2025 AIChE Annual Meeting

(107c) Real-Time Optimization of Green Hydrogen Operations Using Digital Twins

Author

This presentation will demonstrate how modern digital twins can empower real-time optimization of green hydrogen facilities. By integrating process simulation models with real-time and predicted renewable energy data, operations teams can make informed decisions to maximize hydrogen production from a given renewable energy input. We will present a case study illustrating how optimal operating strategies adapt to varying renewable energy availability. For example, operations teams may evaluate scenarios of ramping all electrolyzers simultaneously versus individually when renewable power is limited.

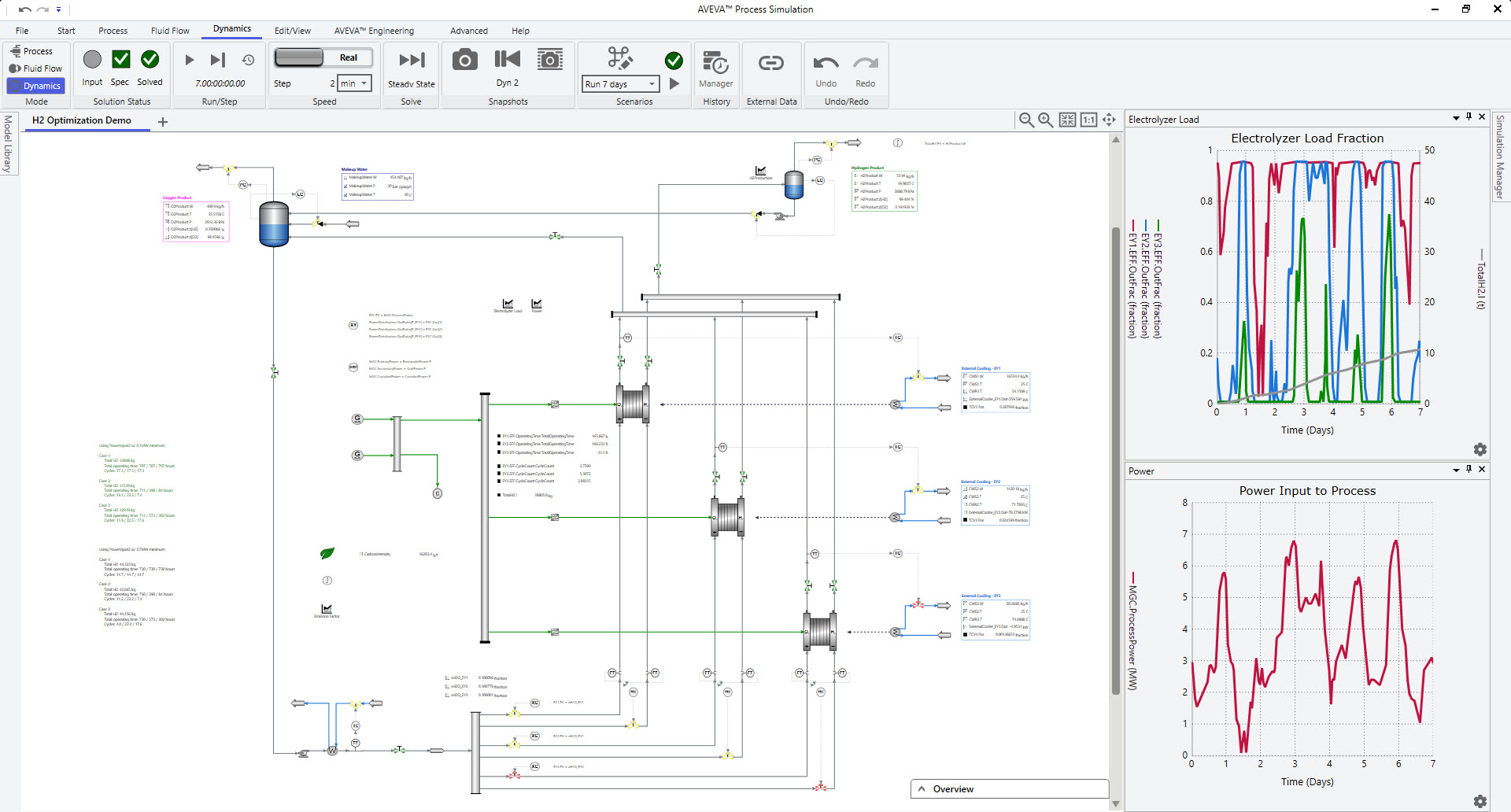

For purposes of this case study, a process simulation model of a 7.5MW Green Hydrogen facility was developed in AVEVA Process Simulation and connected to simulated real-time renewable energy data (see attached Figure). The combination of first-principles simulation and real-time data creates a Digital Twin of the process that can be used for real-time optimization of the power distribution control strategy. The simulation includes 3 parallel 2.5MW PEM electrolyzers that each have a rated Hydrogen production capacity of 45 kg/h. For real-time optimization, the simulation supports both steady-state and dynamic modeling.

Three control scenarios are studied: (1) equal ramping; (2) individual ramping; and (3) combined ramping. In the equal ramping scenario, power is split evenly between all electrolyzers. This results in all electrolyzers operating at the same load fraction regardless of the supplied power. In the second individual ramping scenario, power is divided among the electrolyzers so that only one unit is ramping up or down at a given time. When one electrolyzer has ramped fully up (to its rated power) or down (to its standby power), the next electrolyzer in the sequence will begin ramping up or down based on the available power. In the final combined ramping scenario, power to the electrolyzers is ramped uniformly until all electrolyzers are operating at 60% of load fraction - their most efficient operating point. Below 60%, the electrolyzers are ramped individually. These three control strategies represent a few of the real-world operating strategies used by Green Hydrogen producers.

In addition to total hydrogen production, other factors like electrolyzer membrane degradation must be considered. The simulation model accounts for membrane degradation by considering both total operating time and cycle count (the number of times a given unit is ramped up and down) for each electrolyzer in the plant. Together with the total hydrogen produciton, operating teams can make informed decisions about the optimal operating strategy for their plant.

Since electrolyzer efficiency varies (non-linearly) with input power, the optimal control strategy is highly dependent on the available renewable power trend. For this reason, Green Hydrogen producers must routinely re-evaluate the selected control strategy at the production facility. A connected Digital Twin model allows for fast reevaluation and optimization of the control strategy. By running the model with forecasted renewable energy data, Green Hydrogen producers will receive early information about total hydrogen production, operating time, and cycle counts for each electrolyzer at the facility using different control strategies. After evaluating all potential control strategies, plant operators can select the ideal strategy for the given period.

In this presentation, we will provide the results of this optimization for a few renewable energy input trends. At the conclusion of the presentation, we will provide practical advice to help attendees maximize their green hydrogen production and apply the optimization algorithms to their own plants.