2025 AIChE Annual Meeting

(681c) Physics-Informed Inverse Design of Hexagonal Composite and Aluminium Structures for Crashworthiness Optimization

Authors

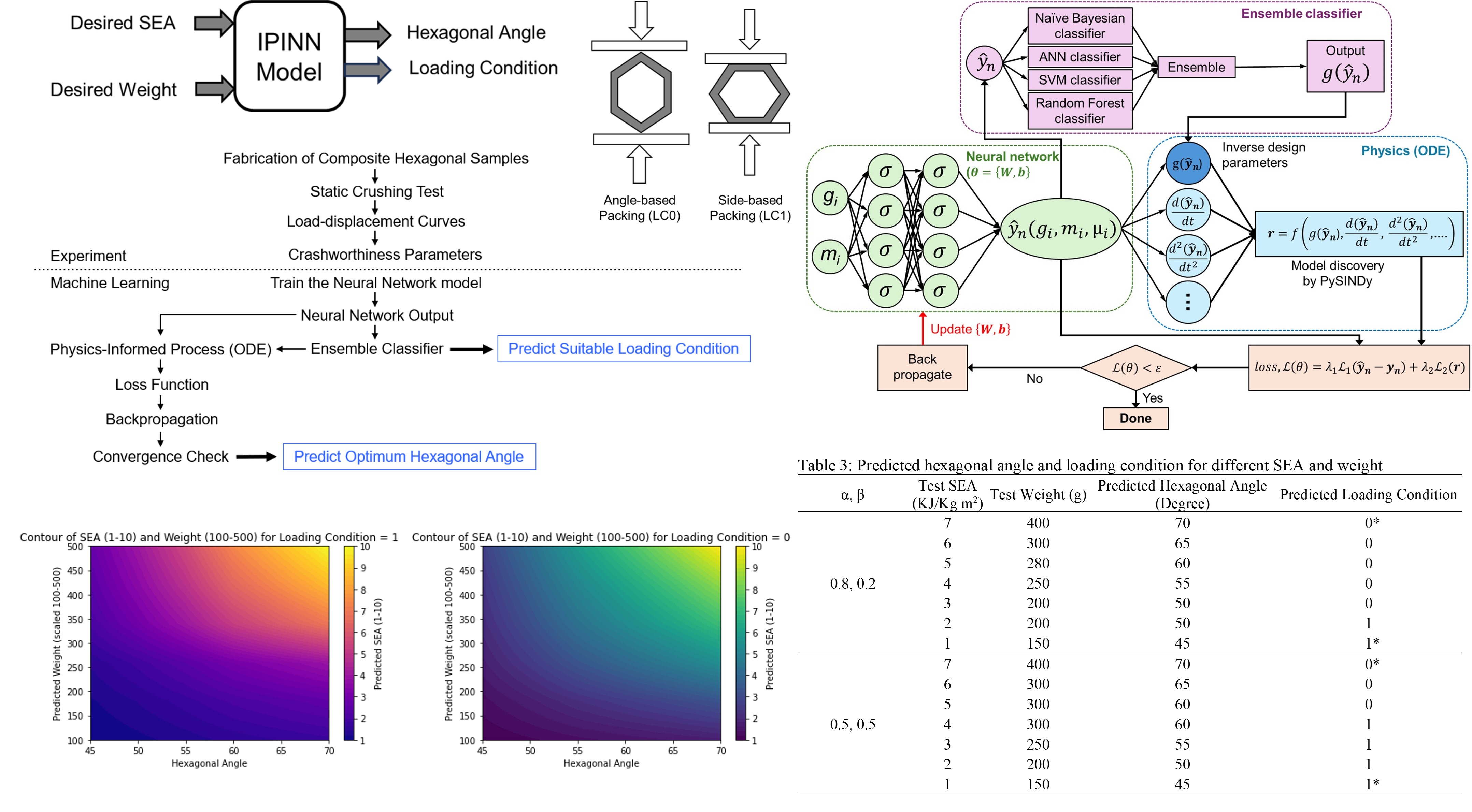

To overcome these limitations, this study introduces a novel Inverse Physics-Informed Neural Network (IPINN) framework for optimizing the crashworthiness of hexagonal ring structure of (1) woven roving glass/epoxy composite and (2) aluminium. The IPINN uniquely integrates experimental data with physics-based constraints through three key steps:

- Forward-Inverse Coupling: A forward Physics-Informed Neural Network (PINN) learns the nonlinear relationship between design parameters (e.g., hexagonal interior angles, loading rates) and crashworthiness metrics, including Specific Energy Absorption (SEA) and structural weight. This is coupled with an inverse model that rapidly identifies optimal geometries for user-defined performance targets.

- Sparse System Identification via PySINDy: Governing equations governing deformation dynamics are extracted from limited experimental and simulated data using the Sparse Identification of Nonlinear Dynamical Systems (PySINDy) method. This ensures the model prioritizes dominant physics-driven trends over black-box correlations.

- Ensemble Classification for Stability: A hybrid classifier combining Naïve Bayes, Support Vector Machines (SVM), Random Forest, and Artificial Neural Networks (ANNs) filters physically inconsistent inverse predictions, enhancing robustness and interpretability.

The framework is validated through quasi-static and dynamic compression tests on hexagonal rings of woven roving glass/epoxy composites and aluminium, with results demonstrating a 20–30% improvement in SEA for interior angles between 65° and 70°, achieved through controlled interlaminar stress distribution and delayed delamination. Crucially, the IPINN requires 60–80% less training data than conventional ML models while maintaining computational efficiency (<30 minutes per design iteration).

By bridging sparse experimental data with mechanistic principles, this work advances crashworthiness optimization in three ways: (1) It provides a physics-consistent, data-efficient inverse design tool for metals and composites; (2) It quantifies the role of hexagonal angles in mitigating anisotropic failure; (3) It offers a template for lightweight material development in resource-constrained industrial environments. The framework’s ability to generalize beyond training domains supports its adoption in safety-critical applications, from electric vehicle battery housings to helicopter subfloor structures, aligning with Industry 4.0’s demands for sustainable, resilient engineering solutions.

References:

[1] Elmarakbi A. Advanced composite materials for automotive applications: Structural integrity and crashworthiness: John Wiley & Sons, 2013.

[2] Sreejith M, Rajeev RS. 25 - Fiber reinforced composites for aerospace and sports applications. In: Joseph K, Oksman K, George G, Wilson R, Appukuttan S, editors. Fiber Reinforced Composites: Woodhead Publishing; 2021. p. 821-59.

[3] Alghannam AA, Soliman MS, Seikh AH, Alnaser IA, Fouly A, Mohammed JA, et al. Investigation on mechanical properties and corrosion resistance of Ti-modified AA5083 aluminum alloy for aerospace and automotive applications. Scientific Reports. 2023;13:11535.

[4] Wilbert A, Jang WY, Kyriakides S, Floccari JF. Buckling and progressive crushing of laterally loaded honeycomb. International Journal of Solids and Structures. 2011;48:803-16.

[5] Kazi M-K, Eljack F, Mahdi E. Optimal Filler Content for Cotton Fiber/PP Composite based on Mechanical Properties using Artificial Neural Network. Composite Structures. 2020:112654.