2025 AIChE Annual Meeting

(235d) Success of Selective Fermentation to Treat Variable Swine Wastewater at Different pH for Volatile Fatty Acids (VFAs) Production.

Authors

Global populations have been estimated to rise to 9.8 billion by 2050, subsequently raising demand for natural resources (Nagarajan et al., 2019). With global populations rising, animal products will continue to rise to ensure food security. Pork is one of the most common proteins for consumption, averaging 45 lb of pork meat per person, per year (Zhou et al., 2021) and produced in centralized Confined Animal Feeding Operations (CAFOs) or local small-scale livestock farming. From these farms, large volumes of manure are produced, averaging about 5 L of wastewater per day per pig. In recent decades, concentrated swine farming has greatly increased in the United States with the number of hogs and pigs reaching 75.0 million head on U.S. farms (Zhang et al., 2018). This causes a significant amount of waste that needs to be properly processed instead of being released into the environment and therefore causing the release of excess nutrients like nitrogen and phosphorus into the environment as well as the larger potential of wasted carbon emitted as methane from manure storage and disposal. Fermentation of swine wastewater is a way to valorize the organic carbon available in swine manure, allowing capture in the form of short and medium chain volatile fatty acids (VFAs) (Deng et al., 2023; Li et al., 2020).

Most VFAs, valuable short-chain fatty acids (SCFAs, C2–C6), are currently produced from petrochemicals, though biomanufacturing from waste streams shows strong potential (Agnihotri et al., 2022; Ramos-Suarez et al., 2021). VFAs—such as acetate, propionate, and butyrate—are intermediates of anaerobic digestion, which involves hydrolysis, acidogenesis, acetogenesis, and methanogenesis. Suppressing methanogens via pH control (acidic or alkaline) promotes VFA accumulation, with production efficiency ranging from 15–25% at pH 5 to 35–50% at pH 9. Separation methods include membranes, ion exchange, and distillation, though further development is needed (Zhu et al., 2023; Singh et al., 2023). Mixed-culture VFAs can serve as external carbon sources in nutrient removal and as feedstocks for bioplastics, chain elongation, and bio-aviation fuels. This study explores VFA production from swine wastewater at pH 5 and 9, providing baseline data for future AnMBR integration and co-fermentation with FOG—two co-located waste streams.

Materials and Methods

Activated sludge was collected from the anoxic selector basin at the wastewater treatment plant located in Manhattan, Kansas. The activated sludge was allowed to be settled for 24 hours and 3L of the thickened solids were aliquoted equally to two 2-L reactors to serve as the inoculum. Each fermenter received 1.5L ml of settled sludge in a 2-L bottle. After sludge analysis, casein, and cellulose, representative proteins, and carbohydrate substrates, were dosed to the fermentation reactors at 3.93 g/L, each. After the addition of casein and cellulose, TCOD and SCOD were monitored periodically during batch operation along with VFAs. Once an increase followed by a stabilization of the SCOD and VFAs was noted, a second dose of casein and cellulose was added again at 3.93 g/L, 10 days after the first dose. Analysis of TCOD/SCOD and VFA concentrations were measured in same frequency until an additional increase in VFA and stabilization occurred. The initial characteristics of the inoculum after analysis, including TCOD and SCOD concentration were 19.9 and 6.3 g/L, whereas total solid (TS) and volatile solid (VS) of the substrate were 12.8 and 10.1 g/L, respectively.

Following acclimation of inoculum, swine wastewater was introduced as the substrate for VFA production. The reactors have been maintained at a 10-day hydraulic retention time (HRT), 30 degrees Celsius, and stirred at 350 RPM for 600 days as of writing. The pH of both fermenters is maintained at 5 and 9 respectively. Removed fermentation broth was centrifuged, and the supernatant was discarded after samples for VFA analysis. The remaining solids are then resuspended in influent wastewater and added back into the fermenters to maintain a high solids retention time (SRT). Ideally, SRT would be infinite so as to maintain higher microbe populations and therefore higher VFA production, but some solids are lost during centrifugation. The actual SRT of the fermenters have been calculated by finding the total solids content of the bulk fermentation liquid and the supernatant after centrifugation. The average SRT of the pH 5 fermenter is 27 days and the average SRT of the pH 9 fermenter is 50 days.

The characterization of total and volatile suspended solids was carried out weekly, according to Standard Methods (2540D and 2540E; Standard Methods Water and Wastewater). Weekly total chemical oxygen demand (TCOD) and SCOD sludge analysis was performed using HACH 822 TNT kits ranging from 20-1500 mg/L concentration using HACH DR 3900 spectrophotometer at 1:500 and 1:250 dilutions, respectively. The pH was measured and readjusted daily using Oakton pH 550 benchtop pH meter using HCl 4M and NaOH 5M. Centrifugation of the effluent was done at 15054 rcf with Eppendorf 5920 R (Eppendorf, Hamburg, Germany). Hydrogen and methane were analyzed using Gas-Chromatography (GC) with a thermal conductivity detector (TCD) using Argon as a carrier gas at a flow rate of 8.8 mL/min and pressure of 88.8 kPa. Temperatures of injection, column, and detector were 200, 80, and 150 ℃, respectively. For VFA quantification, the HPLC (Shimadzu LC-20AT, USA) with an Aminex HPX-87H column (300 mm × 7.8 mm, Bio Rad Corp., USA) equipped with two detectors: photodiode array and refractive index detectors was used at 0.65 mL/min pump flow rate and 50 ℃ oven temperature with 2.5 mM sulfuric acid as eluent.

Results and Discussion

The KSU team has been operating bench-scale swine waste fermenters at pH 5 and 9 for over two years and has preliminary data that will assist in the conversion of a pilot-scale AnMBR from anaerobic digestion to fermentation. Current experiments with the fermenters are on the effect of heat shocking the broth at 60°C to evaluate its effect on fermentation efficiency and solids retention. The bench-scale fermenters have issues with solids retention due to the limitations of the centrifuge the team uses to separate out the solids when removing and replacing broth with fresh swine waste. Ideally, all solids are separated out using the centrifuge and can be added back to the fermenters, but the maximum speed of the centrifuge is not enough to fully separate the broth. This results in some loss of solids and subsequently lowers the fermentation efficiency. Heat shocking the broth before centrifugation has improved solids separation and improved fermentation efficiency. The team does not expect this solids separation issue during operation of the pilot-scale AnMBR as the membrane will allow for effective dynamic separation of VFA-rich permeate from the solids in the system, resulting in minimal solids loss.

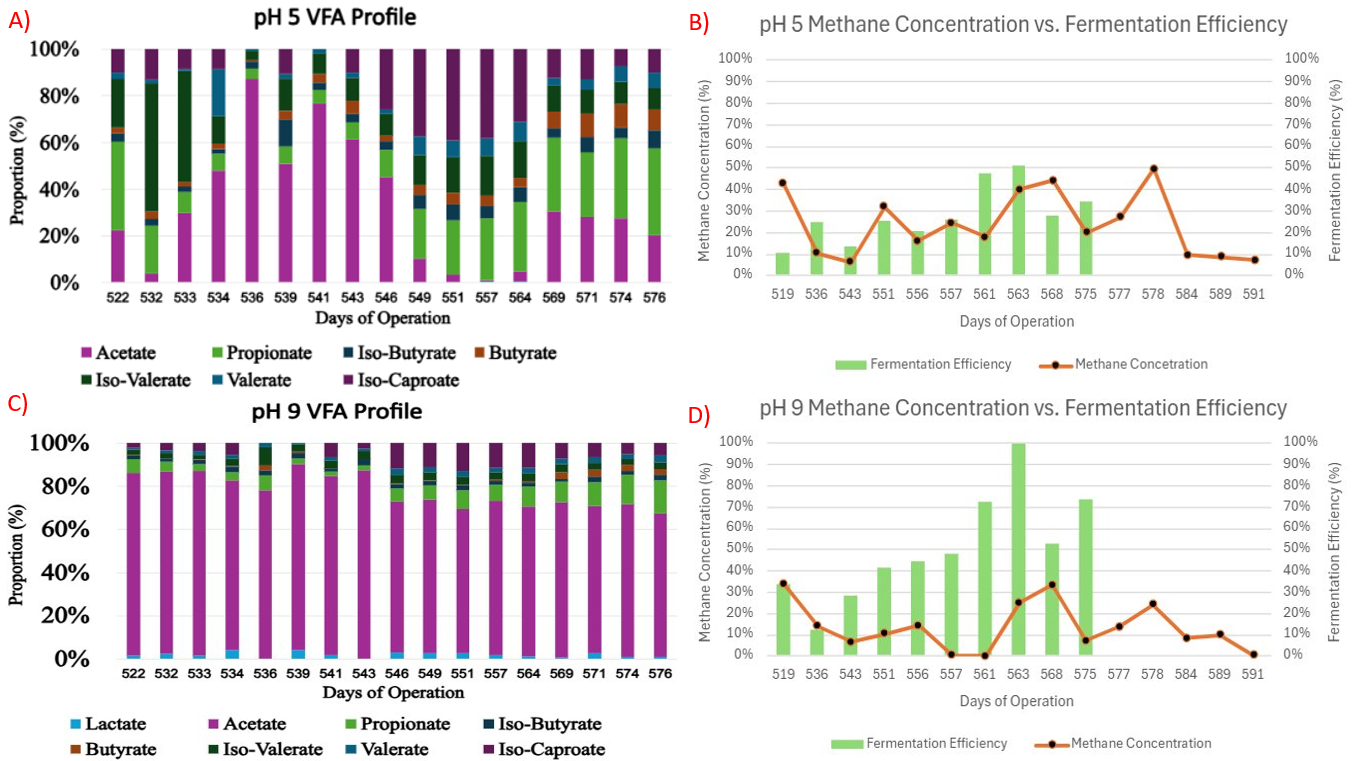

The pH 5 fermenter has a variable profile of VFAs produced, with the primary products being acetate, propionate, and iso-caproate. The concentrations of each product can fluctuate greatly over time and is also influenced by the variable strength of the organics (COD) in the input swine wastewater. Figure 1(a) below shows the VFA profile of the pH 5 fermenter. Figure 1(b) shows methane concentration of gas in headspace and fermentation efficiency, which typically ranges from ~20-30%. The order of predominance of VFAs from swine wastewater selective fermentation at pH 5 is as follows: Acetate > Propionate > Iso-Caproate. As the pH is acidic, the VFAs are in solution rather than their conjugate bases, resulting in high surface tension and a greater tendency for foaming events. Foaming is the primary operational challenge for fermentation at pH 5 and this will be taken into account during testing of the pilot-scale AnMBR.

The pH 9 bench-scale fermenter exhibited a very consistent VFA profile, as seen in Figure 1(c). The primary product is acetate, with it making up at least 70% of the total amount of VFAs produced. This lends towards fermentation at pH 9 being a better candidate for selective fermentation, allowing for optimized downstream processes. Fermentation efficiency is also significantly higher in the pH 9 fermenter, occasionally peaking above 70%, as seen in Figure 1(d).

Works Cited

Agnihotri, S., Yin, D.-M., Mahboubi, A., Sapmaz, T., Varjani, S., Qiao, W., Koseoglu-Imer, D.Y., Taherzadeh, M.J. 2022. A glimpse of the world of volatile fatty acids production and application: a review. Bioengineered, 13(1), 1249-1275.

Deng, L., Zheng, D., Zhang, J., Yang, H., Wang, L., Wang, W., He, T., Zhang, Y. 2023. Treatment and utilization of swine wastewater–A review on technologies in full-scale application. Science of The Total Environment, 880, 163223.

Li, X., Guo, L., Liu, Y., Wang, Y., She, Z., Gao, M., Zhao, Y. 2020. Effect of salinity and pH on dark fermentation with thermophilic bacteria pretreated swine wastewater. Journal of Environmental Management, 271, 111023.

Nagarajan, D., Kusmayadi, A., Yen, H.-W., Dong, C.-D., Lee, D.-J., Chang, J.-S. 2019. Current advances in biological swine wastewater treatment using microalgae-based processes. Bioresource technology, 289, 121718.

Ramos-Suarez, M., Zhang, Y., Outram, V. 2021. Current perspectives on acidogenic fermentation to produce volatile fatty acids from waste. Reviews in Environmental Science and Bio/Technology, 20(2), 439-478.

Singh, R., Palar, S., Kowalczewski, A., Swope, C., Parameswaran, P., Sun, N. 2023. Adsorptive recovery of volatile fatty acids from wastewater fermentation broth. Journal of Environmental Chemical Engineering, 11(5), 110507.

Zhang, M., Liu, Y.-S., Zhao, J.-L., Liu, W.-R., He, L.-Y., Zhang, J.-N., Chen, J., He, L.-K., Zhang, Q.-Q., Ying, G.-G. 2018. Occurrence, fate and mass loadings of antibiotics in two swine wastewater treatment systems. Science of the Total Environment, 639, 1421-1431.

Zhou, S., Ding, R., Meng, F., Wang, X., Zhuang, Z., Quan, J., Geng, Q., Wu, J., Zheng, E., Wu, Z. 2021. A meta-analysis of genome-wide association studies for average daily gain and lean meat percentage in two Duroc pig populations. BMC genomics, 22, 1-13.

Zhu, X.-Z., Wang, L.-F., Pan, X.-R., Zhang, F., Huang, M.-S., Li, W.-W., Liu, H.-Q. 2023. Selective separation of volatile fatty acids, nitrogen and phosphorus from anaerobic acidogenic fermentation via forward osmosis membrane process. Chemical Engineering Journal, 453, 139871.