2025 AIChE Annual Meeting

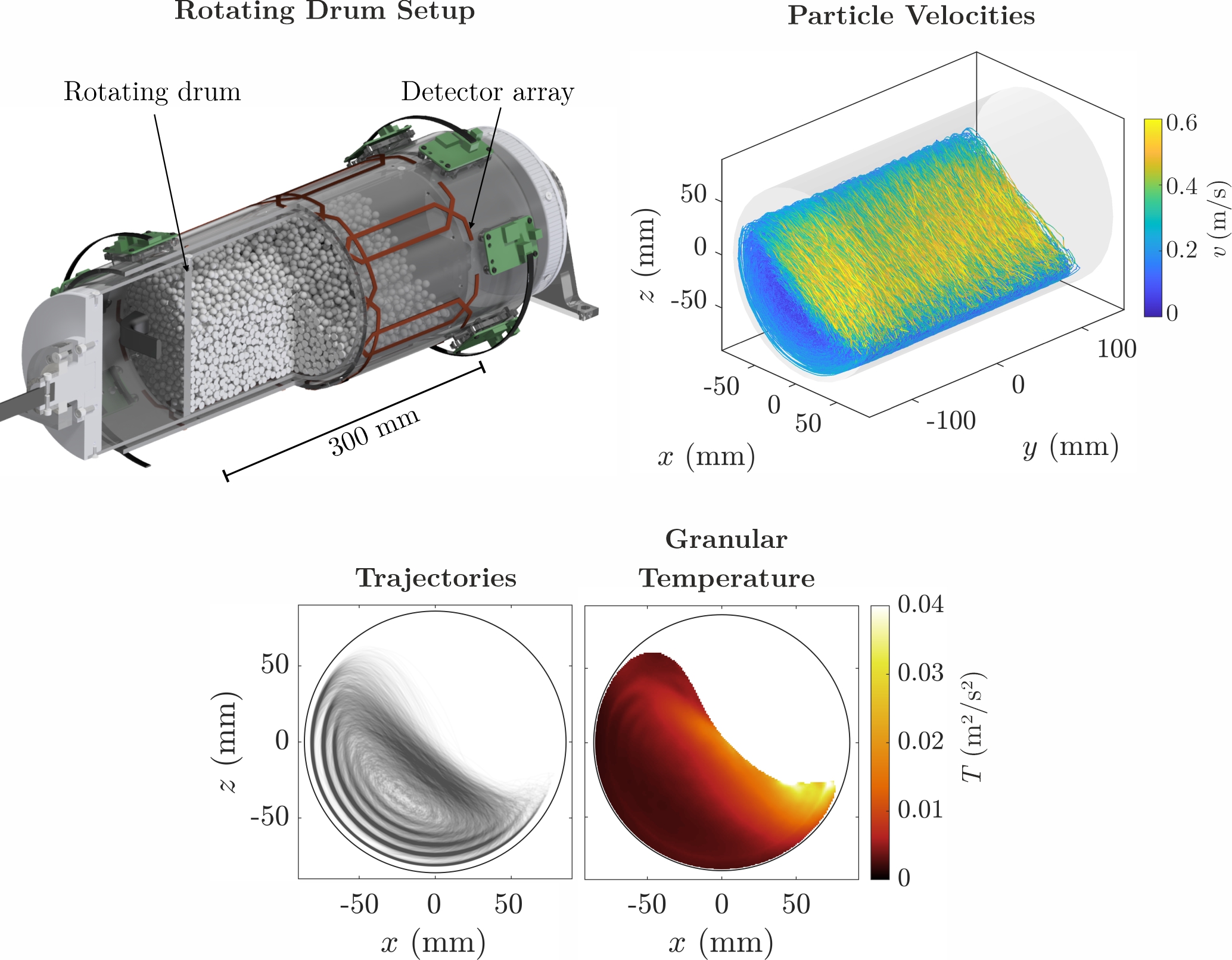

(293h) Probing 3D Particle Dynamics in a Rotating Drum By Magnetic Resonance Particle Tracking to Refine Mixing Models

Authors

The opacity of granular materials impedes the visual observation of three-dimensional (3D) particle motion in such devices. Tomographic techniques such as magnetic resonance imaging can be used as a natural alternative to optical means.5 However, they come at the cost of long acquisition times and without the ability to observe individual particle motion.3 To overcome these limitations, a novel technique referred to as Magnetic Resonance Particle Tracking (MRPT) has been introduced recently.6 MRPT enables the measurement of multiple particle trajectories in three-dimensional granular systems at a spatiotemporal resolution of a few micrometers and milliseconds.

In this work, MRPT is employed to track the dynamics of particles in a rotating drum operated in a variety of regimes (avalanching, rolling, cataracting). The high spatiotemporal resolution of the obtained trajectories allows for spatially resolved measurements of the local occupation probability of particles, the mean solid velocity and the granular temperature enabling the identification of areas in which mixing occurs. Furthermore, the probing of particle trajectories reflects partial crystallization of particle layers in the solid body of the drum. The transition probabilities between such layers are statistically analyzed to investigate the Markov property of the particle motion, providing valuable input for the refinement of mixing models.7

References

1. Boateng AA. Rotary kilns: transport phenomena and transport processes: Butterworth-Heinemann; 2015.

2. Ottino JM, Khakhar DV. Mixing and Segregation of Granular Materials. Annu Rev Fluid Mech. 2000;32(1):55-91.

3. Nadeem H, Heindel TJ. Review of noninvasive methods to characterize granular mixing. Powder Technology. 2018;332:331-350.

4. Jain N, Ottino JM, Lueptow RM. An experimental study of the flowing granular layer in a rotating tumbler. Physics of Fluids. 2002;14(2):572-582.

5. Nakagawa M, Altobelli SA, Caprihan A, Fukushima E, Jeong EK. Non-invasive measurements of granular flows by magnetic resonance imaging. Experiments in Fluids. 1993;16(1):54-60.

6. Suter M, Metzger JP, Port A, Müller CR, Pruessmann KP. Magnetic Resonance Particle Tracking. arXiv:2503.22425. 2025.

7. Berthiaux H, Mizonov V. Applications of Markov Chains in Particulate Process Engineering: A Review. The Canadian Journal of Chemical Engineering. 2004;82(6):1143-1168.