2025 AIChE Annual Meeting

(77f) Production of Liquid Fuels Via Chemical Looping of Biomass: A Techno-Economic Comparison with Conventional Routes

Authors

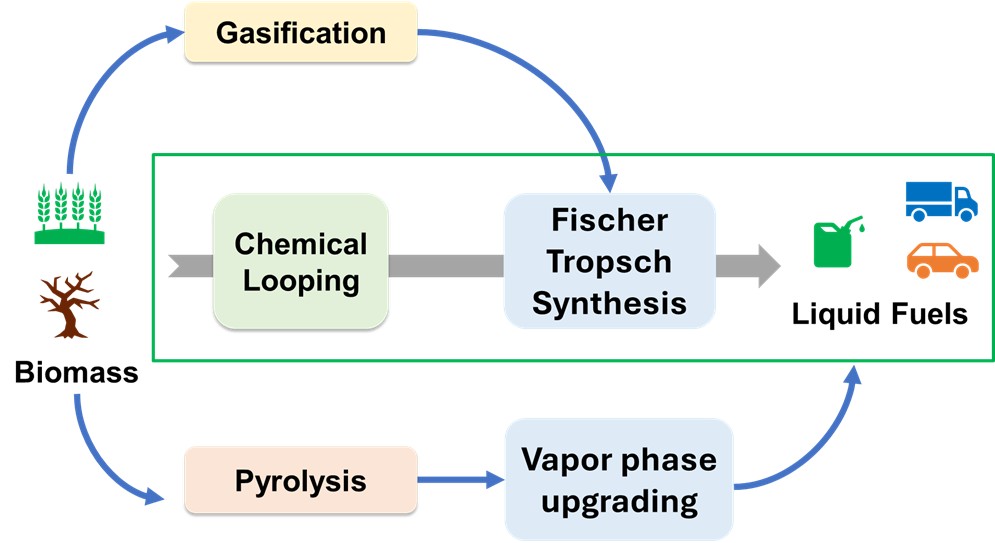

The objective of this study is to compare three pathways for producing liquid fuels from carbon-neutral feedstocks, such as biomass. The three pathways are (a) Chemical Looping Biomass-to-Syngas with Fischer-Tropsch synthesis (CLFT), (b) biomass pyrolysis with vapor-phase upgrading and hydroprocessing (PHP), and (c) biomass gasification integrated with Fischer-Tropsch synthesis (GFT). The CLFT process has been designed and modeled using ASPEN Plus, based on The Ohio State University’s moving-bed chemical looping technology. A comprehensive techno-economic evaluation is conducted, benchmarking CLFT against the PHP and GFT processes through a discounted cash flow analysis. This assessment encompasses key economic and performance indicators, including carbon and energy efficiencies, minimum fuel selling price (MFSP), capital expenditures, and operating expenditures. Furthermore, sensitivity and plant size analyses are performed to assess the influence of technical and market variables, providing insights into the adaptability and economic resilience of each pathway.

The carbon conversion efficiencies of CLFT, GFT, and PHP are estimated at 32.3%, 30.5%, and 40.4%, respectively, while their energy efficiencies are 37.7%, 37.3%, and 54.1%. A minimum fuel selling price (MFSP) analysis, conducted using a discounted cash flow approach, estimates MFSP values of $3.49 /GGE for CLFT, $5.26 /GGE for GFT, and $4.54 /GGE for PHP. Sensitivity analysis reveals that feedstock cost exerts the greatest influence on MFSP, followed by the internal rate of return and capital expenditures. Additionally, a 50% increase in plant capacity (from the baseline 2,000 dry tons/day of biomass) results in only an 11% reduction in MFSP, whereas a 50% decrease in plant size leads to a more pronounced 17% increase in MFSP.

These above findings underscore the economic and technical viability of biomass-based liquid fuel production, positioning CLFT as a particularly promising pathway due to its lower production costs thereby reinforcing its potential as a competitive alternative for sustainable fuel synthesis.