2025 AIChE Annual Meeting

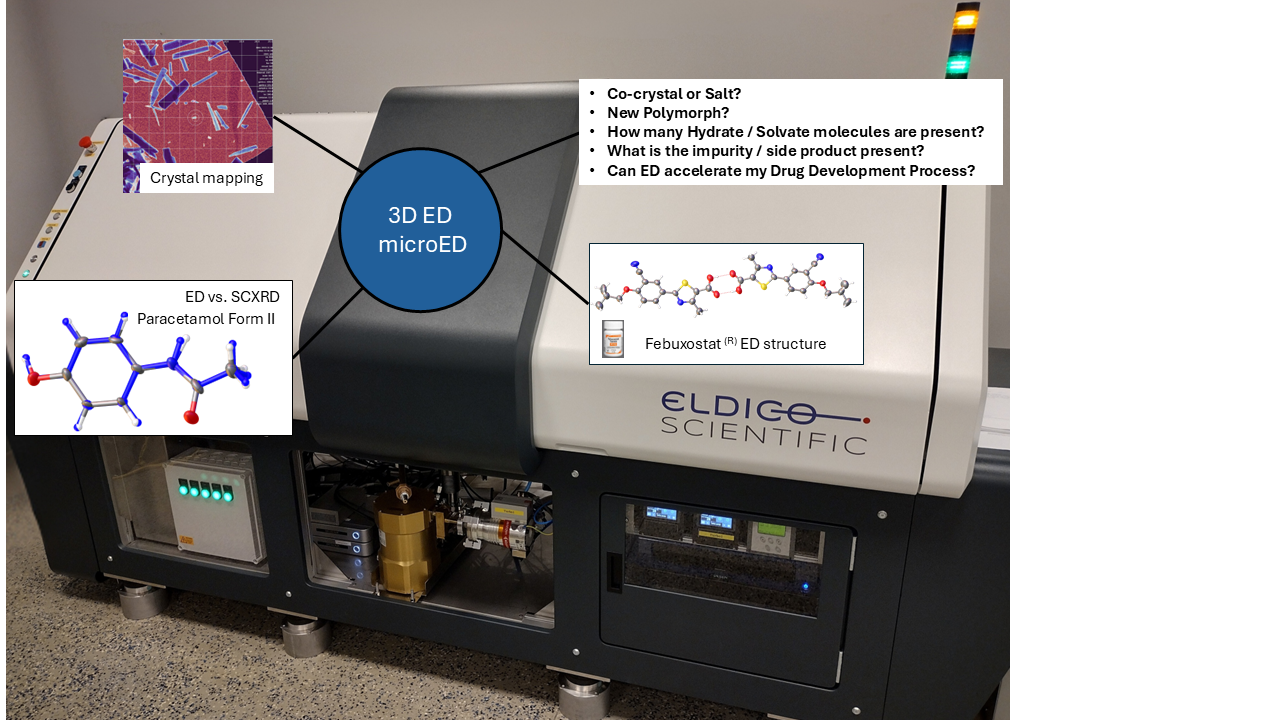

(702d) Solid Forms’ Characterization Using Electron Diffraction: Unvealing the Unseen and Undetectable

Authors

We would like to show case, not only the technology, but emphasize in the advantages and capabilities of having a dedicated device for electron diffraction experiments. Especially for the Pharmaceutical and (Agro-)Chemical companies. Moreover, we would compare the technology to existing technologies like SC-XRD or XRPD, highlight new fields of applications like “crystal mapping” for phase or impurity identification and present some studies where ED has been a game changer for API’s structure elucidation.[4] Especially, when very little amounts of sample are present or other available analytical techniques fail to provide an answer.

References:

[1] Gruene, E. Mugnaioli. Chem. Rev. 2021, 121, 11823-11834.

[2] There are two commercial companies that have developed and sell electron diffractometers: Eldico Scientific AG, Rigaku. a) Simoncic, et. al., Acta Cryst., 2023, E79, 410-422. b) S. Ito, et al., CrystEngComm., 2021, 23, 8622 – 8630.

[3] Personal (short) selection of a growing list of publications a) F. Woods, et. al., Nature Communications, 2023, 14, 4725. b) D. T. Ungur, et. al., Cryst.Eng.Comm., 2024. 26, 4295 – 4304. c) E. Biehler, et. al. J. Appl. Cryst. 2025. 58, 398-411.

[4] a) P. Sieger, et. al., European Journal of Pharmaceutical Sciences. 2023,186, 106447. b) D. T. Ungur, et. al., CrystEngComm, 2024,26, 4295-4304.