2025 AIChE Annual Meeting

(302c) Process Intensification Study of the Separation of Fermenter Off-Gas Isoprene

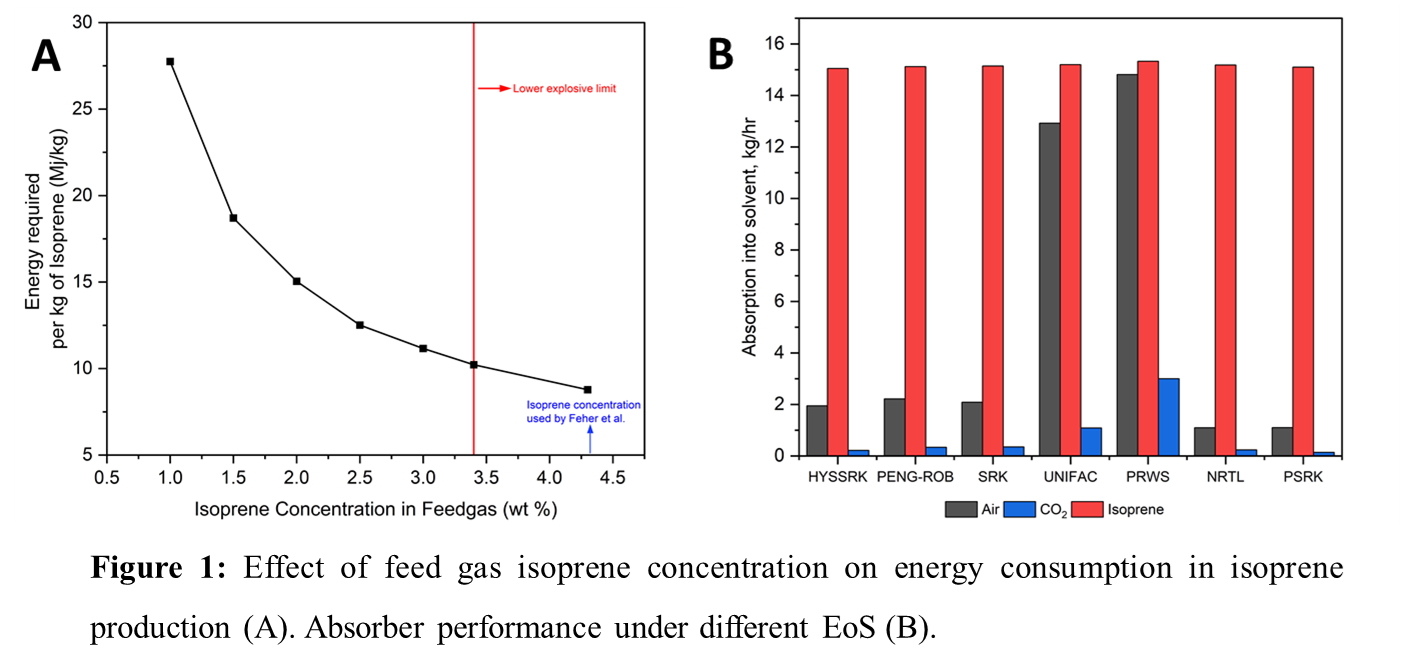

A comprehensive process simulation was developed using Aspen Plus™ to recover isoprene from an air-rich fermentation off-gas. The process integrated units like absorber, vacuum degasser, steam stripper, and separators. Multiple equations of state (EOS)—including Peng-Robinson, Soave-Redlich-Kwong, UNIFAC, NRTL, and PSRK—were evaluated for modeling vapor–liquid equilibrium. Three recycle loops—solvent, water, and isoprene vapor—were implemented to minimize material losses. Sensitivity analyses were conducted on key parameters, including feed isoprene concentration, solvent-to-feed ratio, and vacuum pressure. Energy demand decreased significantly at higher isoprene feed concentrations, along with a 34% reduction in solvent and steam usage. Compared to previous work1, this process reduced steam demand by up to 40% at similar concentrations due to optimized solvent to feed gas ratio. Vacuum degassing also enhanced isoprene recovery, preventing up to 20% loss at atmospheric pressure. Overall, >95% of isoprene was recovered from the process.

This study introduces a highly integrated, simulation-driven approach for the separation of dilute isoprene from fermentation off-gas. It provides critical insights into the influence of feed concentration and solvent flow on process economics. By leveraging advanced simulation and optimization tools, this study offers a scalable and sustainable purification strategy that could accelerate the commercialization of bio-based isoprene in the petroleum and polymer industries.

References

(1) Feher FJ, Kan JK, McAuliffe JC, et al. Purification of isoprene from renewable resources. US patent US20110178261A1. Published July 21, 2011. Accessed January 21, 2025. https://patents.google.com/patent/US20110178261A1/en