2025 AIChE Annual Meeting

(501f) Scheduling and Control of Green Ammonia Plants

Authors

The scheduling and control problem involves the first to third layer as described in the international standard for the integration of enterprise and control systems (ISA-95) and is different from the integrated scheduling and design problem due to the limited knowledge of future energy availability. Salmon and Bañares-Alcántara (2023) conducted a receding-horizon scheduling of a green ammonia plant designed by solving a linear program considering one year of weather data. They found that the suboptimal operation due to the limited prediction horizon resulted in the storage being insufficient in many cases, requiring multiple plant shutdowns per year. The scheduling problem assumed 12–48 h of ideal power production forecasts and a linear plant model. The study by Salmon and Bañares-Alcántara (2023) underlines that the typical design optimization results in a plant that can only achieve the production target with perfect knowledge of the future availability of renewable power.

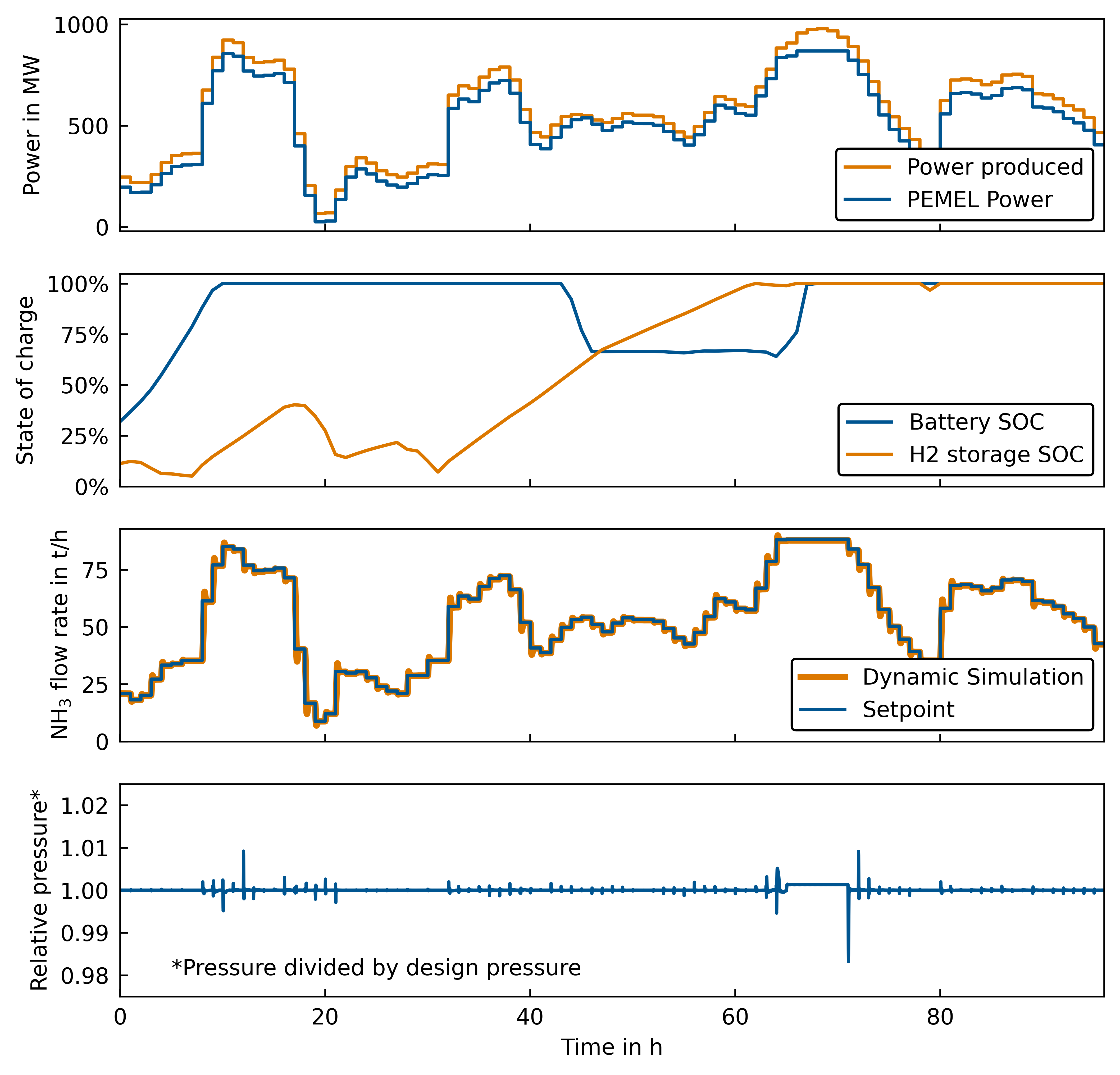

In our work, we present a novel scheduling and control framework for green ammonia plants. A plant configuration is obtained by linear-programming-based design. A detailed dynamic UniSim Design® simulation of a Haber-Bosch plant based on the one described in our previous work (FAHR 2025) is used and supplemented by simplified models of an electrolyzer and an air separation unit. The plant is operated based on the load profiles obtained from a receding-horizon linear program. Therefore, the scheduling takes place online, i.e., the inputs of the scheduling problem are given by the current state of the detailed simulation and the base control layer of the plant follows the setpoints provided by the scheduler.

By using prediction horizons on the order of 24 h, including forecast errors, and providing a detailed dynamic plant model, we present realistic operating conditions. This allows an assessment of the robustness of plants designed by linear programming in real operation and helps to draw conclusions for robust plant design.

Our results show that with suitable scheduling and realistic prediction horizons, safe operation based on renewable energy sources can be achieved without shutdowns or excessive use of backup power. At the same time, production losses due to overly conservative storage usage and additional capital expenditure for robust plant configurations are kept at a minimum.

Literature

Wang C, Walsh SDC, Longden T, Palmer G, Lutalo I, Dargaville R. Optimising renewable generation configurations of off-grid green ammonia production systems considering Haber–Bosch flexibility. Energy Convers Manage 2023; 280: 116790. http://dx.doi.org/10.1016/j.enconman.2023.116790.

Salmon N, Bañares-Alcántara R. Impact of process flexibility and imperfect forecasting on the operation and design of Haber–Bosch green ammonia. RSC Sustain 2023; 1(4): 923–37. http://dx.doi.org/10.1039/D3SU00067B.

Fahr S., Kender R., Bohn J.-P., Rehfeldt S., Peschel A., Klein H. Dynamic simulation of a highly load-flexible Haber–Bosch plant. International Journal of Hydrogen Energy 2025; 102: 1231–1242. https://doi.org/10.1016/j.ijhydene.2025.01.039.