2025 AIChE Annual Meeting

(54h) Synthesis and Titanium Speciation Control in Ti-CHA Zeolites Via a Fluoride-Free Method

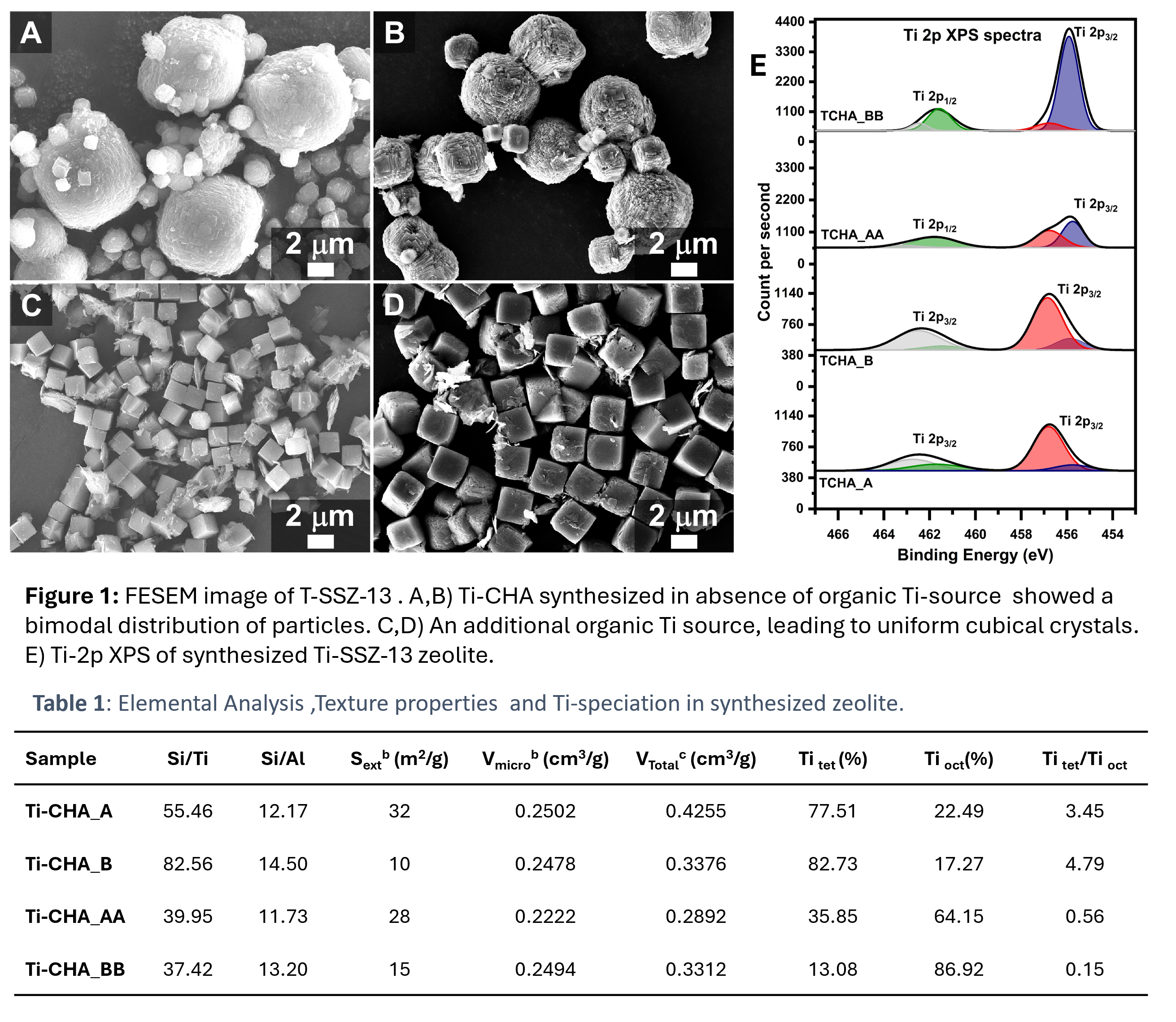

Titanium-containing zeolites are widely studied for their catalytic versatility, particularly due to the Lewis acidity of framework Ti(IV) centers. While medium- and large-pore titanosilicates like TS-1, Ti-Beta, and Ti-MWW are well-established, small-pore titanium-containing zeolites such as Ti-CHA(Ti-SSZ-13) has been synthesized in presence of hydrofluoric acid[1] or fluoride ion source[2]. In this work, we report the first successful synthesis of Ti-CHA in absence of fluoride source, achieving high titanium incorporation into the zeolite framework. Further we have explored the tuning of tetrahedral Ti-species and octahedral Ti-species using additional Ti-source in mother liquor. The resulting Ti-CHA zeolites exhibit well-faceted cubic morphologies and distinct textural properties. X-ray photoelectron spectroscopy (XPS) indicated both tetrahedral and octahedral coordination states of Ti. Samples synthesized without additional Ti sources showed a higher fraction of tetrahedral Ti (up to ~83%), suggesting effective incorporation into the framework. Conversely, the use of excess Ti precursors led to a higher proportion of octahedral Ti species, often associated with extra-framework sites. Elemental analysis revealed Si/Ti ratios ranging from 37 to 82, depending on the precursor and synthesis conditions. These results demonstrate how precursor identity and synthesis parameters influence the physicochemical properties and Ti coordination environment in Ti-CHA zeolites. The materials developed here are promising candidates for applications in shape-selective oxidation, gas separation, and NH₃-SCR catalysis under harsh conditions, due to their thermal stability and controlled Ti incorporation.

References

[1] E. A. Eilertsen, S. Bordiga, C. Lamberti, A. Damin, F. Bonino, B. Arstad, S. Svelle, U. Olsbye, K. P. Lillerud, ChemCatChem 2011, 3, 1869–1871.

[2] Y. Kunitake, T. Takata, Y. Yamasaki, N. Yamanaka, N. Tsunoji, Y. Takamitsu, M. Sadakane, T. Sano, Microporous and Mesoporous Materials 2015, 215, 58–66.