2025 AIChE Annual Meeting

(170g) Rotary 3D Printer for Additive Manufacturing of High Viscosity Filled Thermosets

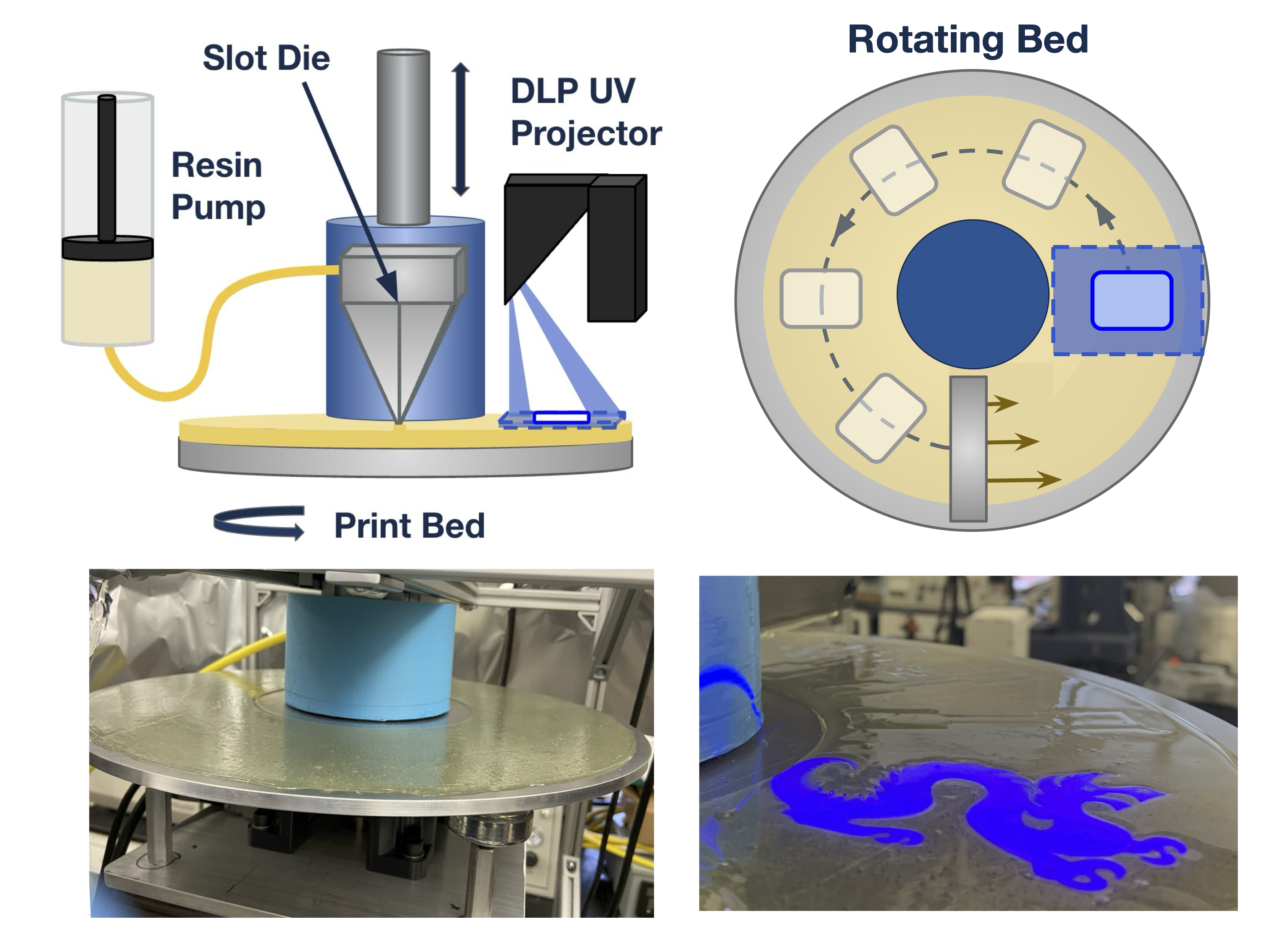

The technique combines the exposure system of a traditional DLP printer with an industrial extrusion process on a rotating build platform. The coating and printing process is continuous. The printer operates by pumping resin onto the circular build plate as it rotates along the Z axis, coating the plate with each layer. A novel slot die nozzle that is designed to apply a constant shear-rate on the extrudate, is used to form a uniform layer of the resin independent of fluid rheology. The DLP then projects a moving pattern onto the moving build platform. Current work includes modeling the layer height deposition on the circular bed and creating a working curve for the printer projection system. We will discuss several challenges of printing on a rotating bed geometry. Our findings have been developed into a slicing methodology that is validated for a wide range of print geometries. 3D profilometry is used to characterize the fluid mechanics and reaction kinetics of the printing method. The results are presented as a function of fluid rheology to determine correlations with part fidelity and quality. Overall this method moves us one step closer to user-end high-performance thermoset parts for on-demand manufacturing.