2025 AIChE Annual Meeting

(556b) Shear Thickening Flow in Pigment Dispersions: Practical Challenges and Predictive Solutions

Authors

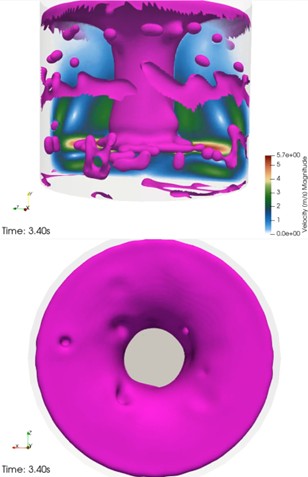

This study addresses these challenges by integrating practical plant observations with theoretical and computational approaches. We will examine common plant issues related to shear thickening and assess the applicability of existing empirical correlations for predicting vortex formation and drawdown in mixing vessels. Furthermore, we leverage Computational Fluid Dynamics (CFD) using MStar CFD software to model these complex flow behaviors. Utilizing rheological characterization of TiO2 suspensions, such as the work by Zupančič, Lapasin, and Turner (1996), our simulations aim to provide predictive capabilities for optimizing dispersion processes. Initial simulations have successfully captured the experimentally observed "donut" shape within the mixing vessel (as shown in the included figure), demonstrating the potential of this integrated approach for understanding and managing shear thickening in industrial settings