2025 AIChE Annual Meeting

(489d) Re-Parametrization of NRTL Model for C1+ Organics and Alcohols Recovery from Aqueous Phase in Biofuel Production

Authors

In the FUEL-UP project, the aqueous phase from liquid-liquid separation with pyrolysis oil is withdrawn to recover alcohols and other relevant chemicals such as acetic and formic acid. These components are diluted inside the solvent. The resulting purification through distillation in energy demand and the thermodynamic model should be reliable to pursue energy integration and optimize of the recovery process. The Non-Random Two-Liquids (NRTL) models in both Aspen Plus and COFE V3.7, a license-free software released by AmsterChem, does not accurately reproduce the equilibrium measurements of most of the ternary mixtures involving water, a C1-C4 alcohol, namely methanol (MeOH), ethanol (EtOH), Propanol (PropOH), and n-butanol (ButOH), and a light carboxylic acid such as acetic (AcAc) and formic acid (FA). Hence, at the status, they cannot be exploited for the design and upscaling of the separation processes of organic compounds from the aqueous phase. The lack of accurate thermodynamic models is a gap in the existing literature.

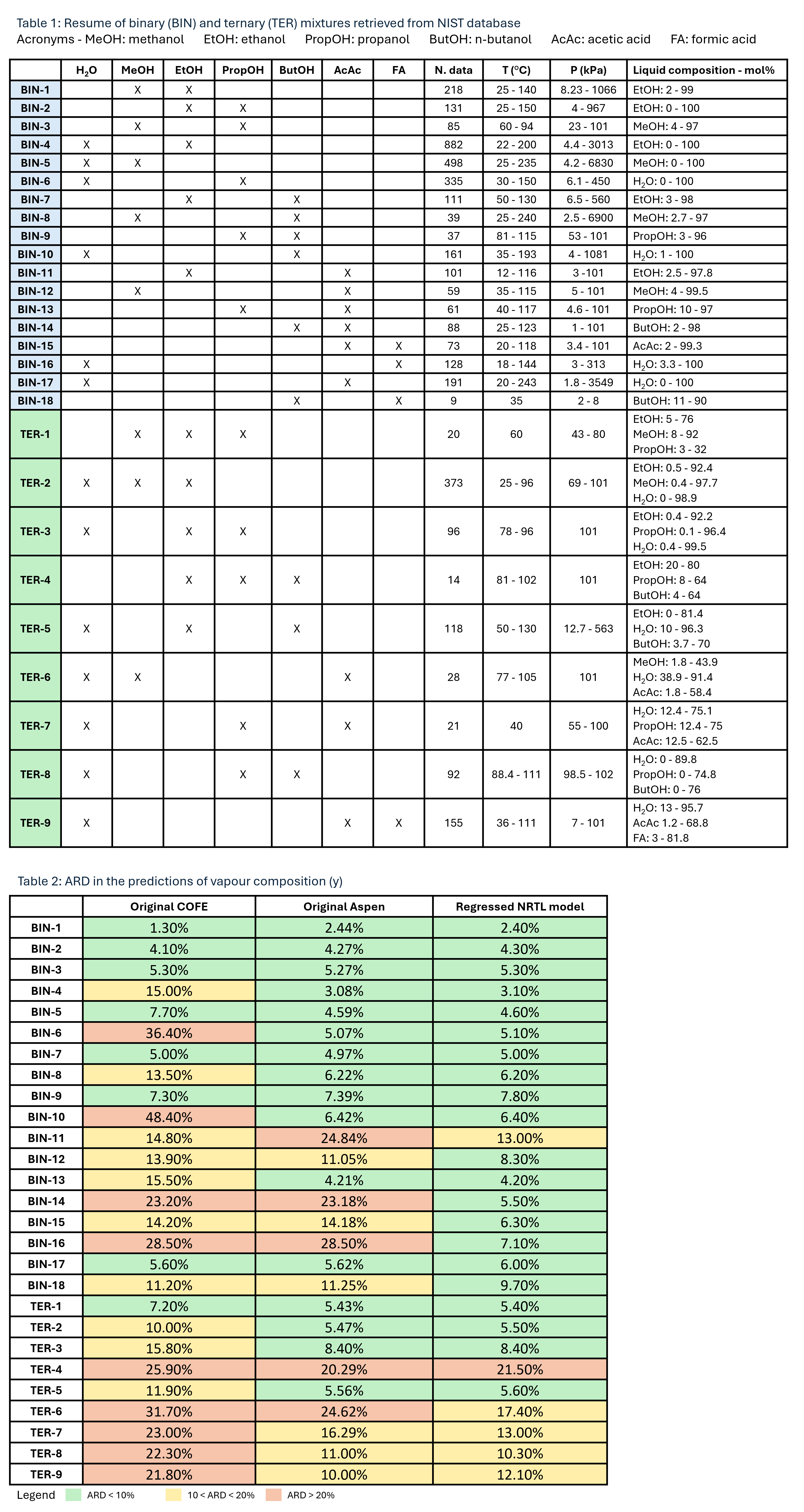

This work aims to retune the activity-based model to improve the NRTL model predictivity. The NIST database is used to retrieve all the experimental measurements for the regression of the thermodynamic model accounting for binary and ternary mixtures. Table 1 gathers and resumes the combinations of binary and ternary mixtures, the number of data available for each of those, and the covered range for temperature, pressure, and composition.

The NRTL model has been regressed in Aspen PLUS V14 using the Maximum Likelihood algorithm following the same procedure adopted in Gilardi et al. [1].

The Modified Barker’s algorithm is used for the evaluation step. For isothermal binary data temperature (T) and liquid composition (x) are fixed, while pressure (P) and vapour composition (y) are calculated based on the NRTL model. For binary isobaric data, P and x are assigned and T and y are model outputs. For ternary data, the system has an additional degree of freedom according to the Gibbs phase rule; therefore, Modified Barker’s model fixes both T and P as well as x; hence only y is calculated.

The Average Relative Deviation (ARD) and Average Absolute Deviation (AAD) for the generic variable (T, P, or y) are defined as usual

Relative and absolute deviations between experimental data and model prediction have been used to assess the model accuracy (Table 2). Detailed results will be presented at the event; here the discussion is limited to ARD for vapour composition prediction only.

The resulting re-parametrised NRTL shows improved accuracy and reliability compared to the existing models. For 78% of the considered mixtures, the ARD is below 10% and for only one mixture the ARD is kept above 20%. Remarkably, the regressed model exhibits significant improvement also compared to the Aspen PLUS model, especially for binary mixtures involving formic and acetic acid.

Acknowledgement

The present work received co-funding from FUEL-UP project, part of the European Union’s Horizon Europe Research and Innovation Programme under Grant Agreement N° 101136123

Reference

[1] M. Gilardi, F. Bisotti, A. Tobiesen, H.K. Knuutila, D. Bonalumi, An approach for VLE model development, validation, and implementation in Aspen Plus for amine blends in CO2 capture: the HS3 solvent case study, International Journal of Greenhouse Gas Control 126 (2023) 103911. https://doi.org/10.1016/j.ijggc.2023.103911.