2025 AIChE Annual Meeting

(152e) Selecting Optimum Side-Entry Mixer Propeller Technology across Process Viscosities to Minimize Total Cost of Ownership

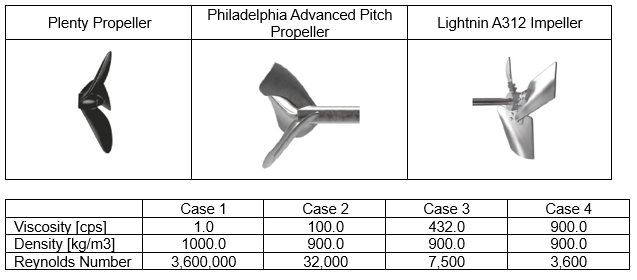

To demonstrate the principle, a CFD (computation fluid dynamics) case study was devised and executed. The tank geometry was defined as flat bottomed, cylindrical tank with a diameter (T) of 30 m [98 ft] and a liquid height (Z) of 20 m [66 ft]. The tank contained a single side entry mixer. The mixer was aimed 10 degrees left horizontally. Five propeller technologies were included in the study. The Plenty Propeller, Philadelphia Advanced Pitch (AP) Propeller, Lightnin A312, Alternative A, and Alternative B. The impeller diameter was 0.71 m [28 in] and the off-bottom of each propeller was 0.508 m [20 in].

The power input of each propeller type was held constant by varying operating speed. The densities and viscosities for the process conditions are listed in the table below as well as the calculated Reynolds number for the baseline propeller.

The results compare which impeller is most suited for the simulated viscosities. This will include visuals such as velocity contour slices and pathlines to follow flow distribution. Calculations such as pumping capacity were also calculated and will be shared.