2025 AIChE Annual Meeting

(339b) Techno-Economic Analysis of 5 % Rice Straw Co-Firing in a Coal-Fired Power Plant Considering the Generation Efficiency Loss

Authors

However, some studies have reported a loss in the generation efficiency of the coal-fired power plant due to slagging, fouling and hot corrosion of the boiler sections [4]. It is due to the presence of alkali, alkaline earth metals and chlorine content in agro-waste residues. Slagging refers to the deposition of fused or partially fused particles on the furnace walls, whereas fouling refers to the accumulation of ash and soot particles on the convective heat transfer surfaces of the boiler. The presence of chlorine leads to the formation of compounds that lead to corrosion at elevated temperatures in the boiler. All these issues result in lowering the heat transfer efficiency as well as the life of the boiler and its accessories due to corrosion.

Aim: In this work, the effect of loss in the generation efficiency due to biomass co-firing on the levelized cost of electricity for three cases is presented. The business-as-usual (BAU) case is the first case, where no maintenance is considered for the entire plant life. In the second case, the maintenance and cleaning is done every 5th year of the plant operation. In the third case, there will be no maintenance however, but the damaged parts of the boiler are replaced once in the plant's life.

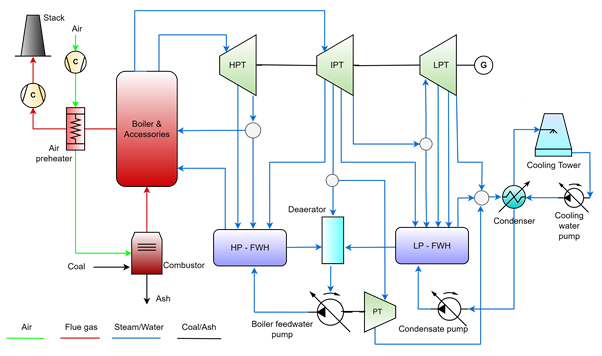

Methodology: An existing 660 MWe supercritical coal-fired power plant operating on high ash Indian coal (HHV = 15.83 MJ/kg), located at NTPC Sipat, Chhattisgarh, India is taken as a base power plant for the study [5]. The plant has inlet steam parameters of 242.2 bar/537 °C/565 °C with single-stage reheating and three-stage expansion in the turbine. Boiler accessories like air preheater and economiser improve the energy efficiency of the plant. Also, four low-pressure feed water heaters (LP-FWH) and three high-pressure feed water heaters (HP-FWH) are incorporated to enhance the regeneration efficiency. Figure 1 shows the schematics of the base power plant. Rice straw is selected as the biomass fuel (HHV = 14.7) for co-firing, as India is one of the major producers of rice, providing sufficient residue across the country.

A detailed process model for the base power plant to employ biomass co-firing is developed and validated using Aspen PlusTM as a tool. The principle of mass balance and energy balance is applied across each block, considering them as a control volume. The enthalpy and density of coal, biomass and ash are calculated using HCOALGEN and DCOALIGT property methods. The STEAMNBS and PR-BM (Peng-Robinson equation of state with Boston-Mathias modification) property methods are incorporated to evaluate the various thermodynamic properties of steam and flue gases, respectively.

The loss in generation efficiency is attributed to the heat losses in different boiler sections like superheater, reheater, economiser and air preheater due to slagging and fouling. It is assumed that 0.5 % or 1 % of loss in generation efficiency is attained at the end of plant life. The fuel feed rate is kept constant and the net power generated in presented. The effect of loss in generation efficiency is analyzed and a techno-economic analysis for the different cases is presented.

Results: The preliminary analysis shows that the levelized cost of electricity increases with increasing loss in generation efficiency. Also, a small increase of 3 °C to 6 °C is experienced in the temperature of flue gas at the stack, slightly increasing the auxiliary power consumption. A 2% increase in the levelized cost of electricity is observed for the first case (BAU) at 4.065 INR/kWh and 4.149 INR/kWh corresponding to 0.5% and 1% loss in the generation efficiency. The effect of loss in generation efficiency due to biomass co-firing is anticipated to increase with increasing the co-firing ratio. An annual reduction of 0.198 million tonnes of CO2 is observed at a CO2 avoidance cost of 1013.26 INR/tonnes of CO2 with 5 % rice straw co-firing in the coal fired power plant.

References:

[1] Khorshidi, Z., Ho, M.T. and Wiley, D.E. “The impact of biomass quality and quantity on the performance and economics of co-firing plants with and without CO2 capture”. Int J of Greenh Gas Control, 2014, 21, pp.191-202.

[2] “India's Stand at COP-26”, Press Bureau of India, Ministry of Environment, Forest and Climate Change; Government of India, 2022 https://pib.gov.in/PressReleasePage.aspx?PRID=1795071 (accessed March 12, 2025).

[3] “Revision of Rate of Central Financial Assistance (CFA) for Biomass Pellet manufacturing units under Biomass Programme component of “National Bioenergy Programme” Press Bureau of India, Ministry of New and Renewable Energy, Government of India, 2024. https://pib.gov.in/PressReleseDetailm.aspx?PRID=2035112®=3&lang=1 (accessed April 5, 2025).

[4] Zhang, Y. L., Liu , L. C., Kang , J. N., Peng, S., Mi, Z., Liao, H., Wei, Y. M.,“Economic feasibility assessment of coal-biomass co-firing power generation technology,” Energy, vol. 296, no. March, p. 131092, 2024, doi: 10.1016/j.energy.2024.131092.

[5] K. S. R. and A. K. K. V. J. J. Suresh, “3-E analysis of advanced power plants based on high ash coal,” Int. J. Energy Res., vol. 34, pp. 716–735, 2009.