2025 AIChE Annual Meeting

(525c) Redefining Ammonia Synthesis Reactors – Optimal Reactor Design Considering Options for Electrical Energy Integration

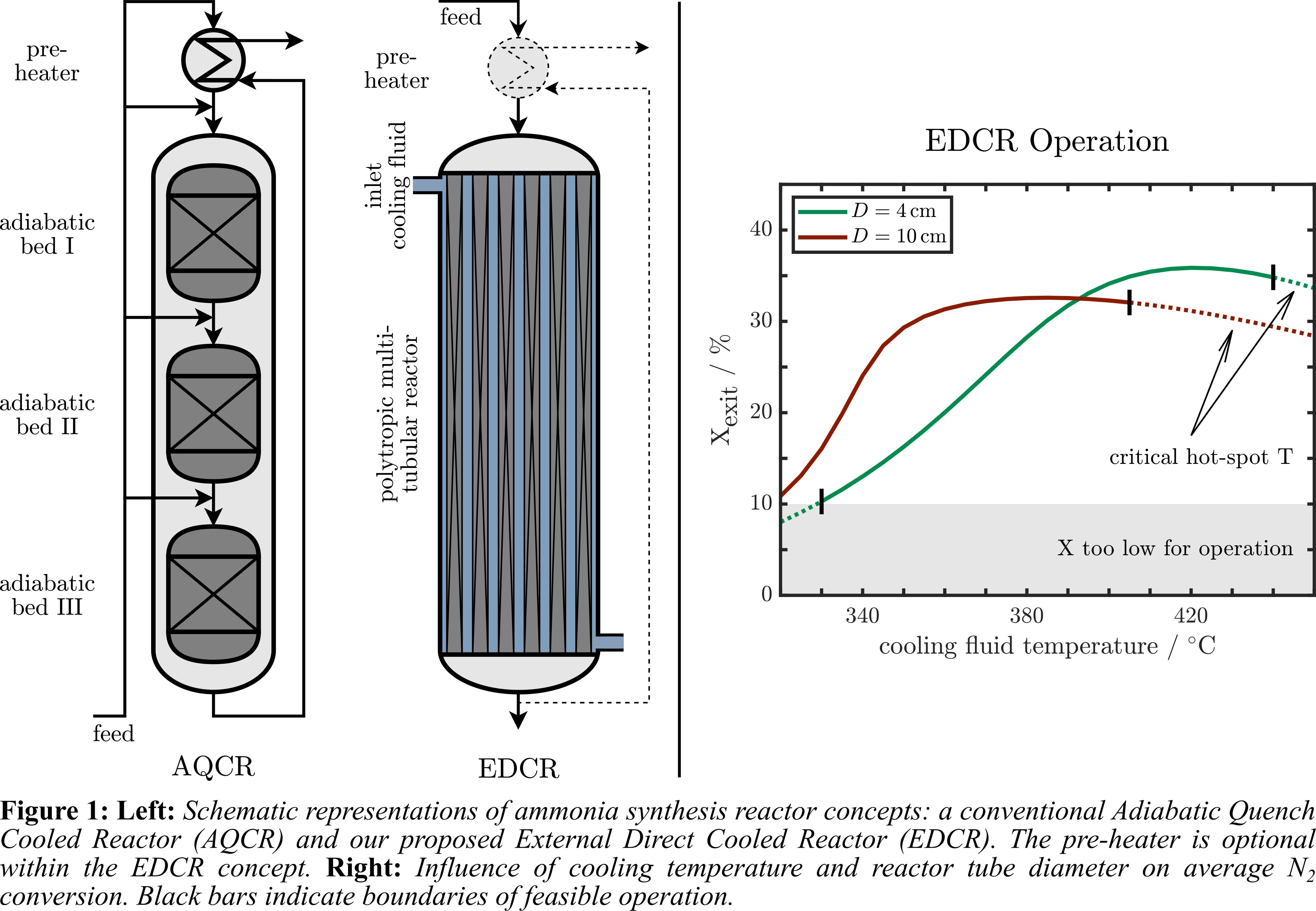

Building up on these considerations, this study focusses on determining an optimal EDCR design for load-flexible operation by detailed numerical optimization studies, including options for electrical energy integration. The EDCR is described with a two-dimensional dynamic pseudo-homogeneous reactor model. A highly active industrial iron catalyst is considered in our calculations.

Our initial EDCR design requires cooling temperatures above 380 °C for achieving high conversion rates (Figure 1, right: D = 4 cm), which is not feasible when using thermal oil as the heat transfer fluid. However, the cooling temperature can be reduced by increasing the reactor tube diameter from 4 to 10 cm (Figure 1, right: D = 10 cm). By supplying additional electric energy, cooling temperatures are further decreased and faster start-up and turn-down times are achieved. For comparison, we will also present an optimized AQCR design.