2025 AIChE Annual Meeting

(313f) A Simplified Approach to the Design of Thermochemical Storage Processes

Authors

Giuseppe Procopio, University of Rome La Sapienza

Stefano Cerbelli, Università di Roma Sapienza

Maria Cristina Annesini, Università di Roma Sapienza

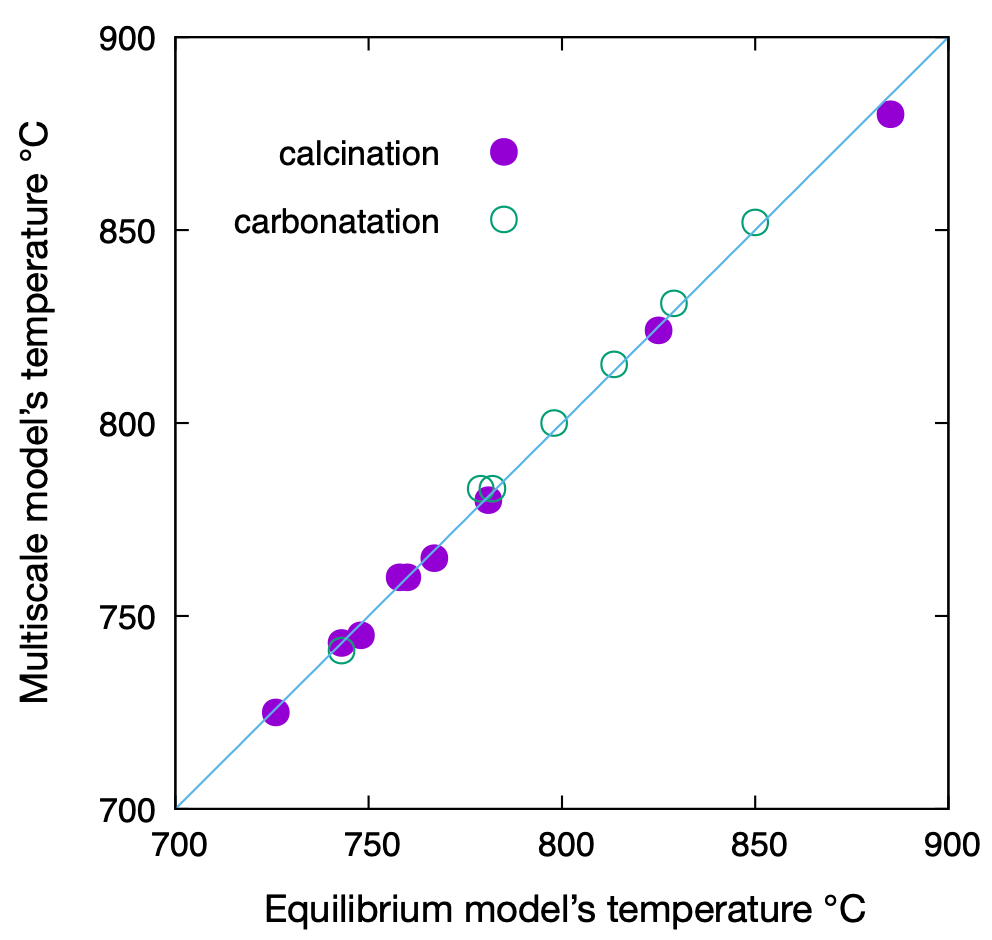

Thermochemical energy storage exploiting reversible gas-solid reactions is a promising technology allowing to store high energy density for a long period of time (e.g. seasonal storage) with minimal or no energy losses. Several reacting materials have been investigated in the literature, such as metal hydroxides, metal carbonates, and metal oxides. The choice between all these systems often results from the compromise between environmental sustainability, safety and overall performance. This latter depends on thermodynamics parameters (enthalpy and Gibbs free energy of the reaction, which impact upon energy density and turning temperature, respectively) as well as transport and kinetic parameters. In addition, hysteresis phenomena which may compromise the stability under reaction looping of the material must be taken into account. The present work aims at developing a simplified equilibrium-based approach requiring minimal computational effort, that can be used for the swift screening of a wide selection of perspective materials and/or for the choice of the working reaction temperature and gas composition. To validate the approach, predicted temperature and composition profiles are compared to a multiscale model of a fixed-bed reactor, which takes into detailed account the existence of non-equilibrium conditions, such as the finite rate of the chemical reaction, mass transport resistances in the pores of the granular material, heat transfer limitations, and pressure drops. The validation has been carried out by choosing the carbonation/calcination reaction (charge and discharge phase) as a representative example of thermochemical storage reacting system. The comparison shows that the operating reaction temperature is predicted within a 5% error with respect to the full numerical solutions accounting for transport and reaction times (see Figure 1). Excellent agreement is also obtained as regards the composition of the gas phase. For the case study investigated, the prompt and robust response allowed by the simplicity of its numerical solution makes the approach proposed a handy tool, ideally suited to be integrated with the analysis of the upstream and downstream processes for the optimization of the entire storage process.

Figure 1: Comparison of the operating temperatures reached during the charge (purple points) and discharge (green points) phases of calcium looping, as obtained from the equilibrium and the multiscale models.