2025 AIChE Annual Meeting

(43c) Poly(Isoprene)-Block-Poly(Ethylene Oxide) Block Polymer-Toughened Polylactide

Authors

Jonathan Coote - Presenter, The University of Tennessee

Matthew Larson, University of Minnesota

Frank S. Bates, University of Minnesota

Christopher Ellison, University of Minnesota

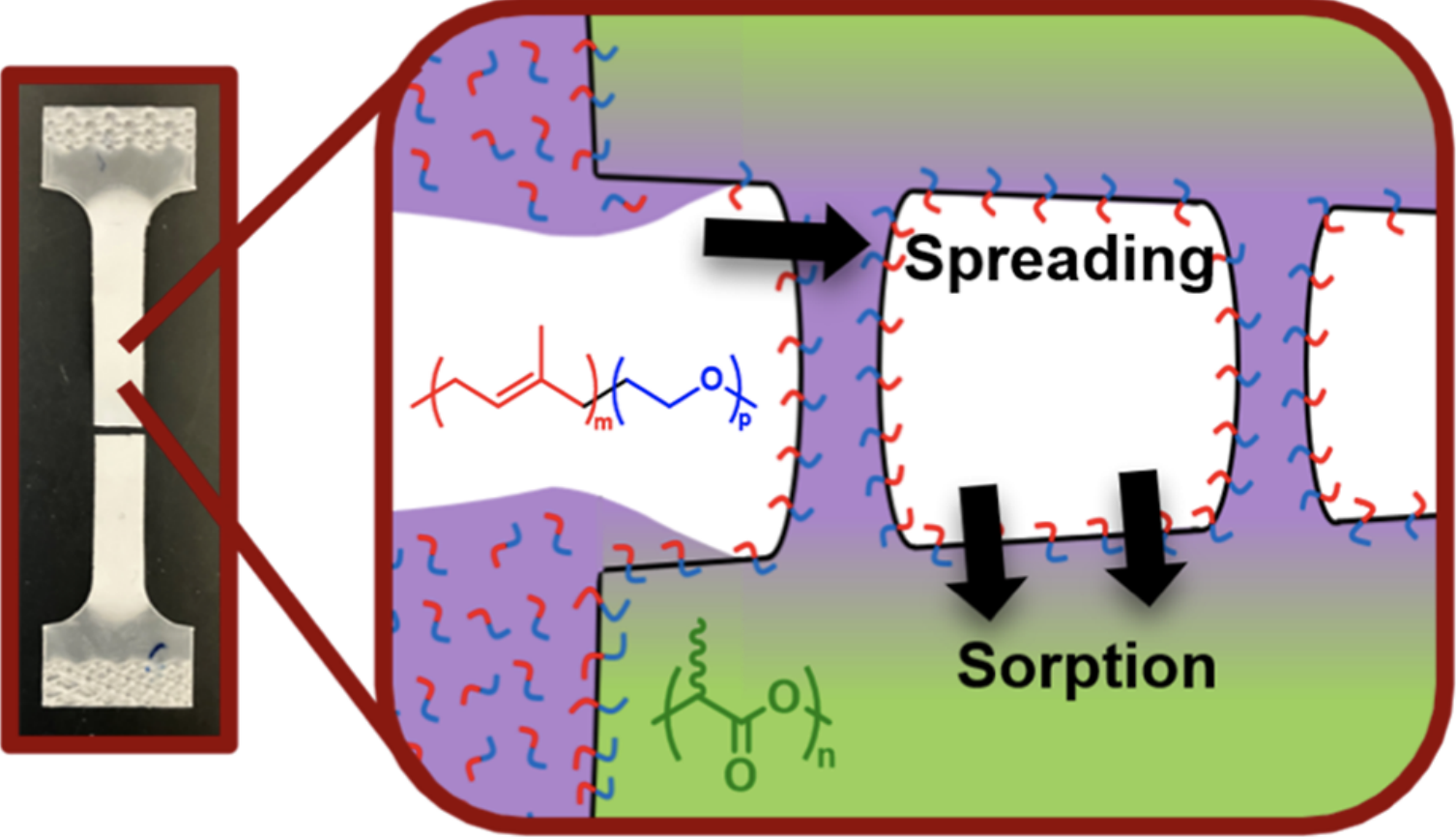

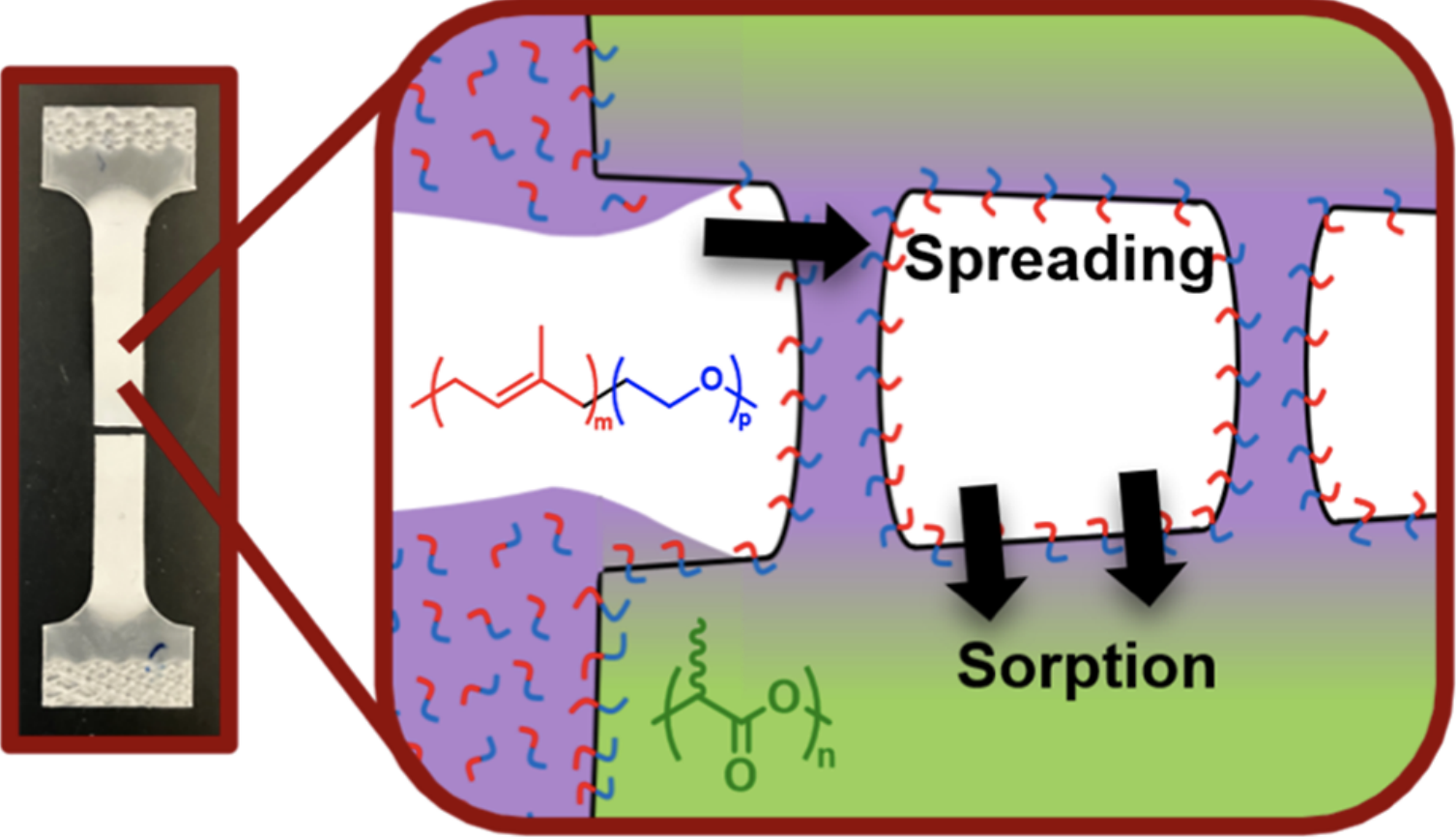

Poly(lactide) (PLA) is the most commercially successful bioderived polymer, but its brittleness, which develops within a day of aging at room temperature, limits its applications. This work explores the use of low molecular weight poly(isoprene)-block-poly(ethylene oxide) (IO) diblock polymers as toughening agents for PLA. When melt-blended with PLA, IO diblocks form submicron-scale macrophase-separated domains in the PLA matrix, stabilized by the compatibility of poly(ethylene oxide) blocks with PLA. IO diblocks with molecular weights near the room temperature order-to-disorder transition (1.7–3.3 kg/mol) dramatically enhance toughness, achieving strains at break exceeding 150%, persistent for at least nine days of room temperature aging. Higher molecular weight IO diblocks, however, do not provide the same benefits. We propose that the mechanism of improved toughness arises from two key phenomena: (1) optimal particle sizes promoting cavitation and craze initiation under stress and (2) IO draining into growing crazes, stabilizing their porous structure. Supporting experiments with poly(isoprene) homopolymers further validate this hypothesis. These findings highlight a generalizable strategy for designing block copolymer additives to improve the toughness of brittle plastics, offering new possibilities for sustainable polymer applications.