2025 AIChE Annual Meeting

Oxidation Model Development for Metallic Fuel in a Nuclear Reactor

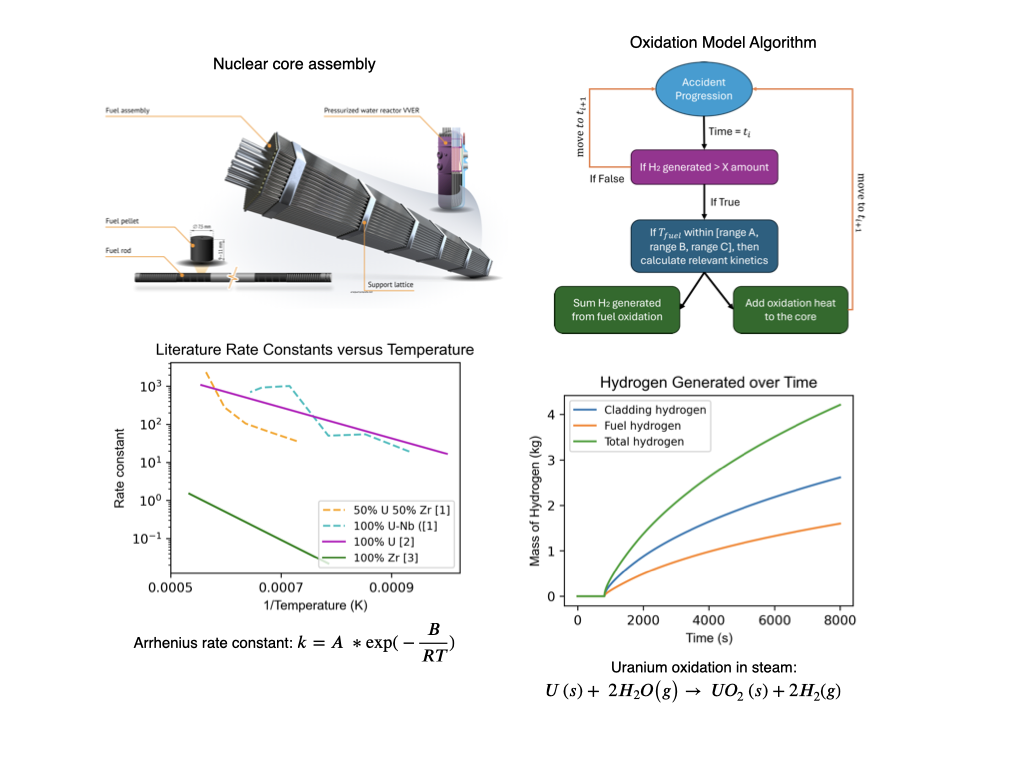

Oxidation of metallic reactor materials is a safety hazard as it weakens the metal and generates heat and hydrogen gas2. In traditional nuclear fuel rods, steam exposure will only oxidize the cladding, not the ceramic fuel pellets. But the Lightbridge metal fuel alloy could oxidize in steam, as we postulate, if cladding is compromised but not fully failed. The goal of our investigation is to develop a model to calculate the oxidation products during an accident scenario. Finally, we evaluate the fuel transient behavior by modelling a loss of cooling reactor accident.

We utilize MELCOR code for our computational framework for nuclear reactor accident analysis, specifically the NuScale 160 MWth design, a Small Modular Reactor1. MELCOR has no existing function for the oxidation of fuel, so to account for the oxidation reaction, we implemented specialized control functions. These functions calculate and add the oxidation products to the simulation. Kinetic parameters for the Lightbridge fuel are necessary for the oxidation calculations.

Oxidation kinetics can follow various rate laws depending on the reaction mechanism, such as linear or parabolic. Kinetic data is necessary for finding the hydrogen and heat generation but is limited for the alloy of interest. Steam oxidation studies on U-Zr alloys of varying compositions found that oxidation resistance generally increased with Zr wt% due to its stable g phase. Lemmon’s2 study on the (50% U-Nb)-Zr alloy was used to find parabolic rate constants as it was closest to the Lightbridge alloy composition. As the Lemmon data did not cover the entire temperature range of our simulation, the upper and lower bound for the kinetics are set at 100% U and 100% Zr using the rate laws from Wilson et al.5 and Urbanic4, respectively. The data was fit to derive rate constants and the rate law for the model:

Considering the MELCOR limitations in studying unconventional fuel, the final model integrates the oxidation model with the reactor core. This allows us to simultaneously assess the oxidation impact of the Lightbridge-like metallic fuel and cladding. We assume the worst-case scenario where once the cladding oxidizes, the fuel also initiates oxidation. The results from our model demonstrate that the fuel oxidation would accelerate the fuel heat up and cause failure to occur a few hours earlier. This indicates an area for further safety analysis of the fuel materials.

References

[1] Allaf, M. A., Ejnik, G., Zaccomer, E., Jung, W. H., Corradini, M., & Duarte, J. P. (2025). Investigating the Role of Chromium-Coated Clad During Accident Progression for an SMR Using MELCOR. Nuclear Technology, 1–19. doi.org/10.1080/00295450.2025.2505808

[2] Lemmon, A. W. (1957). The reaction of steam with uranium and with various uranium-niobium-zirconium alloys at high temperatures. doi.org/10.2172/4319193

[3] Shirvan, Koroush, and Mujid S. Kazimi. (2014). Three dimensional considerations in thermal-hydraulics of helical cruciform fuel rods for LWR power uprates. Nuclear Engineering and Design, 270, 259-272. doi.org/10.1016/j.nucengdes.2014.01.015

[4] Urbanic, V.F. (1978). High-temperature oxidation of zircaloy-2 and zircaloy-4 in steam. Nuclear Materials, 75(2), 251-261. doi.org/10.1016/0022-3115(78)90006-5.

[5] Wilson, R. E., Barnes, C., Koonz, R., & Baker, L. (1966). Isothermal Reaction of Uranium with Steam Between 400 and 1600°C. Nuclear Science and Engineering, 25(2), 109–115. doi.org/10.13182/NSE66-A17727