2025 AIChE Annual Meeting

(428a) Self-Aligned, Additive Manufacturing Approaches to Large Area Electronics

Author

C. Daniel Frisbie - Presenter, University of Minnesota

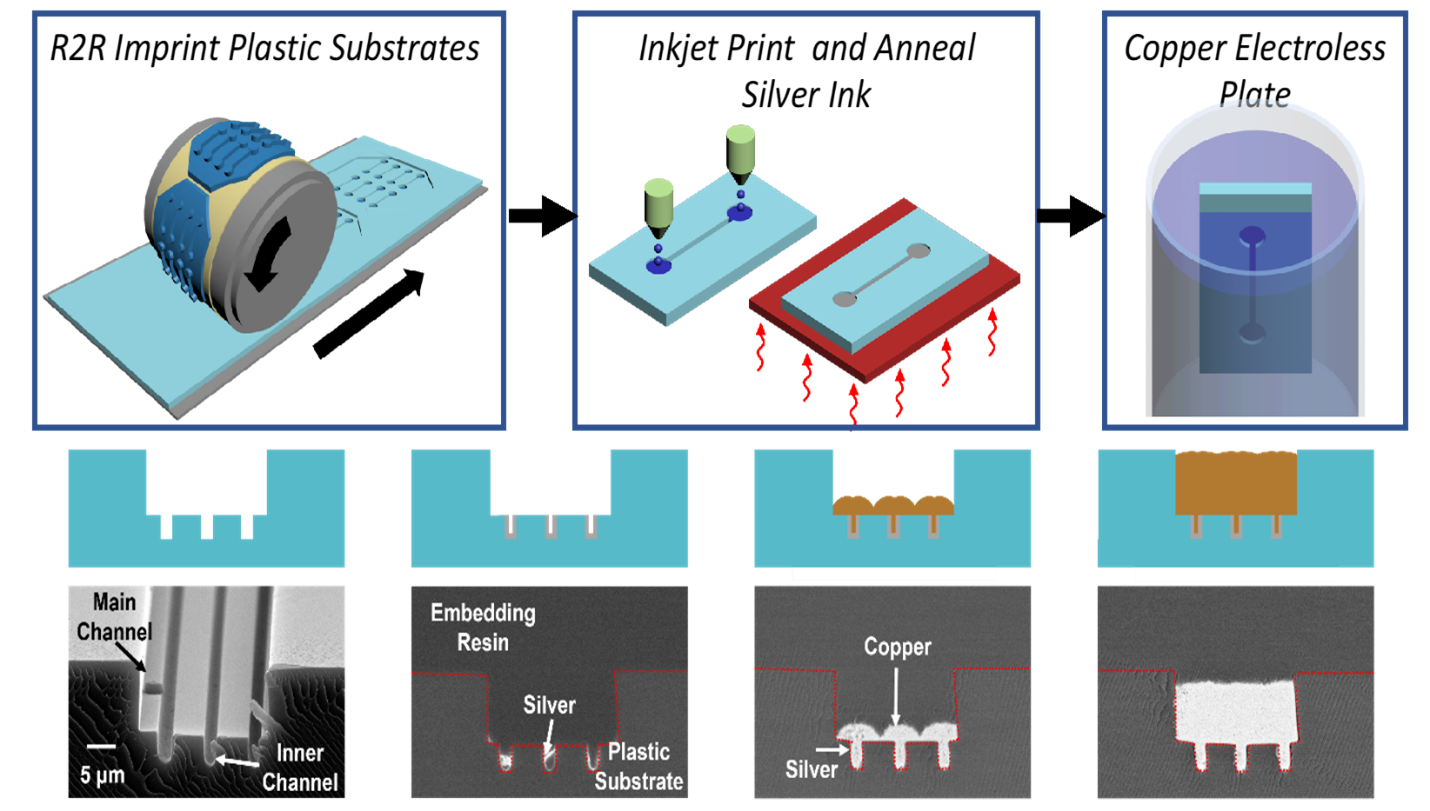

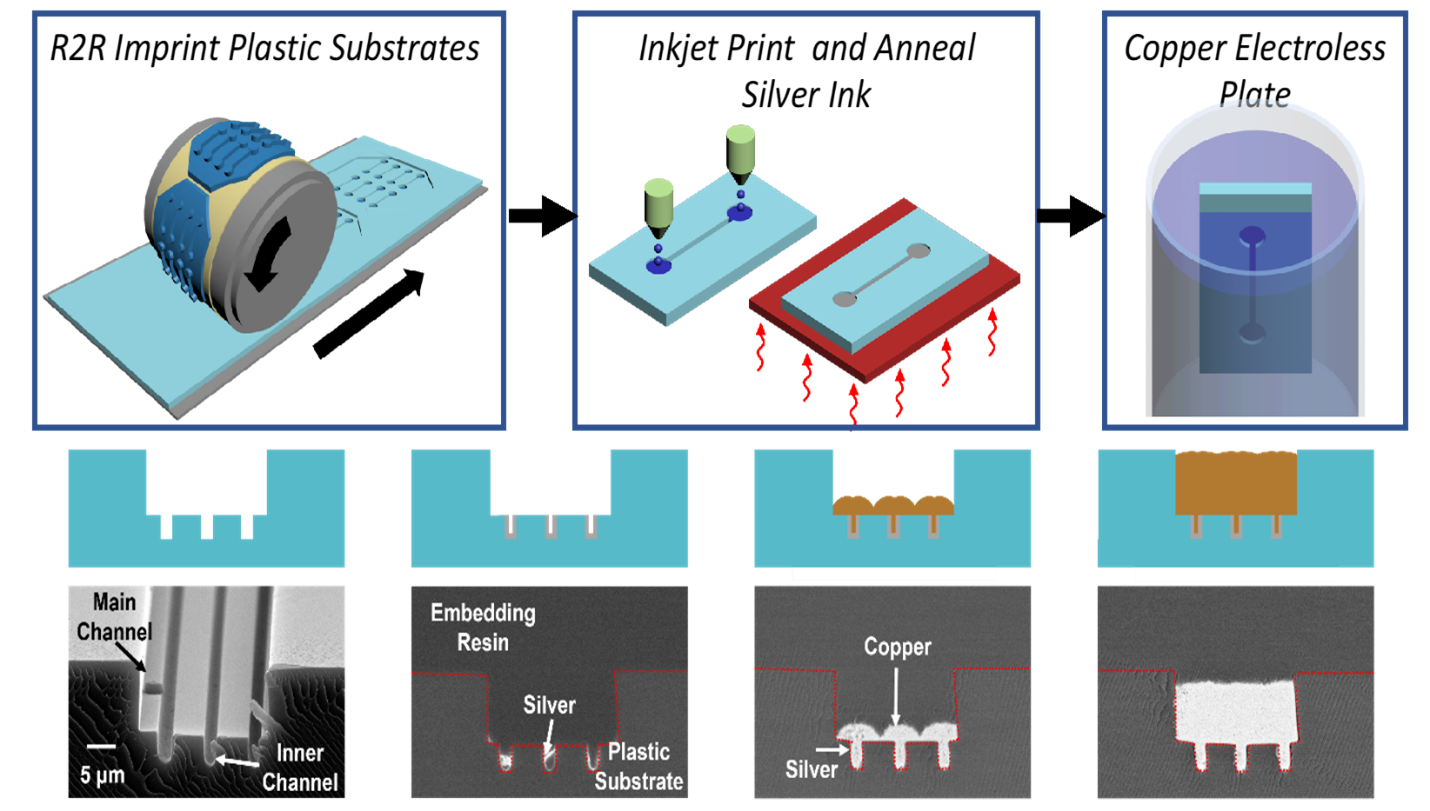

Additive manufacturing (e.g., printing) of large area electronics has a number of significant challenges, including spatial resolution, pattern registration, and printed circuit performance. This talk will describe a patented liquid-based fabrication approach developed at Minnesota (with colleague Lorraine Francis) that we term SCALE, or Self-Aligned Capillarity-Assisted Lithography for Electronics. The SCALE process combines imprint lithography with inkjet printing and plating processes to produce self-aligned devices with feature sizes that are currently as small as 2 mm. Beyond the critical self-alignment aspect, SCALE offers a number of possible advantages for large area electronics manufacture including compatibility with roll-to-roll (R2R) manufacturing, excellent spatial resolution, conventional height-to-width aspect ratios for conductor lines, and sharp, well-defined line edges of all printed features. This talk will provide an update on the use of R2R SCALE to build arrays of discrete device components including resistors, capacitors, diodes, interconnects, and transistors. As SCALE relies on capillary flow of electronic inks in imprinted features, some important fundamentals of capillary flow, and practical innovations for controlling flow, will also be covered.