2025 AIChE Annual Meeting

(402l) Target-Oriented Ccu Process Modeling: Bridging Zero Emissions and Economic Viability

Two CCU-based case studies are explored to test this approach. The first investigates the production of e-methanol (e-MeOH) through Direct Air Capture (DAC) integrated with either direct CO₂ hydrogenation or hydrothermal co-electrolysis. The second case focuses on the production of synthetic liquid hydrocarbons, specifically e-diesel and e-kerosene, via Fischer–Tropsch (FT) synthesis fed by a direct mixture of captured CO₂ and green hydrogen—without intermediate syngas formation. In this pathway, reverse water–gas shift (RWGS) reactions are used to generate the required CO, enabling direct conversion in FT reactors under high temperature and pressure.

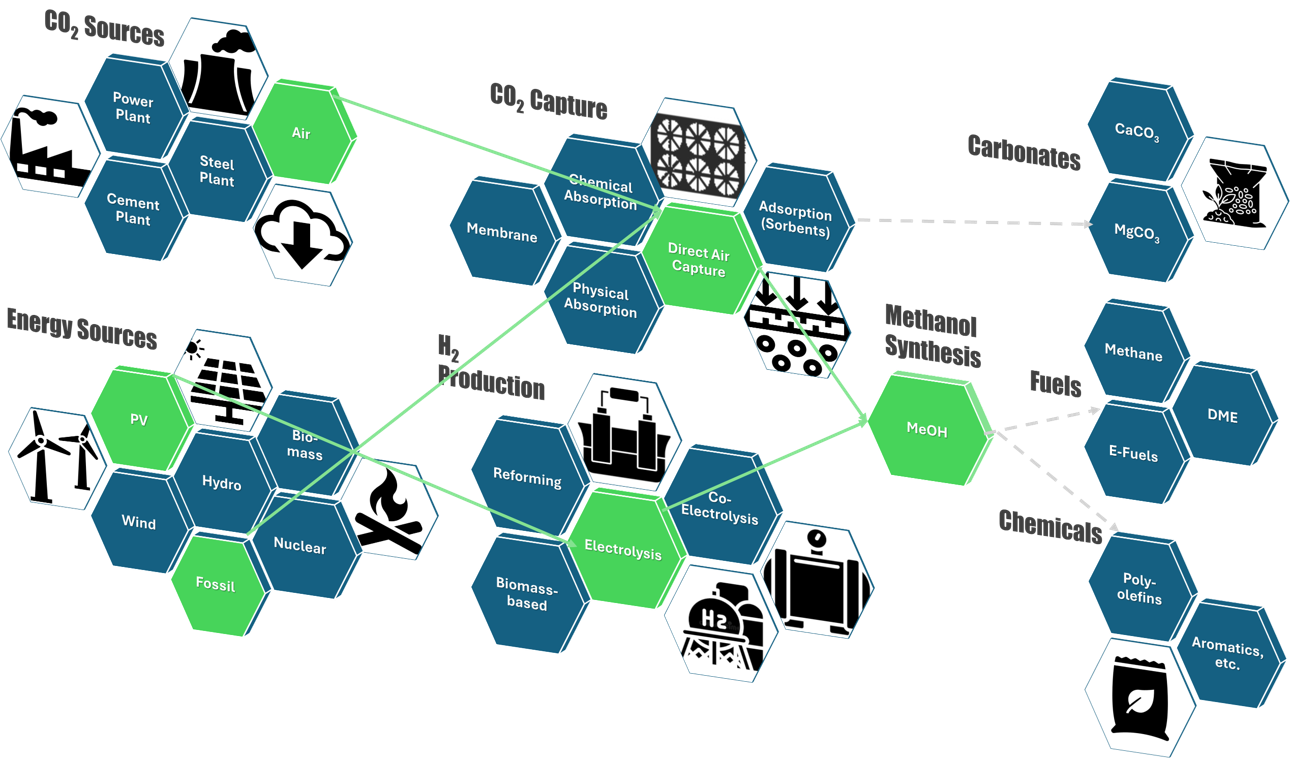

A conceptual overview of the CCU system architecture underpinning these two cases is shown in Figure 1. This framework maps key components of the carbon utilization value chain—ranging from CO₂ sources, capture methods, and hydrogen production options, to downstream synthesis routes such as methanol and e-fuel production. It also incorporates diverse energy sources that define the carbon intensity and regional viability of each configuration. The figure serves as a unifying platform for understanding how these elements interact and influence process integration potential.

For each system, detailed process models were developed in Aspen Plus V12, including DAC, hydrogen production (electrolysis, co-electrolysis), synthesis, and heat recovery. A life cycle inventory was constructed based on simulation outputs and standardized background emission data. The assessment follows a cradle-to-gate perspective in line with ISO 14040/14044 methodology.

Among the two e-MeOH routes, the hydrothermal co-electrolysis configuration demonstrates superior environmental and energy performance. This is attributed to more favorable heat integration and reduced external energy demand. In the FT system, while heat requirements are higher, notable emission reductions compared to conventional fuel refining are observed. Regional analysis indicates that grid carbon intensity has a strong influence on net system emissions, with low-carbon regions offering substantial advantages.

Techno-economic considerations include energy input per ton of product, electrolyzer loads, and process integration benefits. Internal reuse of byproducts—such as methanol for calcination and oxygen for combustion—offers additional efficiencies. These trade-offs between system complexity and carbon neutrality are analyzed to inform cost-competitive CCU deployment strategies.

The novelty of this work lies in its target-oriented process design, which integrates emissions, energy metrics, and deployment context within a unified simulation and evaluation framework. The approach provides a structured path for aligning CCU technology with regional policy, infrastructure, and sustainability goals.

In conclusion, the study demonstrates that strategic system integration—incorporating heat recovery, byproduct reuse, and renewable alignment—can enable CCU technologies to meet decarbonization targets while improving techno-economic viability. By comparing two distinct pathways under varying regional conditions, this research delivers a flexible framework for guiding the design and implementation of next-generation synthetic fuel and chemical systems.