2025 AIChE Annual Meeting

(226e) Simultaneous Measurement of Density and Viscosity of n-Dodecane and Hexane Using a Balanced Torsional Resonator-Based Sensor

Authors

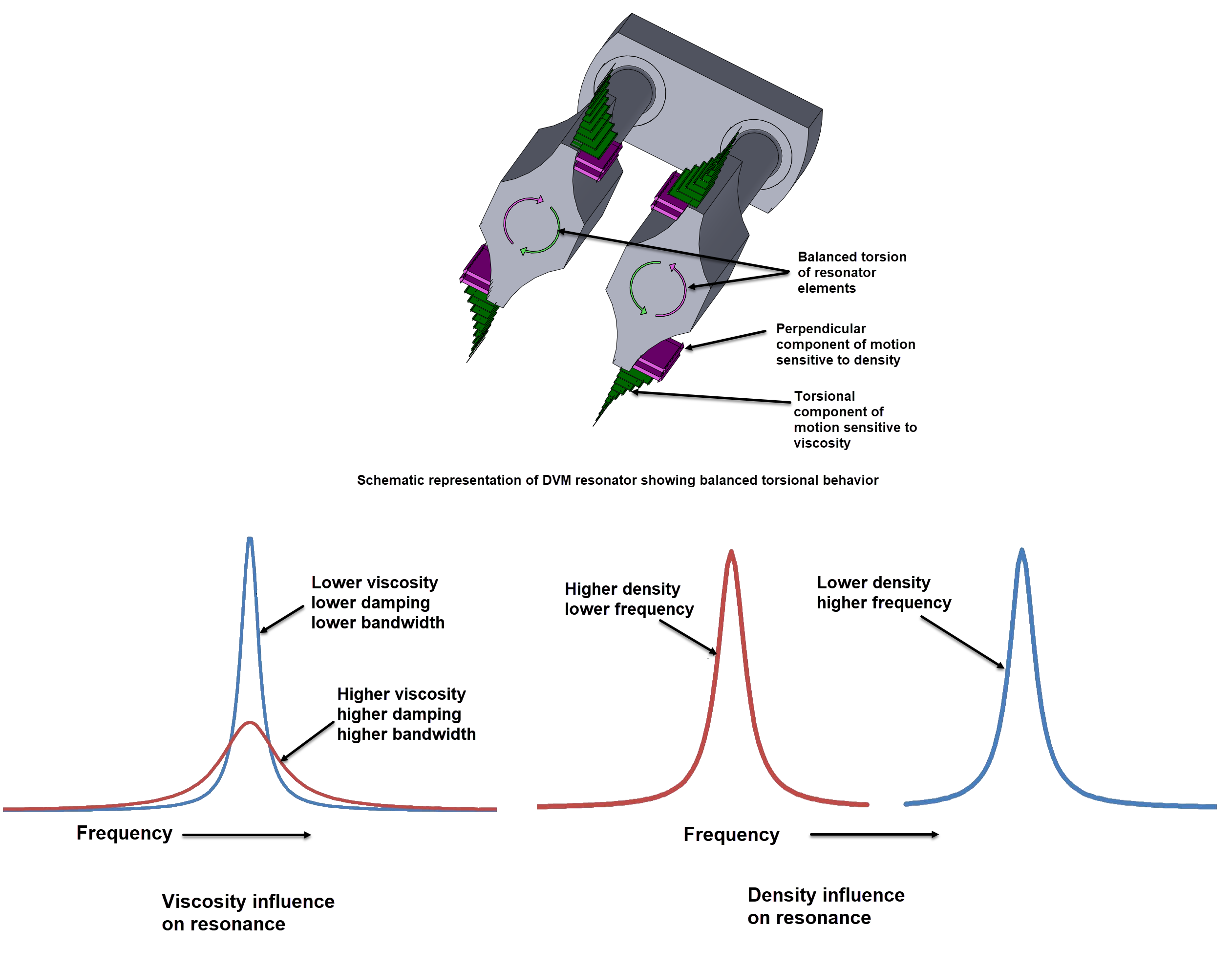

The Rheonics DVM high pressure, high temperature density and viscosity meter was developed specifically to meet these challenges. It is based on a patented balanced torsional resonator (shown in figure) whose resonance frequency and bandwidth are sensitive to the fluid density and viscosity in which it is immersed. The effects of viscosity and density are shown in the figure. The total sample volume required is 0.7 milliliters; all wetted parts are made of titanium grade 5, ensuring high chemical resistance and mechanical integrity. A Pt1000 temperature sensor is situated in close proximity to the measurement chamber, ensuring accurate temperature measurements that are essential to measurement accuracy.

The torsional balanced resonator’s resonance characteristics are tracked by a proprietary electronics unit that measures the damping (resonance bandwidth) and resonance frequency of the sensing element. Changes in the density of the fluid influence the resonance frequency of the sensor. Changes in viscosity change the damping of the sensor – its resonance bandwidth. By simultaneously measuring the frequency and damping of the sensor, the density and viscosity of the fluid can be measured with high accuracy, precision and repeatability.

Calibration of the DVM is carried out using NIST certified calibration fluids for lower pressure, high viscosity ranges. Low-viscosity high pressure calibration uses pure alkanes including n-dodecane and n-hexane, with reference values derived from NIST thermophysical properties databases over temperature ranges from 283 to 473 K and pressures from 0.1 to 200 MPa, or up to the pressure-freezing pressure for a given temperature. Pressure stiffening effects of the resonator material become significant at the high end of the pressure range, and are measured by measuring the frequency increase of the resonator operating in high-pressure nitrogen atmospheres, with corrections for the density increase of the nitrogen.

Density accuracy is 0.001 g/cc; viscosity accuracy is within 5 % of reading above 1cP; 0.1 cP below 1 cP. Reproducibility is within 1 % of reading.

Figure: DVM balanced torsional resonator showing torsional (green arrows) and linear (magenta arrows) components of displacements of sensing element. Effect of viscosity and density on DVM resonance behavior