2025 AIChE Annual Meeting

(401t) Polyamide Thin-Film Composite Membranes for Gas Separations

Authors

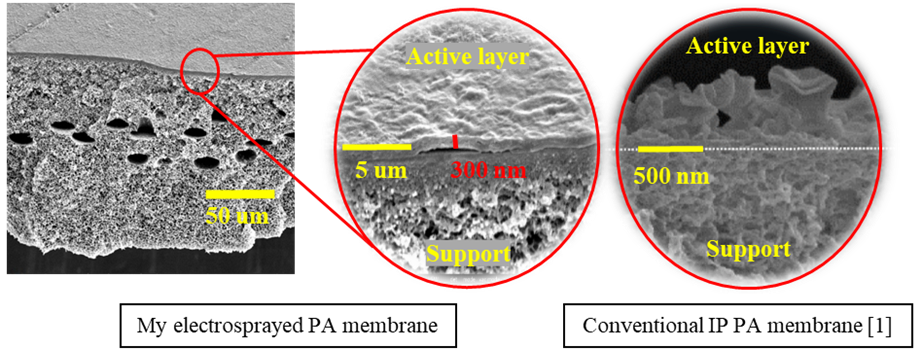

Inorganic materials like carbon molecular sieves and zeolites, as well as glassy polymers like polyimides, polyamides, polymers of intrinsic microporosity (PIMs), and block copolymers, have been widely explored. Polyamides, despite their extensive use in reverse osmosis (RO), have been surprisingly utilized in gas separation membranes. The recent study [1] on tighter polyamide membranes highlights the considerable potential of structural tuning for enhanced gas separation performance. By introducing modifications to interfacial polymerization (IP) that reduce the free volume and increase the crosslinking density of the polymer network, the defects and interchain spacing are minimized. Therefore, they hinder the passage of larger or less diffusive molecules while allowing smaller, more permeable species to maintain their transport. Traditional IP often faces several drawbacks, including uncontrolled reaction kinetics, non-uniform film thickness (shown in Figure 1), high roughness, and excessive use of hazardous organic solvents. This method typically involves the diffusion of reactive monomers at the interface of two immiscible solutions, which can lead to thicker, defect-prone membranes.

In contrast, electrospray offers significant advantages by employing a high-voltage electric field to atomize polymer solutions into fine droplets, facilitating the deposition of an ultrathin and uniform polyamide layer with precise control over thickness and microstructure with tailored properties (Figure 1). Additionally, this technique enables the use of more benign solvents, thereby reducing environmental and health risks and aligning with regulatory pressures for sustainable manufacturing practices. In this work, due to the mentioned electrospray’s advantages, we focus on the fabrication of polyamide membranes through an electrospray process to enhance gas separations. We demonstrate that the resulting membranes exhibit enhanced selectivity compared to conventional RO polyamides, with the potential to further tune permeance and selectivity through strategic monomer selection and concentrations.

The results demonstrate that electrosprayed polyamide membranes, when surface-coated with Polydimethylsiloxane (PDMS), exhibit significantly enhanced selectivity due to improved defect coverage. By optimizing the PDMS concentration, we effectively minimized non-selective defects while maintaining gas permeance. Additionally, systematic variation of the amine-to-acyl ratio, monomer concentrations, and selective layer thickness allowed precise tuning of membrane performance. Furthermore, we optimized key electrospray parameters, including voltage, spray rate, and tip-to-drum distance, to achieve uniform PA membranes. Fine-tuning these parameters enabled precise control over the polyamide layer morphology, leading to improved gas separation characteristics. These modifications highlight the potential of electrosprayed polyamide membranes for CO₂ capture and hydrogen purification.

Figure 1. SEM images of my electrosprayed PA membrane (left side) compared to conventional interfacial polymerized PA membrane reported in [1] (right side).

[1]. Z. Ali, et. al.,"Gas separation and water desalination performance of defect-free interfacially polymerized para-linked polyamide thin-film composite membranes, Journal of Membrane Science, 2021(618), 118572.