2025 AIChE Annual Meeting

(562g) Process Intensification of Novel Solvent-Looping and Stripper-Free CO2 Capture Processes for Minimizing H2 Production Cost from Steam Methane Reforming Plant

Authors

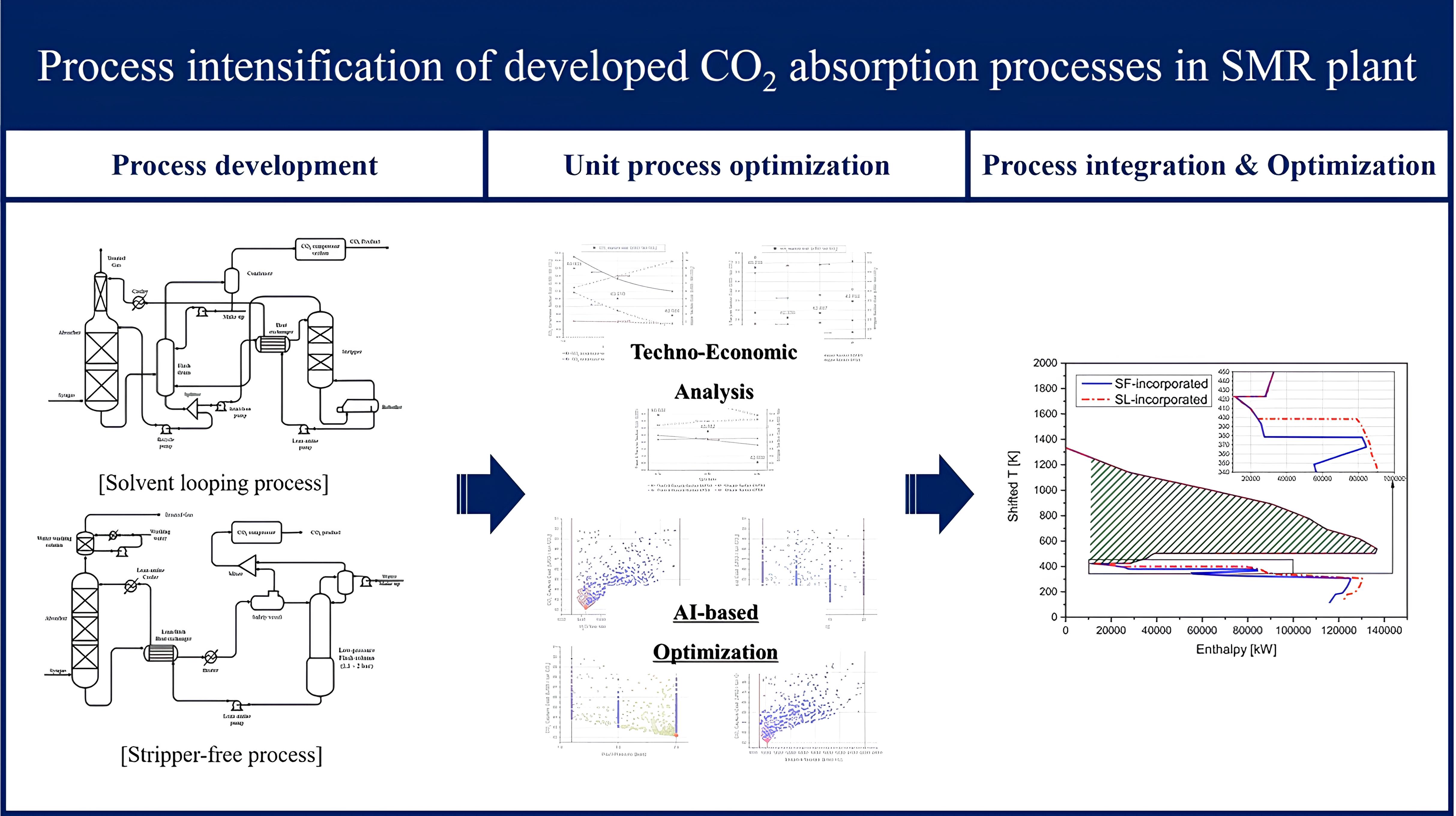

The two CO2 absorption processes were simulated using Aspen Plus V.12. For each unit process, sensitivity analysis, economic analysis, surrogate model-based optimization were conducted. In the sensitivity analysis, the effects of key operating parameters—including CO2 loading, amine concentration, flash pressure, and split ratio—were investigated. In the operating domain, 486 cases for SL process and 216 cases for SF process were simulated to generate data for developing surrogate models for SL and SF processes. Prior to surrogate modeling, feature selection was performed based on Pearson and Spearman correlation analyses, identifying four key operating parameters as modeling features. Using selected four features, surrogate models were developed to predict energy consumption and CO2 capture costs, utilizing deep neural networks and 1-D convolutional neural networks. While a simulation at a single operating condition required at least 20 minutes, the AI-based surrogate models provided prediction results in under 5 milliseconds with over 98% accuracy. The established models were then used to optimize each process, determining the optimal operating conditions that minimize CO2 capture cost and energy consumption.

In the SL process, the reboiler heat duty was significantly reduced by minimizing the flowrate directed to the stripper. The minimum reboiler heat duty was determined to be 0.622 GJ/tonCO2, with an equivalent work of 23.293 kJ/molCO2 at a 90% CO2 capture rate. Economic analysis indicated a CO2 capture cost of 43.34 USD/tonCO2. Meanwhile, the SF process offered advantages such as a simpler configuration and lower capital costs by eliminating the stripper. However, the required heat duty in the pre-flash heater was 1.881 GJ/tonCO2, and the CO2 capture cost was 45.34 USD/tonCO2. Despite its relatively high heat duty and capture cost, the SF process demonstrated significant potential for waste heat utilization due to its low regeneration temperature (below 373 K).

After evaluating the unit processes, each was integrated with the SMR reactor sector and the downstream H2 VPSA process. This integration enhanced the H2 recovery rate in the VPSA process and overall energy efficiency by utilizing waste heat from the SMR reactor sector. By cutting the CO2 in the syngas, the H2 inlet composition to the H2 VPSA process was increased, resulting in an enhanced H2 recovery rate. Furthermore, through the design of a heat exchanger network (HEN) for each integrated process, all heat duties in both SL and SF processes could be fully covered using waste heat from the SMR reactor sector.

This study proposed novel pre-combustion CO2 absorption processes using a blended amine solvent. According to sensitivity and techno-economic analyses for each unit process, the optimal operating condition and cost were identified. Additionally, through process integration, the performance of each integrated process was re-evaluated in terms of overall H₂ production cost. While the SF process exhibited lower energy efficiency with respect to a unit process evaluation, its relatively higher heat duty was fully supplied by the waste heat generated from the SMR reactor sector when integrated into the overall SMR plant. Considering its simple configuration and lower electricity consumption, the SF process had a great potential as a pre-combustion CO2 capture process for a SMR plant. These findings contribute to advancements in centralized H₂ production and CO2 capture technologies.

References

[1] Kum J, Oh H T, Park J, Kang J H, Lee C H. Techno-economic analysis and optimization of a CO2 absorption process with a solvent looping system at the absorber using an MDEA/PZ blended solvent for steam methane reforming. Chem Eng J 2023;455:140685. https://doi.org/10.1016/j.cej.2022.140685.

[2] Kum J, Cho S, Ko Y, Lee C H. Blended-amine CO2 capture process without stripper for high-pressure syngas. Chem Eng J 2024;486:150226. https://doi.org/10.1016/j.cej.2024.150226.