2025 AIChE Annual Meeting

(390ac) Study on Thermal Transistor Heating-up and Refrigerating from Heat below 80°C By Batch Test with 2 Columns Device of Absorption Heat Pump

Authors

Waste gas below 200°C can be recovered as hot water at approximately 80°C using commercially available waste heat recovery heat exchangers. Our research group has been conducting studies on high-temperature generation using lithium bromide LiBr/water type of absorption heat pump for a waste heat recovery. In bench-scale experiments, we have successfully demonstrated that an absorption heat pump can generate hot air above 120°C and steam above 100°C from 80°C hot water.

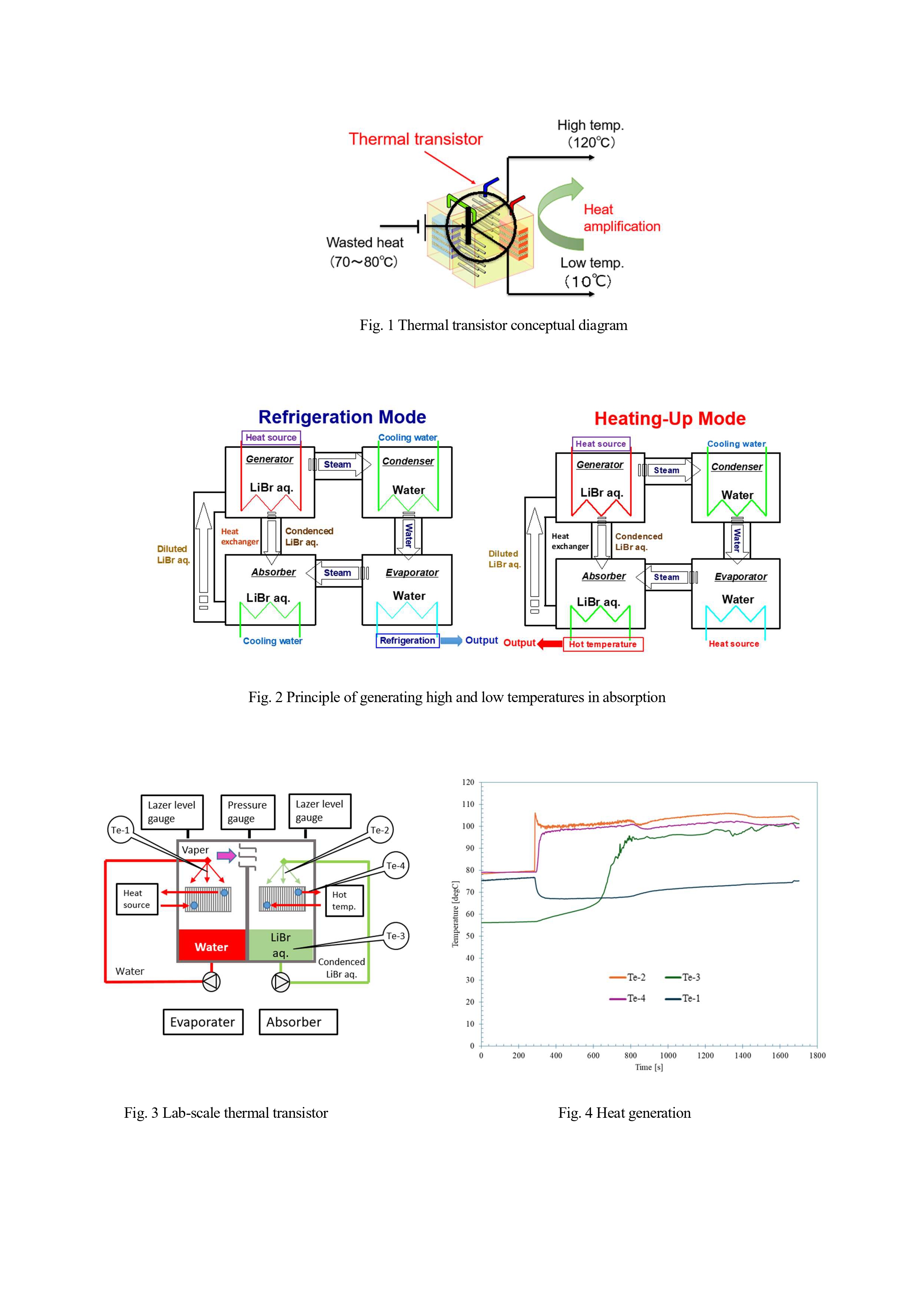

Absorption heat pumps were originally developed as chillers, but by incorporating a high-temperature generation cycle, they can simultaneously produce both low and high temperatures from hot water at approximately 80°C. Based on an analogy with the transistor function in electrical circuits, we refer to this system as a "thermal transistor" and propose the system shown in Fig. 1.

The principle of an absorption heat pump that generates both high and low temperatures is outlined in Fig. 2. The LiBr/water absorption heat pump is composed of four columns: an absorber, an evaporator, a regenerator, and a condenser for each mode of chiller and heating-up. Hence the thermal transistor requires a total of eight columns. However, the goal in this study is to create a thermal transistor with six columns to recover the waste temperature at 80 °C and simultaneously generate higher temperature than 120 °C and lower temperature 7 °C by integrating the regenerators and condensers. This will simplify the equipment and reduce costs, although it will complicate control.

In this study, a lab-scale device consisting of two columns was built and the performance of fundamental heat and mass transfer was examined to establish the optimal system configuration and operating conditions for a 6 columns thermal transistor. Batch examination on high and low-temperature generation and regeneration of the solution were conducted. Additionally, simulations were performed for each operating mode. The two-columns examination device is shown in Fig. 3, and the temperature changes at four points from the high-temperature generation experiment are shown in Fig. 4 as an example. It was observed that the solution temperature in the absorber improved immediately over 100 °C from the heat source at 75 °C. If heat loss is ignored or a continuous process is employed, the analysis based on the modeling shows that the temperature can be possible to achieve at 120 °C. In the low-temperature generation experiment, the water was cooled from 14°C to 7°C. It was demonstrated that by adjusting the operating conditions, it is possible to configure a thermal transistor that simultaneously generates both high and low temperatures. In the next step, a continuous examination will be performed by a devise with 6 columns thermal transistor.