2025 AIChE Annual Meeting

(699a) Self-Driving Hte Labs for Synthetic Molecule Process Development

Authors

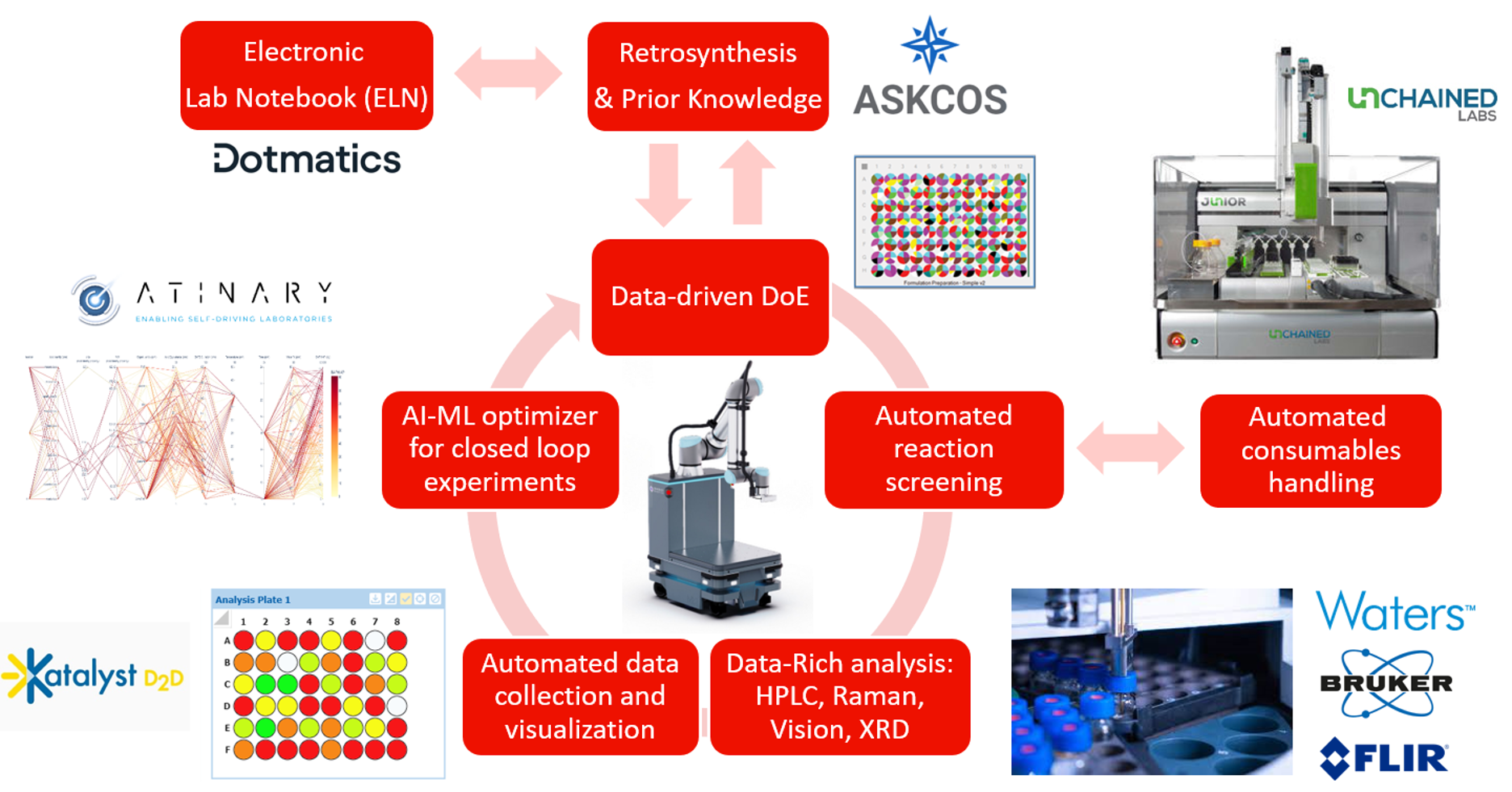

Here, we present Takeda’s vision for fully self-optimizing HTE workflows within our Synthetic Molecule Process Development (SMPD) department, with the ultimate goal of creating SDLs with workflows optimized for a variety of general applications needed in synthetic molecule drug development. Such workflows will begin by leveraging internal databases (e.g., our Dotmatics ELN) and/or external tools (such as ASKCOS for retrosynthesis and route planning) to determine the scope of the parameter space that will be explored. By connecting these tools to other commercial platforms such as Katalyst (for reaction planning) and Atinary (for initial DoE creation and subsequent Bayesian Optimization), we will be able to autonomously generate reaction conditions to be screened and then perform the experiments using HTE automation equipment (e.g., Juniors from Unchained Labs). A variety of data rich experimentation approaches will be used to collect data on each reaction as it is performed, including imaging reaction mixtures and obtaining Raman spectra using a camera and Raman probe attached to the synthesis platform, respectfully, as well as offline analysis of solutions via HPLC and solids via XRPD. A mobile robot will facilitate the automated refilling of consumables, the movement of HPLC vials to the instrument for analysis, and the removal of completed reactions, enabling this workflow to become truly closed-loop once the data is automatically collected and the next generation of experiments determined. To illustrate this workflow, case studies will be presented on our recent efforts to optimize cross-coupling reactions for API production, highlighting both their successes as well as the limitations of our current hardware and software tools.

Ultimately, we aim to not only present the current state of our workflow, but also the future fully-automated state that we plan to achieve. Upon fully closing the loop, this workflow will enable us to reduce the time for performing multiple generations of Bayesian Optimization-guided experimentations from typically 1-2 weeks down to only a few days by enabling data analysis and new experimentation to occur overnight and on weekends. Critically, this will increase turnaround times for our HTE team to provide meaningful data to process chemists and engineers, allowing more informed decisions to be made sooner regarding process optimization within SMPD.