2025 AIChE Annual Meeting

(77c) Synthetic Aviation Fuel from Co-HTL of Anaerobic Digestion-Derived Biosolids and Wastewater-Grown Algae: A Combined Experimental Study and Techno-Economic Assessment

Authors

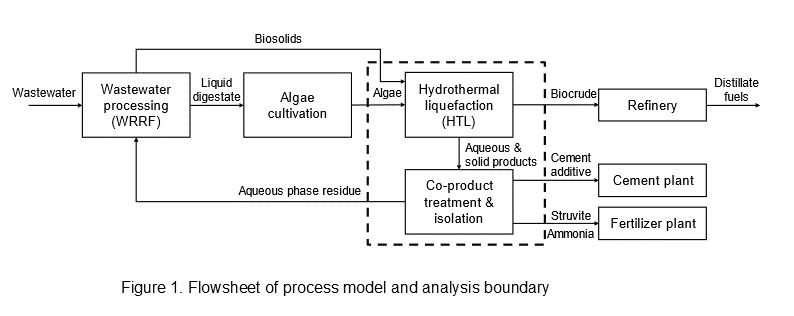

A techno-economic analysis (TEA) was performed to assess the feasibility and economic potential of the produced fuel using this pathway. The process boundary and the flow of materials are shown in Figure 1. For this analysis, a WWRF with a 100 million gallons per day treatment capacity produces is considered. Such a site produces about 52 dry tons/day of biosolids and has a potential of producing about 25 dry tons/day of algae from its nutrient-rich AD centrate.2 For additional revenue, co-products such as fertilizers in form of struvite and cement additives from HTL solids are also considered. The minimum fuel selling price (MFSP) of fuel from blended feedstock of WW-grown algae and biosolids was $8.30 per gasoline gallon equivalent. The impact of different blend ratios and scales on the MFSP of fuel was also forecasted. A sensitivity analysis was also performed to evaluate the impact of various parameters on MFSP. Plant specific parameters such as HTL scale and capital cost were found to have the most significant impact on the MFSP of fuel.

References

(1) Watkins, J. D.; Kumar, A.; Valdez, P. J. Whole Algae Hydrothermal Liquefaction and Upgrading: A review of progress and challenges and insight into the future; PNNL-37209; Pacific Northwest National Laboratory (PNNL), Richland, WA (United States), United States, 2025. https://www.osti.gov/biblio/2500903

(2) Kumar, A.; Watkins, J. D.; Cronin, D. J.; Fox, S. P.; Schmidt, A. J.; Valdez, P. J. 2024 Case Study: Hydrothermal Liquefaction of Biomass Sources at a Wastewater Treatment Facility; PNNL-37230; Pacific Northwest National Laboratory (PNNL), Richland, WA (United States), United States, 2025. https://www.osti.gov/biblio/2499474