2025 AIChE Annual Meeting

(584s) Scaling up the Height of CO2 Electrolysers Using a Falling Film Catholyte

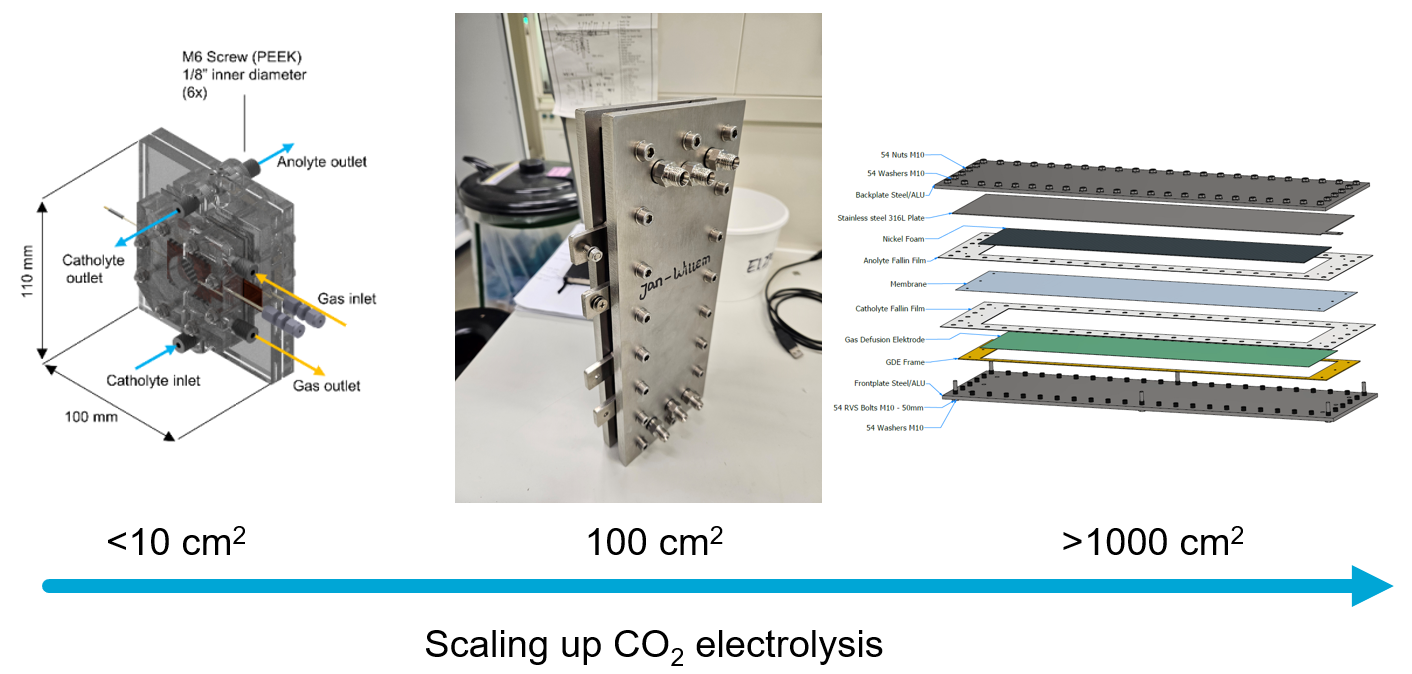

A major challenge now lies in scaling these electrolysers to industrially relevant sizes. Although GDEs enable high current densities, scaling up the active area and especially the vertical height of electrolysers introduces several complications, including GDE flooding and uneven electrolyte distribution. These limitations demand innovative design strategies to facilitate industrial-scale CO2 electrolysis.

This study proposes a novel flow cell design combining a bipolar membrane operating under reverse bias with a gravity-driven falling film catholyte compartment (Fig. attached). The falling film approach offers minimal pressure drop even for reactors taller than 1 meter, while the bipolar membrane ensures the necessary ionic environment at the cathode, even at low catholyte flow rates. The investigation comprises two main parts: (i) fluid dynamics analysis using a standalone 1 m falling film setup to determine optimal geometry, and (ii) electrochemical testing in a 100 cm2 CO2 electrolyser.