2025 AIChE Annual Meeting

(510e) Predictive Modeling of Hydrogen YIELD from Biomass-Derived BIO-Oils Using Machine Learning

Authors

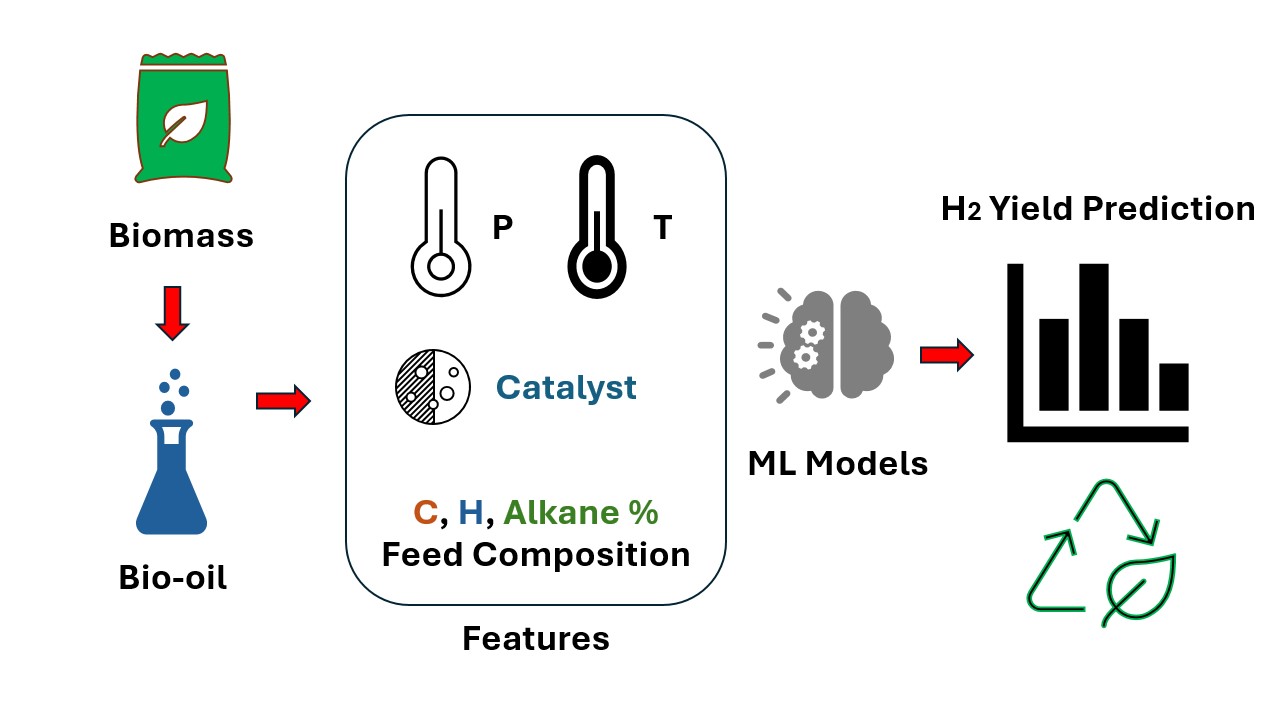

With growing interest in sustainable hydrogen production, accurate prediction of hydrogen yield

from biomass-derived bio-oils is essential for process optimization. This study develops machine

learning models to estimate hydrogen yield from a bio-oil’s composition, operating conditions,

and catalyst types, including features from cataloged experiments such as C and H elemental

composition, alkane content, temperature, pressure, catalyst type, liquid feed concentration,

contact time, and conversion rate. The dataset comprises over 100 entries. Feature preprocessing

steps included normalization and encoding of categorical features, as well as multicollinearity

checks. Several regression algorithms were tested, including Random Forest, Support Vector

Regression, and Artificial Neural Networks. For model evaluation, R², MAE, and RMSE were

calculated. The preliminary outcomes showed remarkable accuracy, with Random Forest yielding

the best results in dealing with non-linear dependencies. This work proves the efficacy of data

based methods for decision processes in biohydrogen production systems, especially for

optimizing catalyst/feedstock configurations for improved yield.

1. INTRODUCTION

Hydrogen derived from biomass offers a renewable alternative to fossil fuel-based production,

with potential environmental benefits (Balat, 2010). Various thermochemical and biological

pathways exist for biomass-to-hydrogen conversion, including pyrolysis, gasification, and

fermentation (Buffi et al., 2022). Thermochemical routes, such as steam reforming of bio-oils, are

more mature and efficient, while biological methods are still developing but offer decentralized

production options (Copa Rey et al., 2024). A two-stage process involving fast pyrolysis followed

by catalytic steam reforming of bio-oil fractions has been proposed as an economically viable

approach (Czernik et al., 2008). Some biomass-to-hydrogen technologies, like anaerobic digestion

and conventional gasification, show promise in terms of cost-effectiveness, with production costs

potentially comparable to natural gas steam reforming (Copa Rey et al., 2024). Overall, hydrogen

from biomass presents a sustainable option to complement electrolysis-based production and

contribute to decarbonization efforts (Buffi et al., 2022).

Machine learning (ML) has emerged as a powerful tool for optimizing biohydrogen production

from biomass and agricultural waste. ML algorithms can effectively model complex relationships

between operational parameters and process performance, predict outcomes, and analyze

microbial population dynamics (Pandey et al., 2022; Sharma et al., 2022). These techniques have

been applied to both biochemical and thermochemical conversion processes, demonstrating the

ability to handle large datasets and adapt to changing conditions (Alagumalai et al., 2023). ML

approaches have shown success in categorizing and predicting biohydrogen production data, with

various algorithms exhibiting high accuracy (Alagumalai et al., 2023). Additionally, ML has been

used to predict bio-oil yield and hydrogen content based on biomass composition and pyrolysis

conditions (Tang et al., 2020). Despite its potential, challenges remain in implementing ML for

large-scale biohydrogen production, including techno-economic barriers and the need for further

research to develop reliable process control tools (Pandey et al., 2022; Sharma et al., 2022).

This study aims to apply ML techniques to predict the hydrogen yield (expressed as mol/mol C)

from bio-oil gasification and reforming experiments. The analysis is based on a structured dataset

with parameters related to feed composition, catalyst type, reaction temperature and pressure, and

process metrics such as conversion and selectivity.

2. MATERIALS AND METHODS

2.1 Dataset

The dataset contains 100+ records of experimental data involving hydrogen production from

various bio-oil samples. Each entry includes:

Feedstock properties: Carbon and hydrogen content, alkane fraction

Process conditions: Temperature (°C), pressure (atm), contact time (min)

Catalyst information: Catalyst composition (e.g., 3% Pt/Al₂O₃ variants)

Performance metrics: Conversion rate (%), CH₄ yield, H₂ selectivity, and hydrogen yield

(mol/mol C)

2.2 Data Preprocessing

Missing values and anomalies were checked and addressed.

Catalyst types and liquid feed compositions were encoded using one-hot encoding.

Numerical features were standardized for uniform model input.

Correlation analysis was performed to reduce multicollinearity.

2.3 Modeling

Several regression models were developed and compared:

Random Forest Regressor

Support Vector Regressor

Multi-Layer Perceptron (Neural Network)

Model training and validation were conducted using k-fold cross-validation (k=5). Performance

metrics used include R², Mean Absolute Error (MAE), and Root Mean Squared Error (RMSE).

3. RESULTS AND DISCUSSION

Among the models tested, the Random Forest Regressor achieved the highest prediction accuracy,

followed by the MLP. Non-linear models outperformed linear regression approaches due to the

complex relationships between reaction variables and hydrogen yield.

Feature importance analysis indicated that temperature, pressure, and catalyst type significantly

influence hydrogen production. Notably, catalyst variants with different Pt/Al₂O₃ formulations

showed strong effects on both conversion and selectivity, which were effectively captured by the

trained models.

The findings support the use of ML as a complementary approach to experimental research,

providing fast and interpretable insights into biohydrogen systems. The models can also be adapted

for screening new feedstocks and catalyst systems.

4. CONCLUSIONS

Machine learning can effectively model the hydrogen yield from biomass-derived bio-oils by

learning from prior experimental data. These predictive models offer a practical tool for screening

optimal reaction conditions and catalyst formulations without the need for exhaustive experimental

trials. Future work will focus on expanding the dataset and integrating mechanistic constraints to

improve extrapolation capabilities.

References:

1. Alagumalai, A., Devarajan, B., Song, H., Wongwises, S., Ledesma-Amaro, R., Mahian, O.,

Sheremet, M., & Lichtfouse, E. (2023). Machine learning in biohydrogen production: a review.

Biofuel Research Journal, 10(2), 1844–1858. DOI: 10.18331/brj2023.10.2.4

2. Balat, M. (2010). Thermochemical routes for biomass-based hydrogen production. Energy Sources

Part a Recovery Utilization and Environmental Effects, 32(15), 1388–1398. DOI:

10.1080/15567030802706796

3. Buffi, M., Prussi, M., & Scarlat, N. (2022). Energy and environmental assessment of hydrogen

from biomass sources: Challenges and perspectives. Biomass and Bioenergy, 165, 106556. DOI:

10.1016/j.biombioe.2022.106556

4. Czernik, S., French, R., Feik, C., & Chornet, E. (2001). Production of Hydrogen from Biomass

Derived Liquids. Progress in Thermochemical Biomass Conversion, 1577–1585. DOI:

10.1002/9780470694954.ch130

5. Pandey, A. K., Park, J., Ko, J., Joo, H., Raj, T., Singh, L. K., Singh, N., & Kim, S. (2022). Machine

learning in fermentative biohydrogen production: Advantages, challenges, and applications.

Bioresource Technology, 370, 128502. DOI: 10.1016/j.biortech.2022.128502

6. Rey, J. R. C., Mateos-Pedrero, C., Longo, A., Rijo, B., Brito, P., Ferreira, P., & Nobre, C. (2024).

Renewable Hydrogen from Biomass: Technological Pathways and Economic Perspectives.

Energies, 17(14), 3530. https://doi.org/10.3390/en17143530

7. Sharma, A. K., Ghodke, P. K., Goyal, N., Nethaji, S., & Chen, W. (2022). Machine learning

technology in biohydrogen production from agriculture waste: Recent advances and future

perspectives. Bioresource Technology, 364, 128076. DOI: 10.1016/j.biortech.2022.128076

8. Tang, Q., Chen, Y., Yang, H., Liu, M., Xiao, H., Wu, Z., Chen, H., & Naqvi, S. R. (2020).

Prediction of bio-oil yield and hydrogen contents based on machine learning method: effect of

biomass compositions and pyrolysis conditions. Energy & Fuels, 34(9), 11050–11060. DOI:

10.1021/acs.energyfuels.0c01893