2025 AIChE Annual Meeting

(390b) Pathway to Sustainable Olefin Production Via Sector Coupling: Techno-Economic and Life Cycle Assessments of Naphtha-Methanol to Olefin Process Utilizing Blast Furnace Gas

Authors

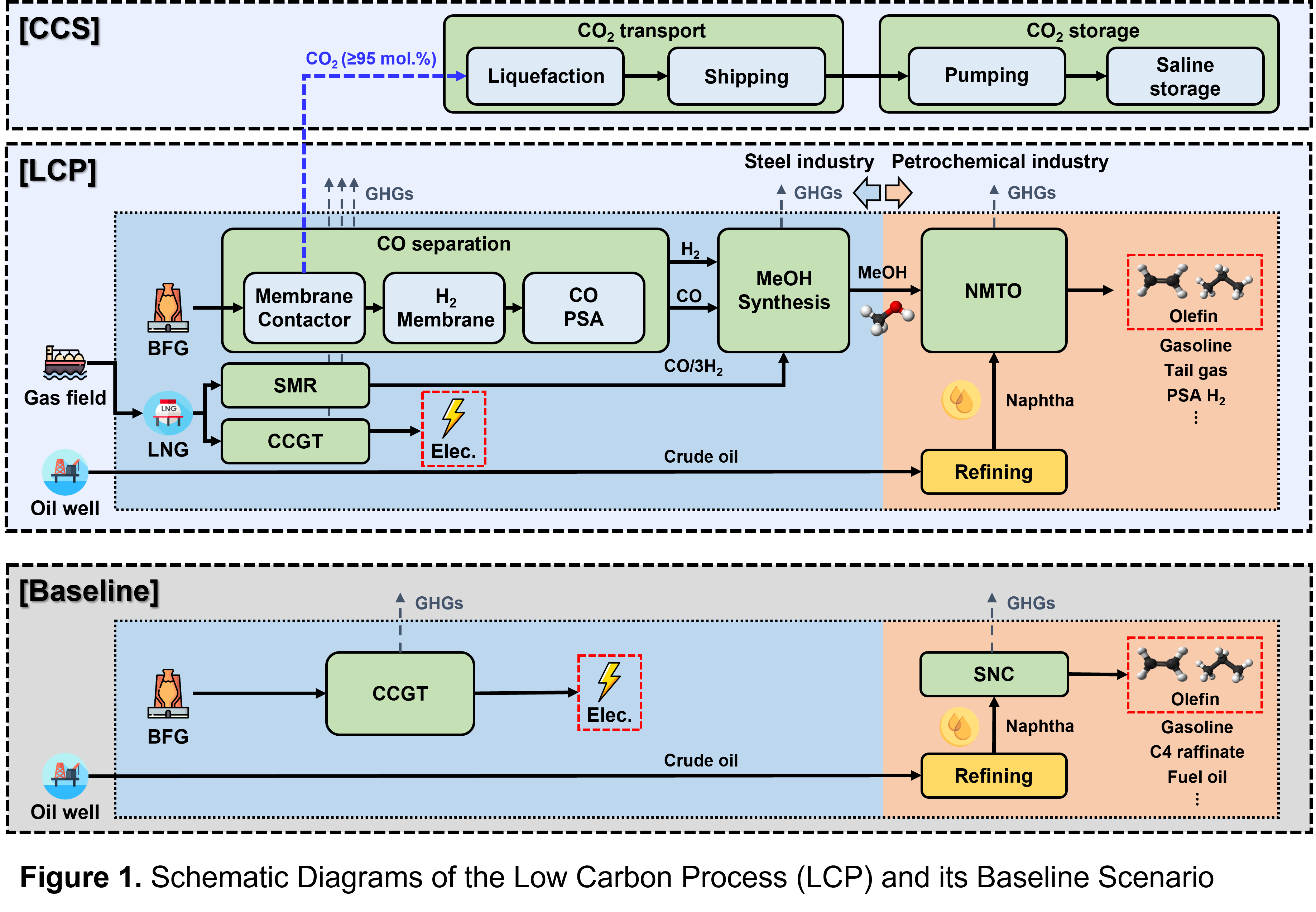

Major GHG emission sources include direct emissions from the heat supply in the SMR unit and indirect emissions associated with the production of naphtha used as a feedstock in the NMTO process. Meanwhile, it was found that carbon dioxide (CO₂) present in the BFG, which is removed in the CO separation process, still acts as a factor hindering the mitigation of GHG emissions. Since this CO₂ can be separated at high purity (95 mol.%) within the LCP, we consider a scenario of carbon capture and storage (CCS) to mitigate GHG emissions further. Economic analysis shows that naphtha constitutes the largest portion of the production costs among raw materials, followed by fixed costs and depreciation. Moreover, a Sobol sensitivity analysis is conducted to identify which life cycle inventories (LCIs) used in our LCA and material prices affect the results primarily. We then evaluate the feasibility of adopting carbon-reducing olefin production processes in different countries (such as China, USA, and Germany) and specific price conditions for sustainable operation.

Reference

[1] Korea Energy Agency. (2023). 2022 statistics on energy consumption and greenhouse gas emissions in the industrial sector: Mining and manufacturing. Korea Energy Agency.