2025 AIChE Annual Meeting

(241a) Process Monitoring and Safety-Informed Control of Proton Exchange Membrane Water Electrolysis System: An Experimental Study

Authors

Yuanxing Liu,1,2,3,* Sahithi Srijana Akundi1,2,3, Austin Braniff4, Beatriz Dantas4, Shayan S. Niknezhad1, Faisal Khan2,3,**, Yuhe Tian4, Efstratios N. Pistikopoulos1,3, **

1Texas A&M Energy Institute, Texas A&M University, College Station, TX, USA

2Mary Kay O’Connor Process Safety Center (MKOPSC), Texas A&M University, College Station, TX, USA

3Artie McFerrin Department of Chemical Engineering, Texas A&M University, College Station, TX, USA

4Department of Chemical and Biomedical Engineering, West Virginia University, Morgantown, WV, USA

*Presenter E-mail: liuyuanxing@tamu.edu

**Correspondence: fikhan@tamu.edu and stratos@tamu.edu

Abstract

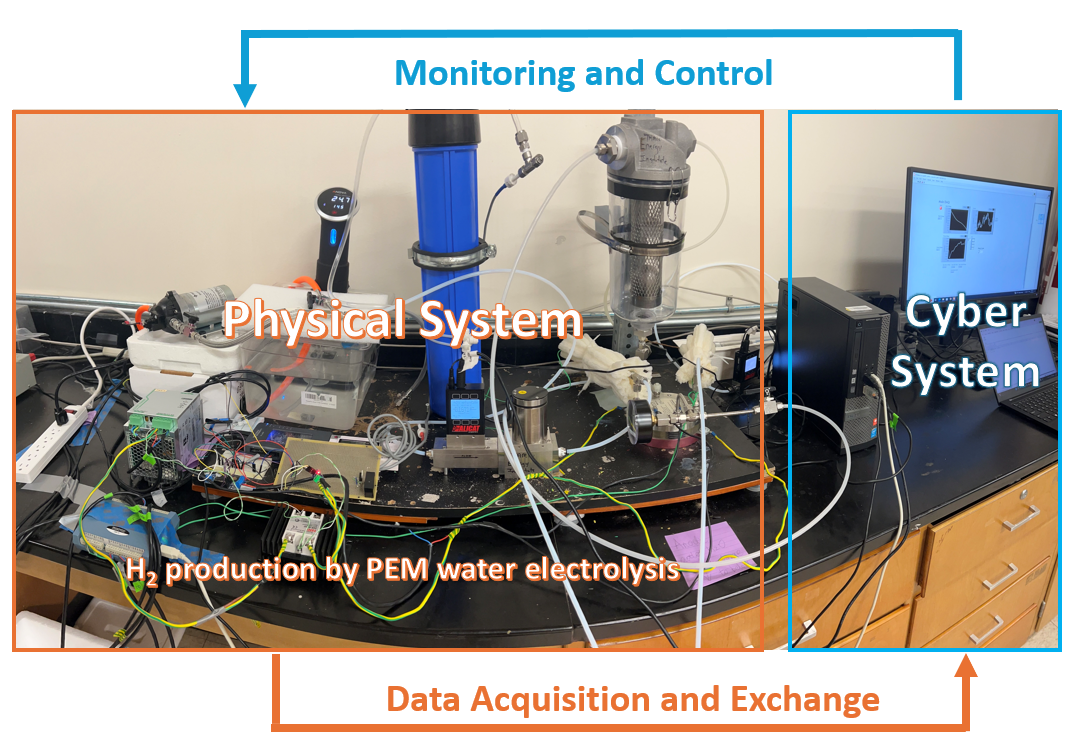

Proton exchange membrane water electrolysis (PEMWE) is a promising technology for green hydrogen production, offering high efficiency and scalability. However, the operational efficiency of PEMWE systems is hindered by the complex interplay of electrochemical, thermal, and fluid dynamic processes. This study presents an experimental investigation into the application of model predictive control (MPC) for optimizing hydrogen production and ensuring thermal stability in a PEMWE cyber -physical system as shown in Figure 1. To achieve optimal performance, the proposed control framework leverages real-time data acquisition and advanced modeling techniques to dynamically adjust system inputs, including stack current and water flow rate.

A state-space model was developed based on experimental data, which captures the system's dynamic behavior. The MPC controller is designed to minimize temperature differences across the electrolyzer stack while tracking hydrogen production setpoints. Experimental results demonstrate the controller's ability to maintain thermal stability, with temperature differences controlled within ±0.5 K, and hydrogen production rates achieving steady-state errors below 4%. The study also introduces a dynamic risk indicator (RI) to assess operational risks based on temperature deviations, providing a quantitative measure of system safety.

The results highlight the effectiveness of the MPC strategy in optimizing hydrogen production under varying operational conditions, including step changes in setpoints. The controller's ability to dynamically adjust inputs ensures efficient operation while maintaining thermal stability. This work contributes to the advancement of PEMWE technology by demonstrating the potential of advanced control strategies to enhance operational efficiency and safety. By integrating advanced control techniques with real-time process monitoring, this study provides a comprehensive approach to optimizing PEMWE systems, offering valuable insights for chemical engineers and researchers working on hydrogen production technologies.

Keywords: Process monitoring, hydrogen safety, process safety, model predictive control