2025 AIChE Annual Meeting

(347e) Optimizing Syngas Production and Tar Emissions with a Dual-Bed Reactor in Catalytic Biomass Gasification

Authors

Brandon Robinson, West Virginia University

Changle Jiang, West Virginia University

Debangsu Bhattacharyya, West Virginia University

Jianli Hu, West Virginia University

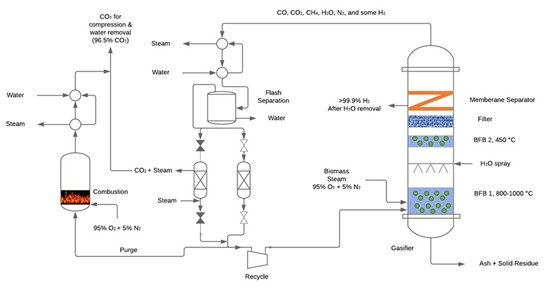

This DOE-funded research aims to develop and test an innovative two-stage bubbling fluidized bed (BFB) gasifier equipped with a hydrogen separation membrane to produce clean hydrogen from biomass. Advancing biomass gasification technology requires innovation and optimization in reactor design, particularly for producing cleaner syngas with a focus on hydrogen generation. The system's configuration is depicted in Figure 1. To enhance performance, key parameters such as feeding rate, minimum fluidization velocity, and flow-to-solids ratio have been optimized. Additionally, hot gasifier tests were conducted to assess how catalyst material and gas distributor design influence gasifier performance. The design of the gas distributor and the catalyst material's impact on reaction kinetics, gas quality, and flow distribution were found to significantly affect fluidized bed efficiency. The first catalyst bed is optimized for syngas production, while the second is designed to decompose tar. The primary objective is to produce high-quality, clean syngas with tar concentrations below 1%. Testing was conducted across a range of solid feed rates (0.096 g/min to 3.6 g/min), and it was found that a feed rate of 1.125 g/min is optimal for minimizing tar yield to below 1%. Additionally, the syngas composition was observed to be 45% H2 and 36% CO. Achieving this outcome depends on several factors, including catalyst design, gasifying agent choice, and precise control of the feeding rate. By optimizing these variables, we aim to minimize tar formation and maximize syngas quality, thereby enhancing the reliability and efficiency of the gasification process. This research provides valuable insights into reactor design and operating parameters, contributing to the future development of biomass gasification technologies.

Keywords: Bubbling Fluidized Bed; Clean Hydrogen, Biomass Gasification; Tar Reduction