2025 AIChE Annual Meeting

(671h) Spray Homogeneity and Stability in Electrospray Processes

Authors

Electrospray deposition offers a solution to this challenge. The process uses an electric field to disperse a liquid into a fine mist of charged droplets, which deposit as uniform, nanoscale films. This mechanism works well with a broad range of materials and allows careful control of coating thickness. More importantly, it lends itself to continuous manufacturing when adapted into multi-nozzle systems. With its blend of precision, material compatibility, and potential for scale-up, electrospray stands out as a promising technique for producing high-performance selective layers.

This work explores electrospray as a viable platform for producing ultrathin, uniform coatings with the level of control and scalability that traditional methods lack. At the core of the process is the interaction between the applied electric field and the liquid at the spray tip, which creates fine droplets that form dense, continuous films upon deposition. When extended into multi-nozzle configurations, the technique holds potential for continuous operation while preserving coating quality. Its flexibility in handling a wide range of materials and its capacity to produce nanometer-scale layers make it well-suited for high-performance separation membranes, and potentially other thin-film technologies that require uniformity at scale.

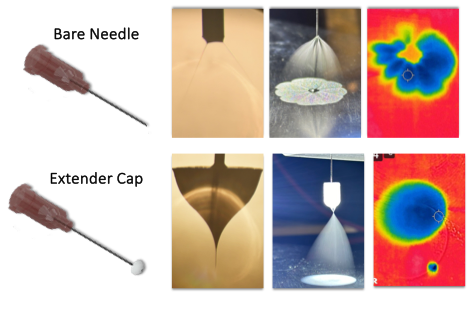

Our investigation centered on how electrospray stability influences spray homogeneity, a critical factor in ensuring reliable thin-film formation. A key finding came from modifying the needle geometry by adding an extender cap. This small change had a noticeable effect on the behavior of the Taylor cone, increasing its size and stabilizing its shape. With this configuration, the spray system was able to maintain a single, steady jet across a wider range of flow rates and applied voltages. This improved balance between electric and capillary forces marks a step forward in controlling deposition at the fluid–field interface.

Images taken during spray operation further supported these observations. With standard needle setups, small shifts in voltage or position often triggered unstable multi-jet formation and irregular spray behavior. The modified design, by contrast, produced a narrow, centered spray plume with more uniform droplet dispersion. This improvement in spatial control reduced spray variability and led to more consistent deposition—key for any process designed to run continuously.

To assess how evenly the spray covered the target surface, we used thermal imaging based on the cooling effect of solvent evaporation. The resulting temperature maps revealed consistent coverage in the extended cap setup, with no gaps or irregularities at the edges. These results matched the optical and structural observations, confirming that a stable spray translates directly into more effective coatings.