2025 AIChE Annual Meeting

(101b) Understanding the PET Product and Recycling Supply Chains and Integrating PET Recycling Technologies for Improved Material Circularity

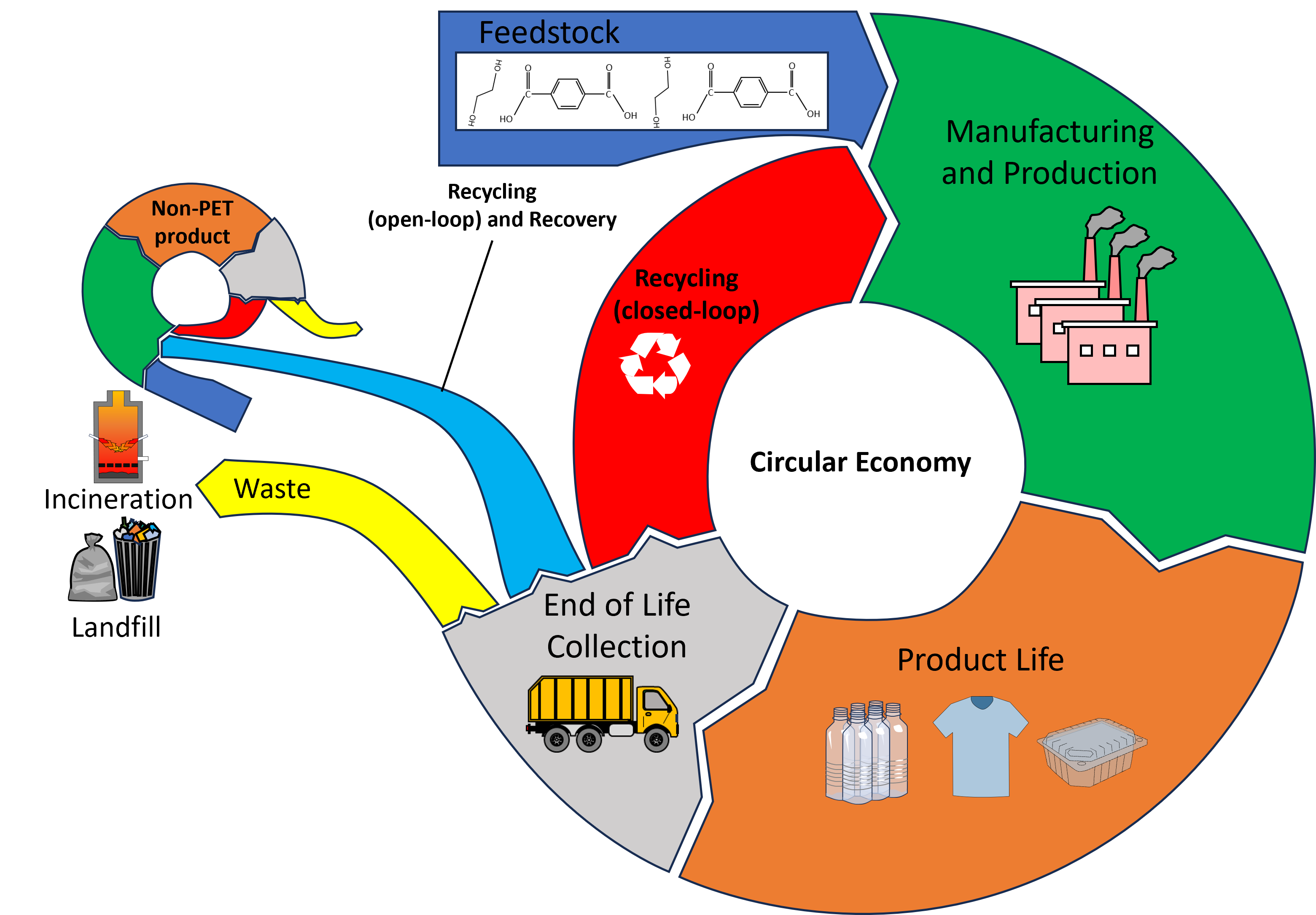

In order to understand the best path forward for the development of PET recycling technologies and improvement of PET circularity, a detailed understanding is required of PET products and compositional characteristics and how they influence the characteristics and composition of PET waste. This needs to compliment an understanding of the technological nuances of PET recycling technologies that lead to processing and reliability limitations and provide fundamental advantages and disadvantages. The purpose of this work is to tie together the information of compositional variation in PET waste feedstocks and understanding of the recycling technologies to determine processing advantages or limitations of the different technologies.

We use our analysis of PET products, the PET supply chain, and recycling technologies to describe the fundamental differences, limitations, and capabilities of both mechanical recycling and chemical recycling to inform ways to improve waste collections and design for circularity. Our conclusion is that both mechanical and chemical recycling can be used together to improve circularity and reduce resource consumption associated with PET production. Mechanical recycling technologies are the most efficient way to recycle PET and should be used to the broadest extent possible. The challenge is the purification limits of mechanical recycling limit scope of application producing high quality recycled bottles to clear bottle waste. Improved and streamlined collection of bottle waste and more homogenous bottles designs are the best way to maximize utilization of low energy demand of mechanical recycling technologies.

Chemical recycling, particularly hydrolysis and methanolysis technologies, offers a clear method to expand the scope of recoverable PET waste. While more complex and energy intensive than mechanical recycling, chemical recycling routes have much lower associated GHG potential compared to virgin PET production and meet the objective of reducing the consumption of non-renewable fossil-fuel derived feedstock. Chemical recycling offers a closed-loop recycling pathway most suited for low-quality PET wastes. We recommend the use of chemical recycling for these applications as opposed to mechanical recycling to produce open-loop downcycled products. The strongest argument for the development of chemical recycling technologies is to meaningfully expand the scope of recycling materials towards textiles, which represent ~60% of PET end use. Primary hurdles include the development of a consistent and reliable supply chain for the collection of textile waste that can allow continuous chemical textile recycling processes to operate and feedback between the material quality and composition of textile waste in the supply chain and tailored design of chemical recycling to textiles wastes.