2025 AIChE Annual Meeting

(318a) Solvothermal Liquefaction of Agricultural Waste Using Crude Methanol Generated from Flare Gas Sites

Authors

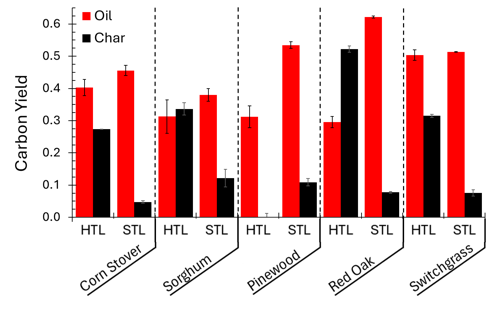

Methane produced from stranded oil wells is commonly generated near agricultural waste sources and requires flaring, a process that contributes more than 1.4 gigatons of CO2-eq across the 16,000 global flare sites. M2X Energy has developed an alternative technology capable of converting methane into a methanol-rich liquid form but would require refinement to become pure methanol. Our alternative approach efficiently converts waste biomass with the addition of the crude methanol solvent, termed solvothermal liquefaction (STL). In this study, we performed comparative tests evaluating the improvement in biocrude yield between HTL and STL using a wide variety of agricultural waste feeds.

STL reveals a 20% increase in biocrude yield improvements and >50% reduction in solid yield compared to HTL when woody feedstocks are converted. The same improvement in biocrude is not observed for other feeds, such as switchgrass; however, all feeds have a noticeable reduction in solid char byproducts. The reduction in char yield with the addition of methanol can be attributed to an improved reactivity of the primary char or a minimization of secondary reactions that redeposit as solids. These results highlight the potential benefits of a solvothermal approach with a “crude” methanol feed by reducing the required waste disposal costs of residual solids for a wide variety of green wastes, as well as improve the process reaction efficiency of a liquefaction process.