2025 AIChE Annual Meeting

(711d) Robust and Efficient Fault Diagnosis in Chemical Processes Via Model Ensemble and Neural Network Pruning

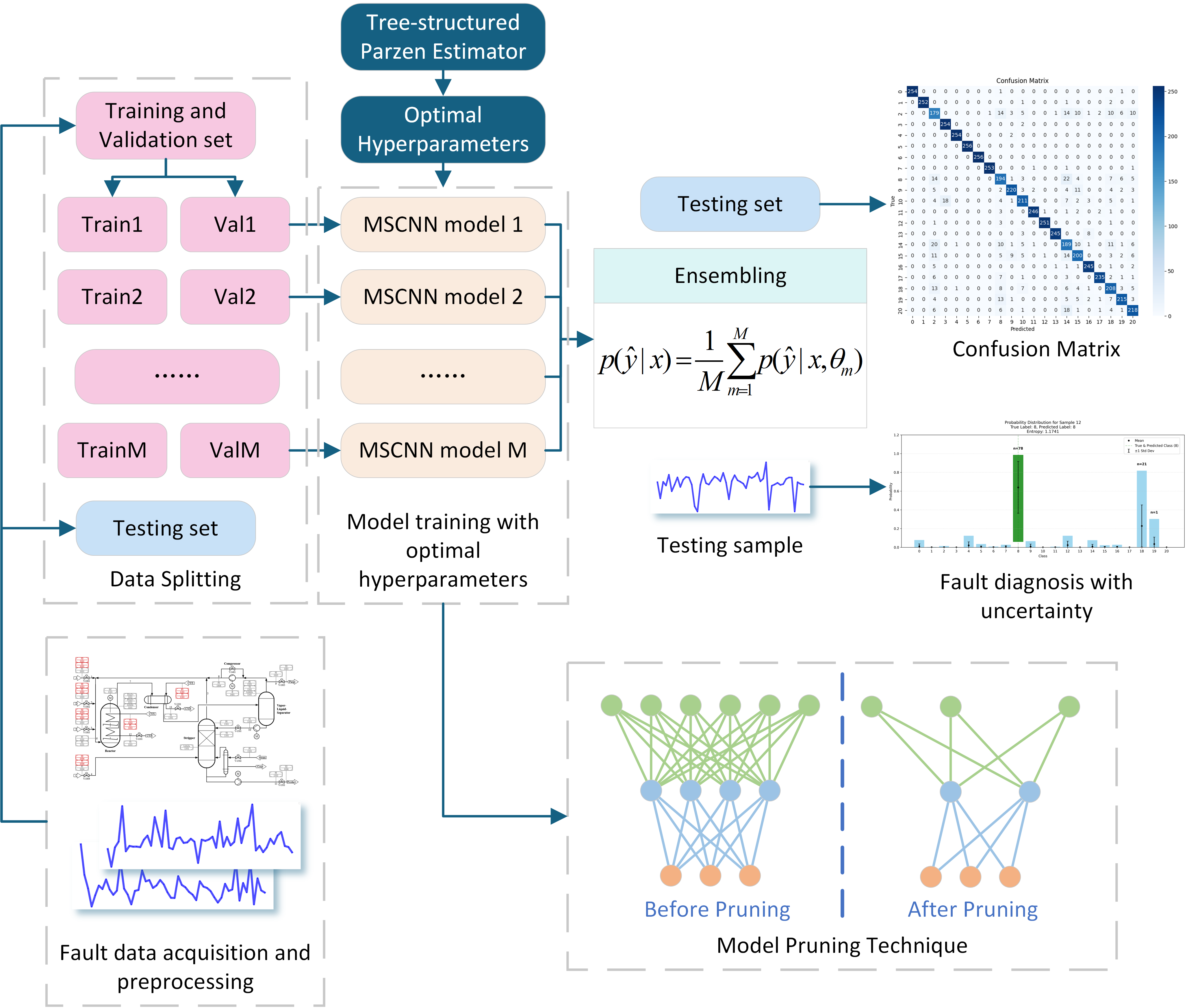

Our approach employs a multi-scale convolutional neural network (MSCNN) architecture augmented with hyperparameter optimization and model ensembling to achieve robust fault diagnosis with reliable uncertainty quantification [2]. In this study, we introduce L1-norm pruning as the final optimization step—a highly practical strategy for industrial applications [3]. By systematically pruning up to 75% of the model parameters and reducing the ensemble size from 100 to 10, we significantly lower inference latency without sacrificing diagnostic accuracy. A comprehensive sensitivity analysis is also performed to explore the trade-offs between pruning intensity, ensemble size, and overall performance, ensuring that the streamlined model remains both robust and reliable.

We validate our method using the Tennessee Eastman Process (TEP) benchmark, a widely recognized standard for chemical process fault diagnosis research. Comparative evaluations against classical methods (PCA), conventional CNNs, unpruned MSCNNs, and modern lightweight architectures (e.g., ShuffleNetV2) show that our pruned ensemble retains over 95% of the diagnostic performance of the original large-scale model while offering a substantially reduced memory footprint and improved real-time responsiveness. This work highlights the importance of integrating uncertainty estimation with latency reduction, paving the way for the practical deployment of advanced, efficient fault diagnosis systems in safety-critical industrial settings.

References:

[1] Yan, Wenhao, et al. "A review of real-time fault diagnosis methods for industrial smart manufacturing." Processes 11.2 (2023): 369.

[2] Aouichaoui, Adem RN, et al. "Uncertainty estimation in deep learning‐based property models: Graph neural networks applied to the critical properties." AIChE Journal 68.6 (2022): e17696.

[3] Kumar, Aakash, et al. "Pruning filters with L1-norm and capped L1-norm for CNN compression." Applied Intelligence 51 (2021): 1152-1160.