2025 AIChE Annual Meeting

(392l) Supply Chain Optimization in the Collection of Used Cooking Oil

Authors

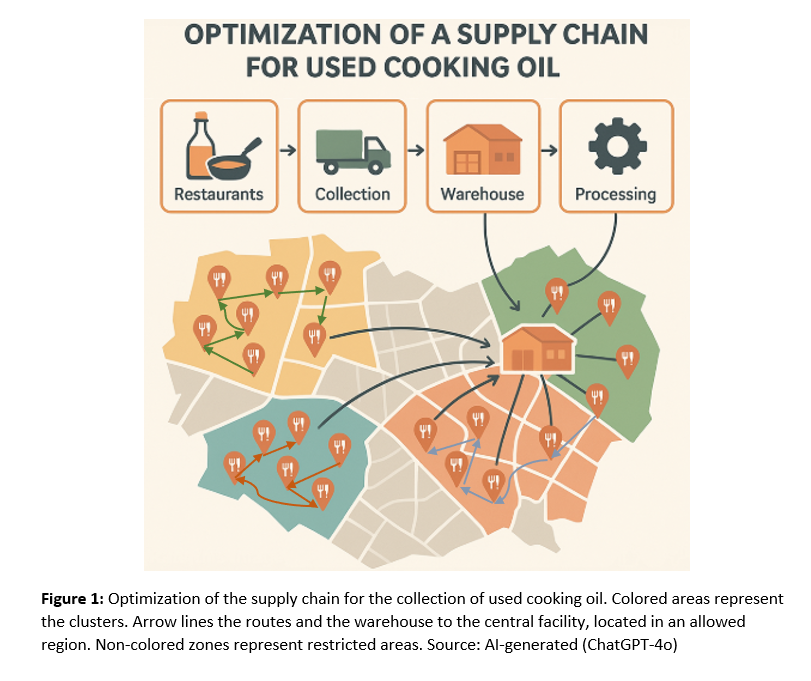

The clustering problem was formulated as a k-means problem and addressed using machine learning (ML) heuristics and as a mixed-integer non-linear programming (MINLP) problem. In the k-means problem, optimality conditions were tested based on [3]. After obtaining the clusters, the routing problem was posed as a capacitated vehicle routing problem (CVRP). In [2], the problem was solved by arranging the locations in a priority rank, and from that list, a subset of them was chosen to set a route. Although initially found via heuristics [2], this route was formulated as a traveling salesperson problem (TSP) and solved using Google's OR Tool [4] and Concorde [5]. The original problem contained extra constraints that were verified post-solution. In contrast, we posed the original problem as a monolithic CVRP and solved it using metaheuristics implemented in the library pyVRP [3]. Finally, having set the clusters and defined the routes, a central recollection point is located considering local policies for industrial facility location. The restricted areas and their complementary regions were decomposed using simplexes using the Shapely [6] library in Python, which led to a disjunctive programming formulation of the location of the distribution center.

Performance metrics such as time of execution and quality of the solution related to the objective of the problem were computed to compare the different solution algorithms. As an example of the improved performance using the right analytic tools compared to metaheuristics, in the clustering problem, using the k-means formulation led to a 13.3% better solution based on the total distance to the centroids compared to the solutions reported in the literature [2] and found it 200 times faster. This shows how the correct formulation and matching of analytics, optimization, and machine learning techniques can lead to significant improvements in addressing real-world applications aimed at improving the sustainability of our society.

References

[1] Tatiana Bahamon, Every year Bogotá generates more than 35,000 tons of used oil and does not use it (in Spanish), UNAL Journal, Mar. 2025. [Online]. Available: https://periodico.unal.edu.co/articulos/cada-ano-bogota-genera-mas-de-3…

[2] J. S. Rodríguez, A. Orjuela, and J. G. Cadavid, Characterization and optimization of a used cooking oils collection chain – Study case Bogotá, Colombia, Chem. Eng. Res. Des., vol. 184, pp. 59–71, Aug. 2022, doi: 10.1016/j.cherd.2022.05.049.

[3] N. A. Wouda, L. Lan, and W. Kool, PyVRP: a high-performance VRP solver package, Inf. J. Comput., vol. 36, no. 4, pp. 943–955, 2024, doi: 10.1287/ijoc.2023.0055.

[4] L. Perron and V. Furnon, OR-Tools. (May 07, 2024). Google. [Online]. Available: https://developers.google.com/optimization/

[5] D. Applegate and W. Cook, Concorde TSP solver. 2006.

[6] S. Gillies et al., Shapely. (Apr. 03, 2025). Zenodo. doi: 10.5281/ZENODO.5597138.