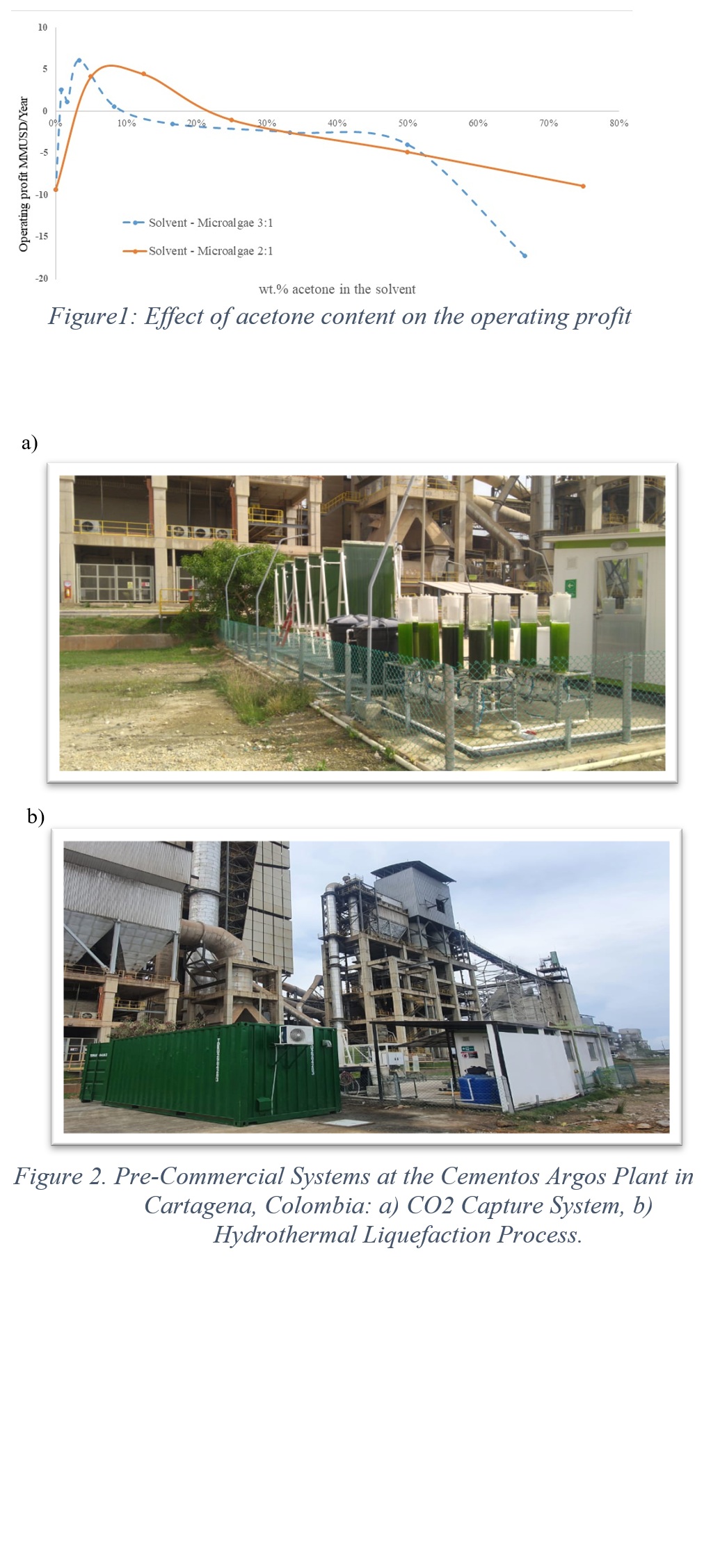

Cementos Argos, the main cement company in Colombia and fourth in Latin America, has a pilot plant for the production of microalgae from the real gases of cement production, at the Cement Plant in Cartagena Colombia, like strategy to reduce the environmental impact, interested in valuing the microalgae obtained in the capture of CO2, associated with the Ministry of Science and Technology in Colombia (MinCiencias), supported the construction of a pre-commercial hydrothermal liquefaction system near microalgae pilot plant shown in Figure 2, which seeks the production of biocrude oil in sufficient quantities for its incorporation into conventional refining systems by the hand of the oil refining, production and exploration company in Colombia Ecopetrol through the Colombian Petroleum Institute.

This development aims to establish the technical, financial and environmental conditions that allow the incorporation of biocrudes in conventional refining systems based on hydrothermal liquefaction technology, initially validated with microalgae, however it does not limit its scope only to microalgae since forest and agro-industrial waste, municipal waste residual among others could be valorized.

[1] D. Ocampo, L. A. Ríos, G. J. Vargas, and A. G. Elkin, “Effects of the use of acetone as co-solvent on the financial viability of bio-crude production by hydrothermal liquefaction of CO 2 captured by microalgae,” J. CO2 Util., vol. 89, no. 52, pp. 0–6, 2024, doi: 10.1016/j.jcou.2024.102960.

[2] D. Ocampo, L. A. Rios, E. Gómez, and G. J. Vargas, “Solvothermal Liquefaction Process For Producing Bio-Crude From Biomass,” US011814586B2, 2023.