2025 AIChE Annual Meeting

(348c) Ultra-Low Temperature Microwave-Assisted Catalytic Upcycling of Polyolefin Waste into Light Olefins

Authors

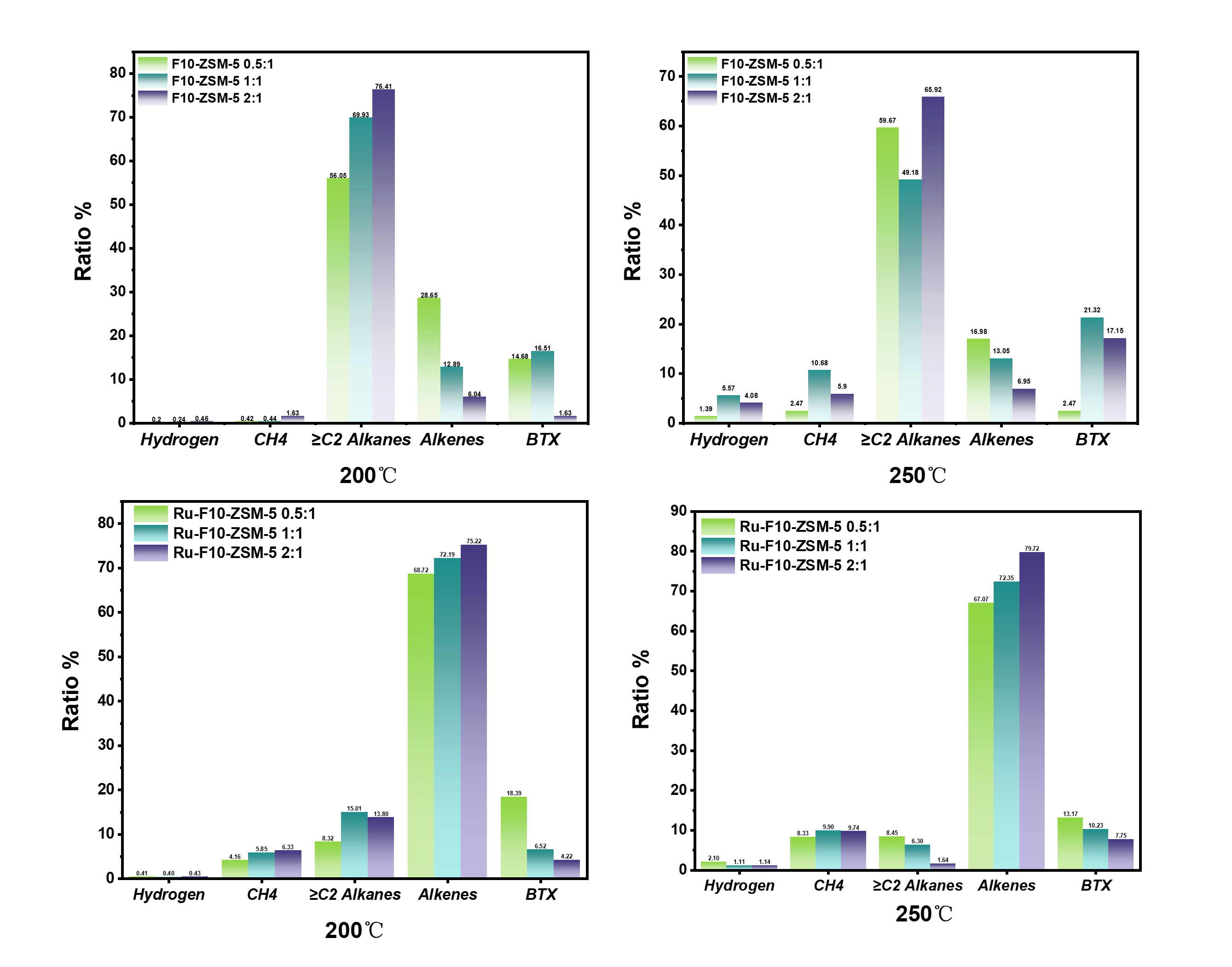

Under optimized microwave conditions at 200 °C, the catalyst achieves >85% gas production in plastic depolymerization and >75% selectivity toward light olefins, primarily ethylene and propylene. This represents one of the lowest reported operating temperatures for effective polyolefins upcycling and highlights the potential of this approach as a breakthrough in the field.

The catalyst demonstrates excellent thermal stability, recyclability, and resistance to contaminant deactivation across multiple cycles. Compared to conventional high-temperature processes, the proposed MACU strategy offers a highly energy-efficient, scalable, and industrially viable pathway for converting polyolefins waste into valuable chemical feedstocks— advancing sustainable materials management and promoting a circular plastic economy.